Waste fluorine gypsum activating technique

A fluorogypsum and modification technology, which is applied in the field of solid waste resource treatment, can solve the problems of unsatisfactory properties of modified fluorogypsum, high cost of modification of fluorogypsum, narrow application fields, etc., to achieve non-toxic and harmless products, The effect of reasonable raw material composition and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with the accompanying drawings, the implementation of the novel fluorogypsum modification technology will be further described.

[0030] In the following examples, it is the mass percentage. When testing the physical properties of the hardened body of fluorine gypsum after hydration, the test pieces are all 4×4×4 test molds, and the relevant properties are carried out according to the "Building Gypsum" standard.

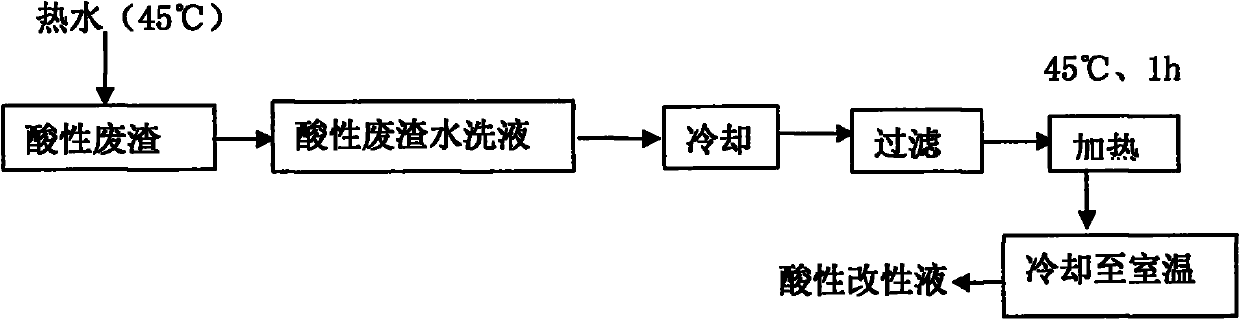

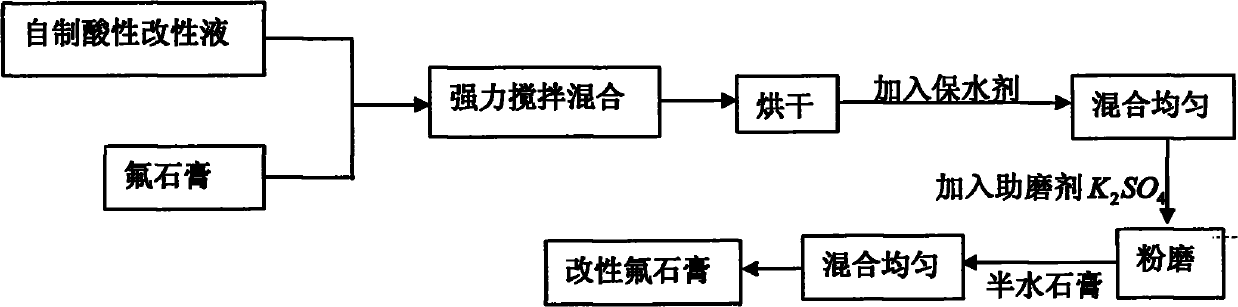

[0031] The fluorine gypsum from the storage yard was selected, and tested by a pH meter, the pH = 8.89, showing alkaline. Wash the acidic waste slag with hot water, recover the washing liquid, carry out cooling, filtration and heat treatment, and obtain the self-made acidic modified liquid after cooling under natural conditions, with a pH value in the range of 3 to 4, and contains soluble substances such as K and Al. Inorganic salt. Modifier preparation process see figure 1 shown. Fluorogypsum was neutralized with self-made acidic modif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com