A kind of non-chloride ion potassium salt water-locking agent for oil well cement and preparation method and application

A technology of oil well cement and ionic potassium, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of long waiting setting time, slow hydration rate of cement slurry, long initial setting time, etc., to achieve accelerated setting and Hardening, promoting formation and development, and improving the effect of impermeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

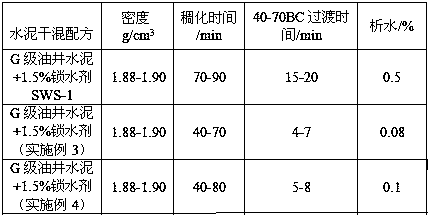

Examples

Embodiment 1

[0018] In order to solve the problem that the existing cement slurry has a long waiting time, which can easily cause oil, gas, and water flooding, resulting in poor cementing quality and strong corrosion to the casing, this embodiment provides a non-chloride ion cement for oil well cement. The potassium salt water-locking agent is composed of the following materials in mass percentage: 40-60% potassium salt, 10-30% alkali, and 20-40% sodium silicate.

[0019] Principle of the present invention:

[0020] Potassium ions in the formula have a coagulation-promoting effect, and the hydration reacts rapidly, providing a skeleton of the cohesion structure for the cement paste, promoting the formation and development of cement hydration products, and accelerating the coagulation and hardening of cement; the sodium ions in sodium silicate React with cement to form colloid, which can fill the pores between cement, make the structure of cement stone compact, high density, and improve imp...

Embodiment 2

[0023] On the basis of Example 1, this example provides a non-chloride ion potassium salt water-locking agent for oil well cement, which is composed of the following materials in mass percentage: 40% potassium salt, 30% alkali, 30% sodium silicate %.

[0024] Preparation process: Add 400 Kg of potassium salt, 300 Kg of alkali, and 300 Kg of sodium silicate to a mixer, mix and stir for 40 minutes.

[0025] In this embodiment, the potassium salt is potassium sulfate, and the base is sodium hydroxide. Sodium ions in sodium silicate react with cement to form colloid, which can fill the pores between cement, make the structure of cement stone dense, high density, and improve impermeability.

Embodiment 3

[0027] On the basis of Example 1, this example provides a non-chloride ion potassium salt water-locking agent for oil well cement, which is composed of the following materials in mass percentage: 50% potassium salt, 20% alkali, 30% sodium silicate %.

[0028] Preparation process: Add 500 Kg of potassium salt, 200 Kg of alkali, and 300 Kg of sodium silicate into a mixer, and mix and stir for 30 minutes.

[0029] In this embodiment, the potassium salt is potassium sulfate, and the base is calcium hydroxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com