Cement-free iron runner castable for skimmer preformed unit

A cement-free technology for iron trench castables, which is applied in the field of materials, can solve the problems of the site being greatly affected by high temperature, the failure of silica sol freezing, and troublesome construction, so as to improve the thermal strength and the ability to Slag performance, enhance the effect of slag resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

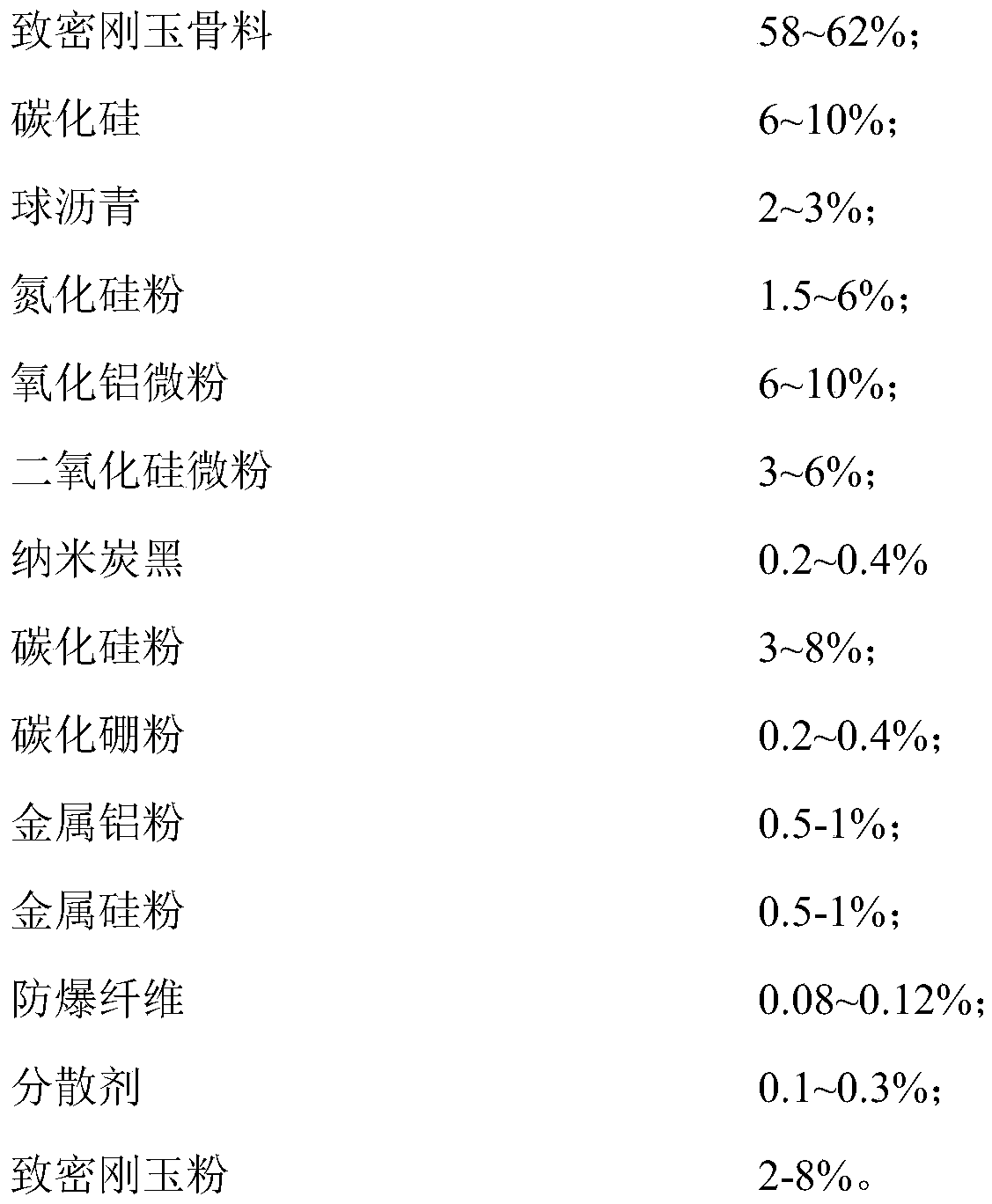

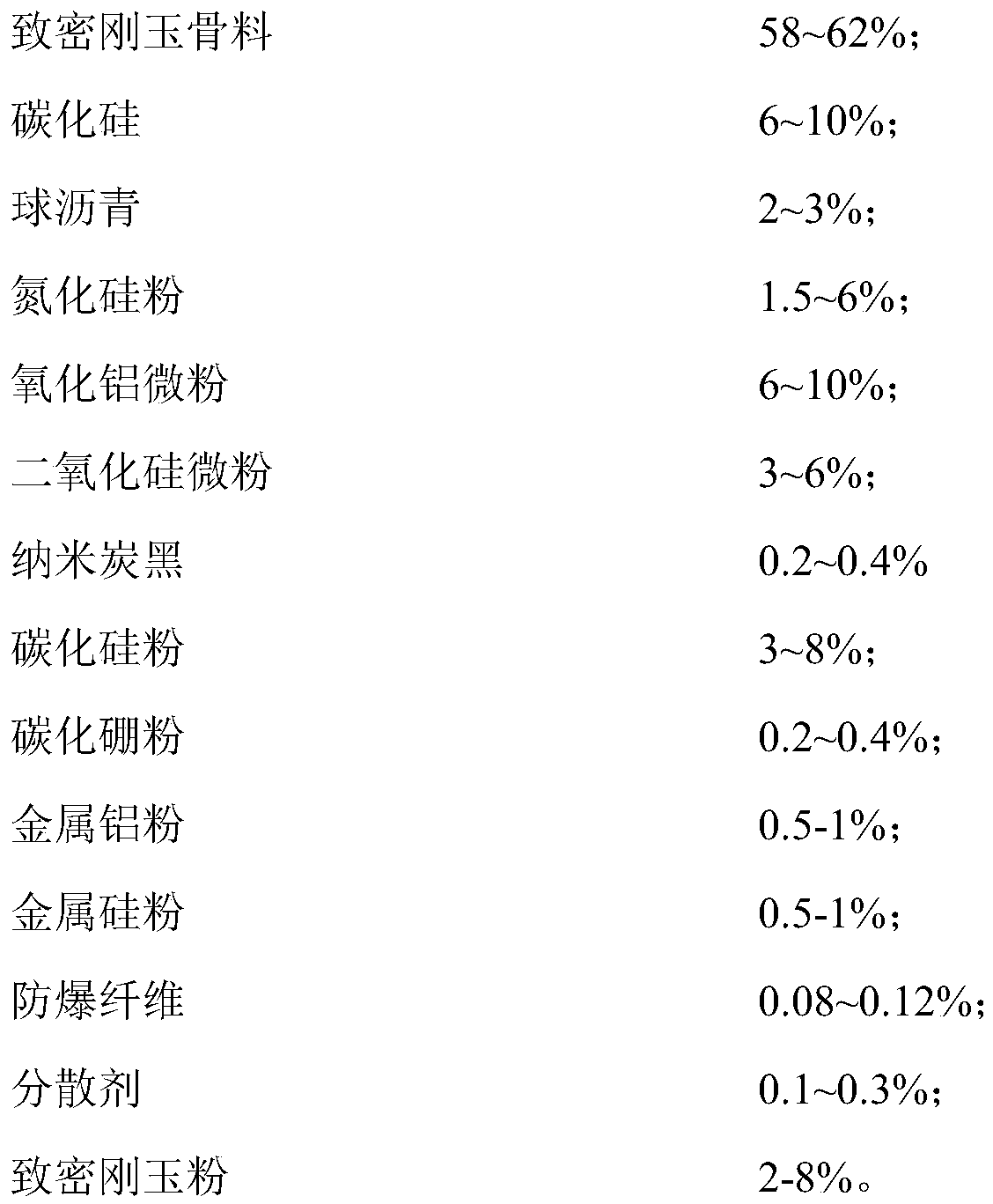

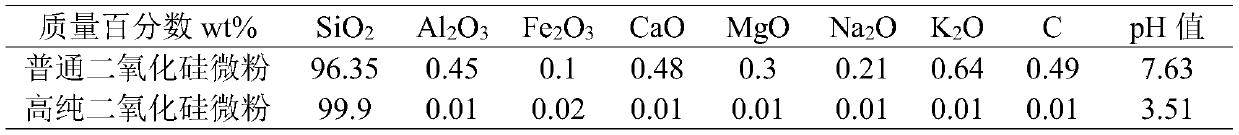

[0034] A cementless iron ditch castable for skimmer prefabricated parts, each component and its mass percentage are: dense corundum aggregate 56%; silicon carbide 0-1mm: 10%; ball pitch 2%; alumina Micropowder 6%; high-purity silica micropowder 6%; silicon carbide powder 8%; silicon nitride powder 1.5%; nano-carbon black 0.3%; metal aluminum powder 0.5%, explosion-proof fiber 0.08%; 1% boron carbide powder; 0.2% boron carbide powder; 6.32% dense corundum powder. The raw materials were weighed according to the above proportions and fully mixed; then water was added (the mass of water was 3.2% of the total mass of each raw material) and stirred evenly, then vibrated and formed; The heat treatment was carried out for 24 hours, and the cementless iron ditch castable sample for the skimmer prefabricated parts was prepared.

[0035] The performance test of the prefabricated part of the skimmer prepared in this example was performed with a cementless iron ditch castable sample, and ...

Embodiment 2

