High-vanadium wear-resistant alloy material and production technique thereof

A wear-resistant alloy and production process technology, applied in the field of wear-resistant materials, to achieve the effect of increasing the number of particles, reducing the production cost of alloys, and preventing the growth of grain boundaries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

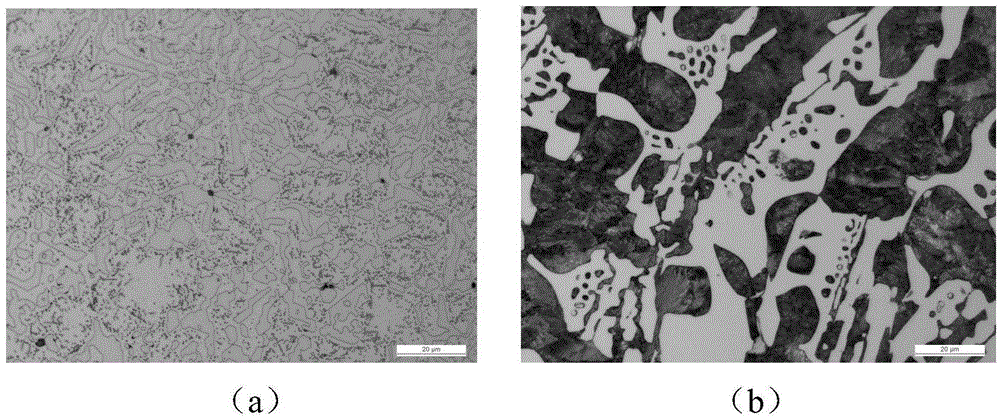

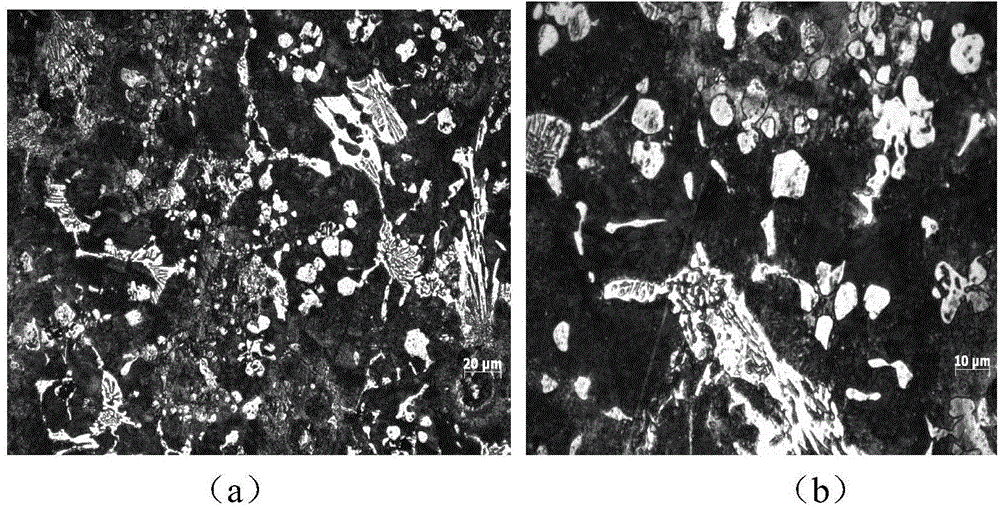

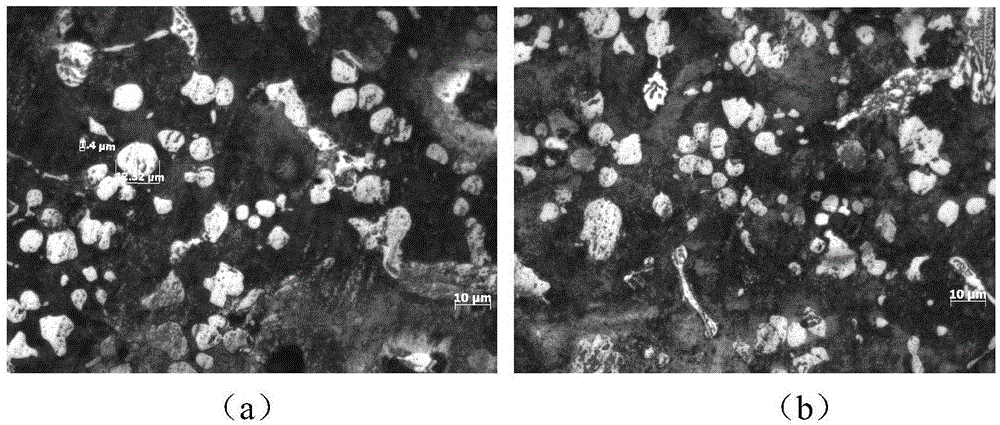

[0039] The high vanadium wear-resistant alloy material of the present invention contains (mass percentage) C: 2.7-3.5%, V: 7.5-8.5%, Si: 0.5-1.5%, Mn: 0.8-1.5%, Cr: 2.0-3.5%, Mo: 1.0-2.5%, Ti: 1.0-2.0%, S: ≤0.04%, P: ≤0.04%, and the balance is iron; among them, silicon comes from scrap steel, alloy and other raw materials.

[0040] C: Carbon is very important to the structure and performance of composite wear-resistant materials. It can not only dissolve in the matrix for solid solution strengthening, but also form the basic element of carbide reinforcement phase, and can also promote martensitic transformation. , Improve the hardenability of composite wear-resistant materials. Too much carbon content will increase the brittleness of the material, and too little will reduce the number of carbide-enhanced phases and reduce its wear resistance. Therefore, the C content in this material is controlled at 2.7-3.5%.

[0041] V: Vanadium is a strong carbide forming element. It is e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| microhardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com