High-strength hot-rolled Q and P steel and manufacturing method thereof

A manufacturing method and high-strength technology, applied in the field of wear-resistant steel manufacturing, can solve the problems of low tensile strength and low strength of steel plates, and achieve the effects of improved mechanical properties, low production costs, and reduced alloy costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with the accompanying drawings.

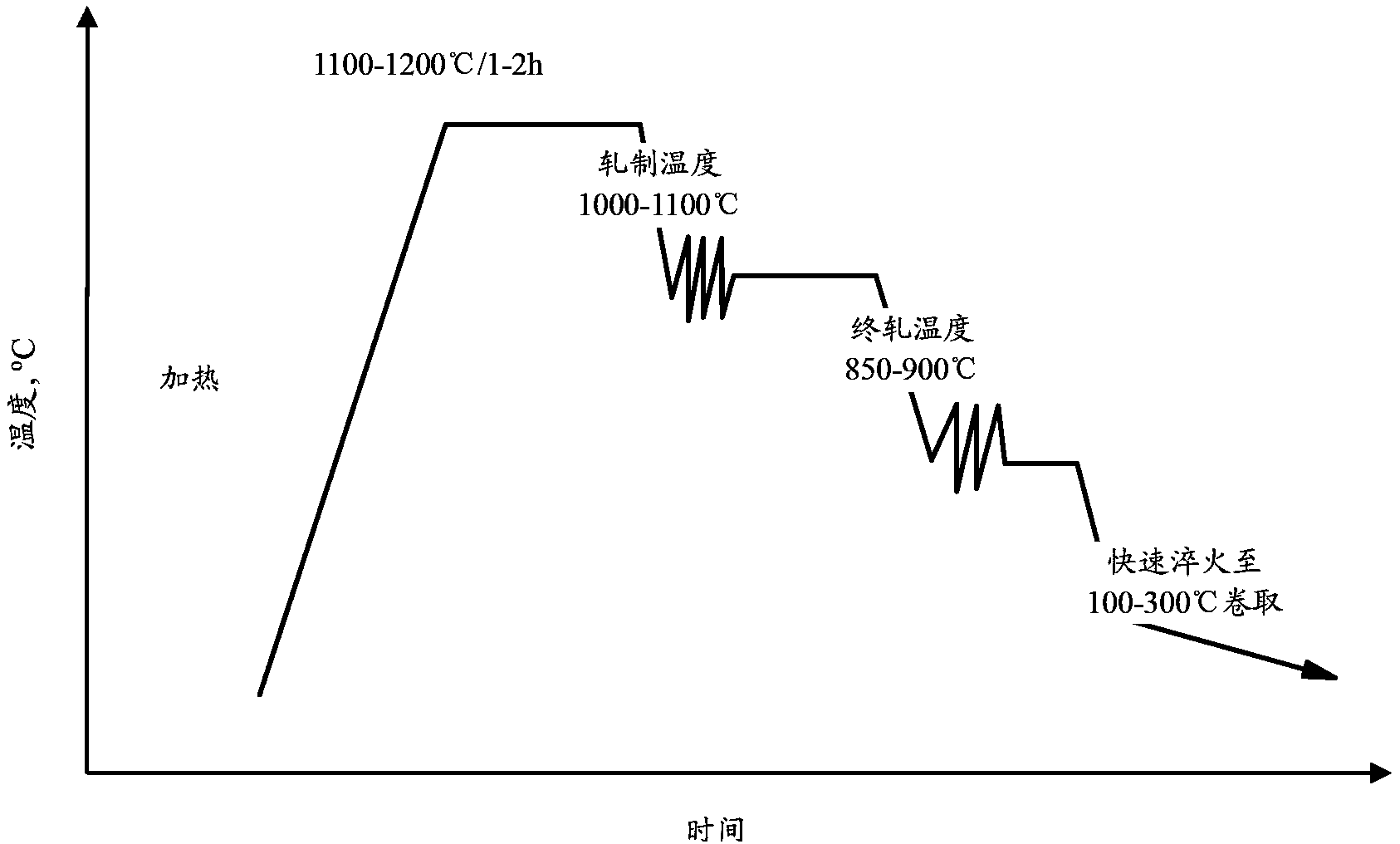

[0045] see figure 1 , the process flow of the present invention: smelting in a converter or an electric furnace, secondary refining in a vacuum furnace, and casting into billets or ingots; heating, billet or ingot heating temperature: 1100~1200°C, holding time: 1~2 hours; rolling, Rolling start temperature: 1000~1100°C, multi-pass high pressure above 950°C and cumulative deformation ≥ 50%, then the intermediate billet is heated to 900~950°C, and then rolled for the last 3~5 passes; Cooling, above the starting temperature of ferrite precipitation, that is, between 850 and 900 °C, cooling to 100 to 300 °C at a cooling rate of >50 °C / s to obtain martensite + 5% retained austenite structure, and finally Slowly cool to room temperature after coiling.

[0046] The composition of the embodiment of the present invention is shown in Table 1, and the process and performance ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com