Catalyst for 1,1-difluoroethane producing vapor process

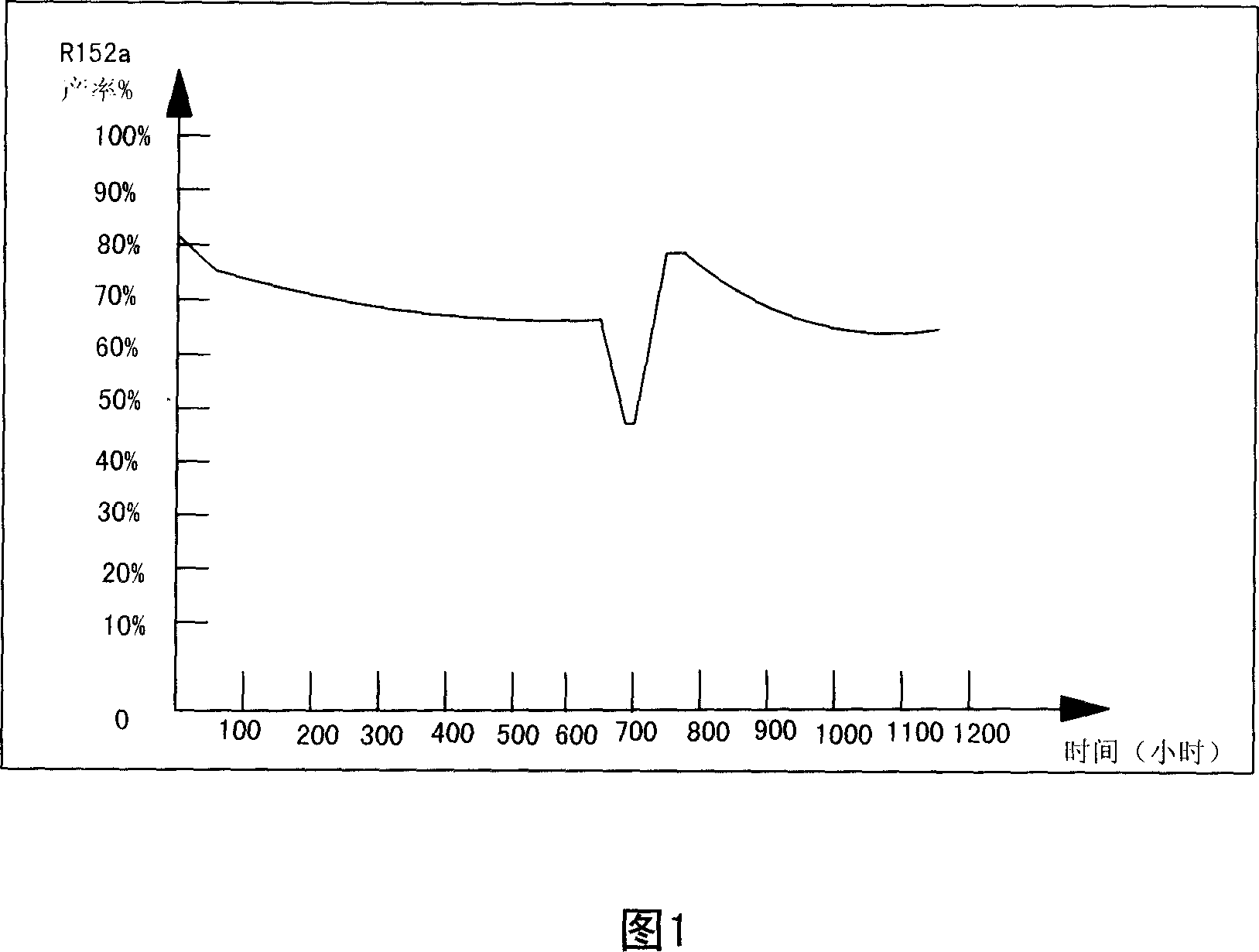

A difluoroethane and catalyst technology, which is applied in the field of gas-phase production, can solve the problems of serious environmental pollution of the catalyst, short service life of the catalyst, deactivation of the catalyst, etc., and achieves easy activation and regeneration, good stability, and high space-time yield. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment one: Catalyst composition: Cr: Co=1: 0.2 (the following examples are the molar ratio of each element)

[0024] Catalyst preparation process:

[0025] Accurately weigh 1 mol of chromium salt and 0.2 mol of cobalt salt (the salt can be nitrate, sulfate or chloride) which are easily soluble in water and dissolve in water, and the water is pure water. Then add alkaline solution (precipitating agent, which can be NaOH, KOH or NH 4 OH solution), keep PH=7-10. Filter, dry at 100°C, and bake at a low temperature in the range of 330°C to 380°C. Inert gas N was introduced during the roasting process 2 , The oxide catalyst can be prepared by extruding the calcined raw material. The components in the oxide catalyst mainly exist in the form of oxides.

[0026] After the oxide catalyst is prepared, take 100ml of the oxide catalyst and put it into a φ26*2.9 nickel tube, in the inert gas N 2 Under the protection of the hydrogen fluoride gas, the fluorination is carried...

Embodiment 2

[0029] Catalyst composition: Cr:Mg=1:0.1

[0030] Kong Rong

Embodiment 3

[0031] Example three: Cr: Co: Fe = 1: 0.2: 0.1

[0032] Kong Rong

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com