[0039]A cementless iron ditch castable for skimmer prefabricated parts, each component and its mass percentage are: dense corundum aggregate 62%; silicon carbide 0-1mm: 6%; ball pitch 2%; alumina Micropowder 6%; high-purity silica micropowder 5%; silicon carbide powder 3%; silicon nitride powder 6%; nano-carbon black 0.2%; metal aluminum powder 0.6%, explosion-proof fiber 0.1%; 0.6% boron carbide powder; 0.3% boron carbide powder; 8% dense corundum powder. The raw materials were weighed according to the above proportions and fully mixed; then water was added (the mass of water was 3.2% of the total mass of each raw material) and stirred evenly, then vibrated and formed; The heat treatment was carried out for 24 hours, and the cementless iron ditch castable sample for the skimmer prefabricated parts was prepared.

[0040] The performance test of the prefabricated part of the skimmer prepared in this example was performed with the cementless iron ditch castable sample, and the ...

Embodiment 3

[0044] A cementless iron ditch castable for skimmer prefabricated parts, the components and their mass percentages are: dense corundum aggregate 58.93%; silicon carbide 0-1mm: 10%; ball pitch 2.5%; alumina Micropowder 10%; high-purity silica micropowder 3%; silicon carbide powder 8%; silicon nitride powder 3%; nano-carbon black 0.4%; metal aluminum powder 1%, explosion-proof fiber 0.08%; 0.5% of boron carbide powder; 0.4% of boron carbide powder; 2% of dense corundum powder. The raw materials were weighed according to the above proportions and fully mixed; then water was added (the mass of water was 3.2% of the total mass of each raw material) and stirred evenly, then vibrated and formed; The heat treatment was carried out for 24 hours, and the cementless iron ditch castable sample for the skimmer prefabricated parts was prepared.

[0045] The performance test of the prefabricated part of the skimmer prepared in this example was performed with a cementless iron ditch castable...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com