Manufacturing method of steel

A production method and molten steel technology, applied in the field of iron and steel metallurgy, can solve problems such as the inability to guarantee the stable yield of N element, and achieve the effect of increasing the yield and stabilizing the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

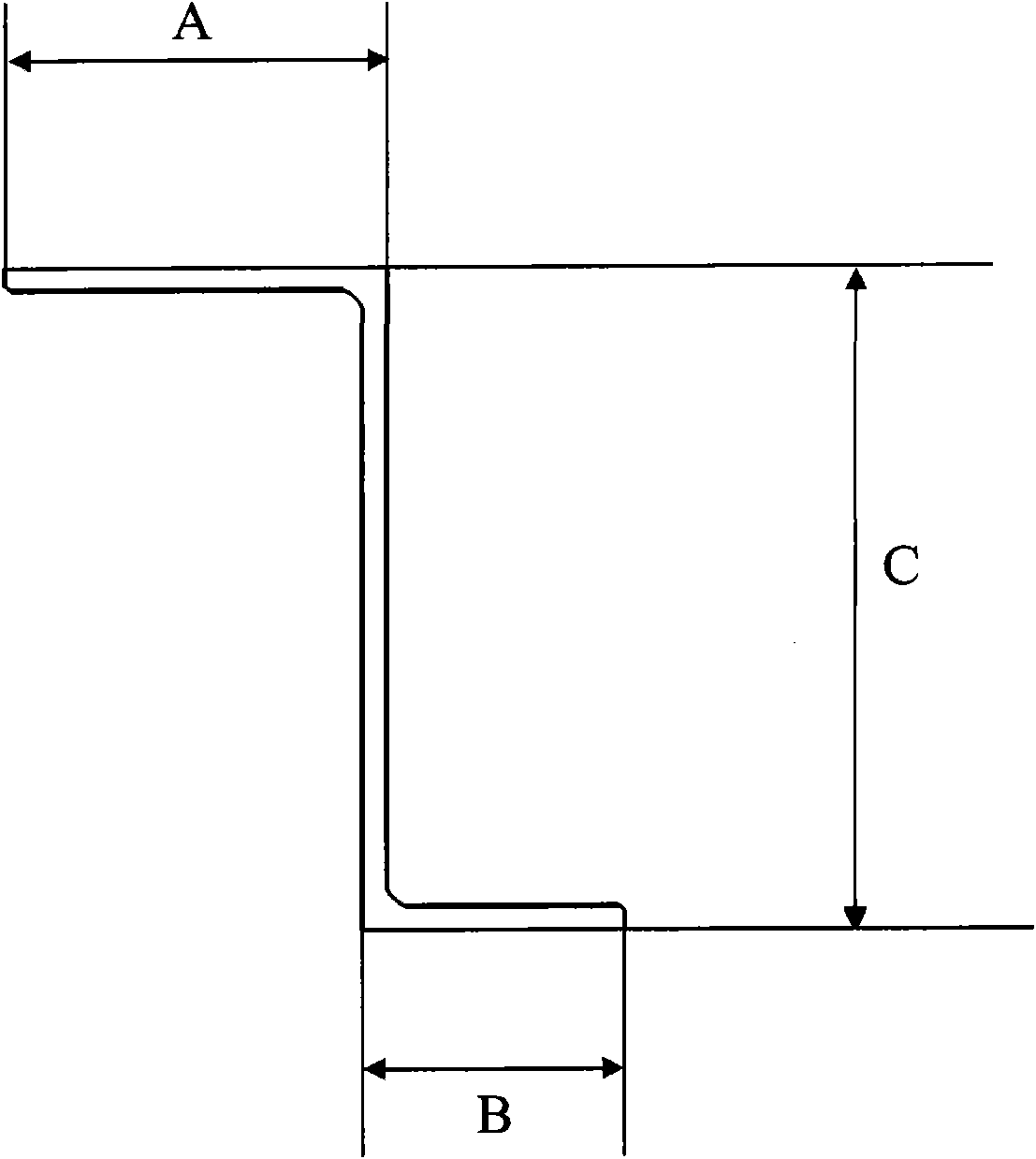

[0056] This embodiment is used to produce shape as figure 1 The high-strength atmospheric corrosion-resistant steel shown.

[0057] In a converter with a nominal capacity of 120 tons (the actual tapping amount is between 125 and 135 tons), molten iron containing 4.3% C and capable of tapping 134 tons is added for primary smelting.

[0058] Add Cu plate and Ni plate 5 minutes before the completion of converter smelting molten steel, so that the contents of Cu and Ni in molten steel are 0.25% and 0.15% respectively. When the content of C in molten steel in converter is below 0.05%, tap steel immediately , At this time, the measured values of the chemical components of molten steel are C 0.03%, P 0.015%, and S 0.010%. When 1 / 3 of the steel is tapped, 1.0 tons of a physical mixture of lime and fluorite (including 800 kg of lime and 200 kg of fluorite) is added to the ladle, and then 320 kg of FeAl (containing 40% of Al and the rest is Fe) is added, and FeSiMn, FeSi and FeCr are...

Embodiment 2

[0064] This embodiment is used to produce shape as figure 1 The high-strength atmospheric corrosion-resistant steel shown.

[0065] In a converter with a nominal capacity of 120 tons (the actual tapping amount is between 125 and 135 tons), molten iron containing 4.2% C and capable of tapping 135 tons is added for primary smelting.

[0066] Add Cu plate and Ni plate 5 minutes before the completion of converter smelting molten steel, so that the contents of Cu and Ni in molten steel are 0.20% and 0.45% respectively. When the C content of converter molten steel is below 0.05%, immediately tap the ladle , At this time, the measured values of the chemical components of molten steel are C 0.04%, P 0.018%, and S 0.011%. When 1 / 3 of the steel is tapped, 1.0 tons of a physical mixture of lime and fluorite (including 800 kg of lime and 200 kg of fluorite) are added to the ladle, then 300 kg of FeAl (containing 40% of Al and the rest is Fe) is added, and FeSiMn, FeSi and FeCr are adde...

Embodiment 3

[0072] This embodiment is used to produce shape as figure 1 The high-strength atmospheric corrosion-resistant steel shown.

[0073] In a converter with a nominal capacity of 120 tons (the actual tapping amount is between 125 and 135 tons), molten iron containing 4.1% C and capable of tapping 131 tons is added for primary smelting.

[0074] Add Cu plate and Ni plate 5 minutes before the completion of converter smelting molten steel, so that the contents of Cu and Ni in molten steel are 0.50% and 0.25% respectively. When the C content of converter molten steel is below 0.05%, immediately tap the ladle , At this time, the measured values of the chemical composition of molten steel are C 0.05%, P 0.020%, and S 0.015%. When 1 / 3 of the steel is tapped, 1.0 tons of a physical mixture of lime and fluorite (including 800 kg of lime and 200 kg of fluorite) are added to the ladle, then 300 kg of FeAl (containing 40% of Al and the rest is Fe) is added, and FeSiMn, FeSi and FeCr are add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com