High-strength and high-toughness metastable beta titanium alloy and preparation method thereof

A beta titanium alloy, metastable technology, applied in metal rolling, metal rolling, temperature control and other directions, can solve problems such as difficulty in meeting, and achieve the effect of reducing alloy cost, simplifying processing technology, and improving yield strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

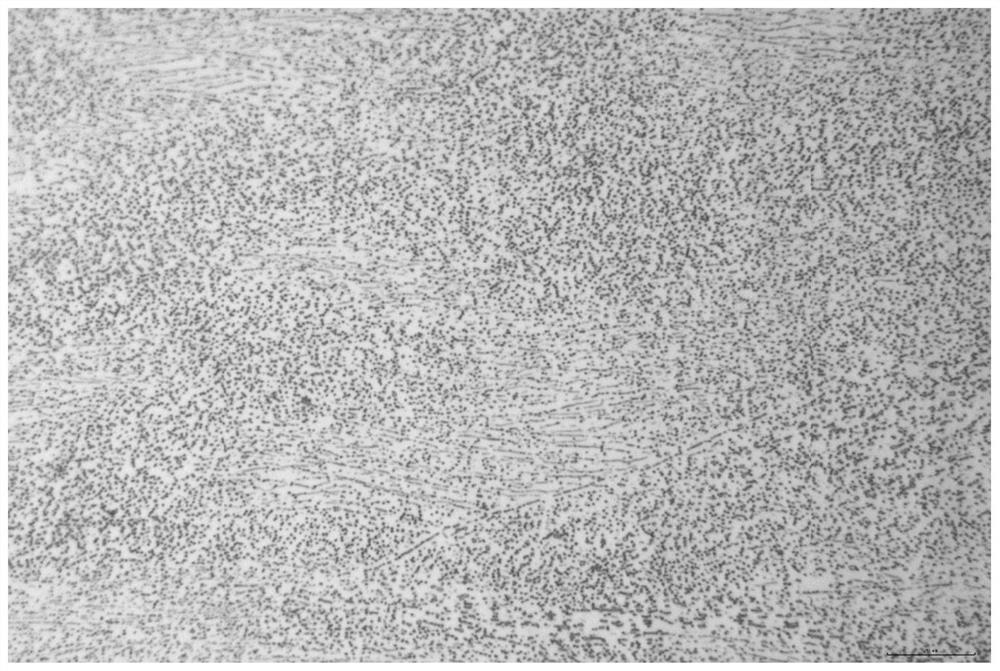

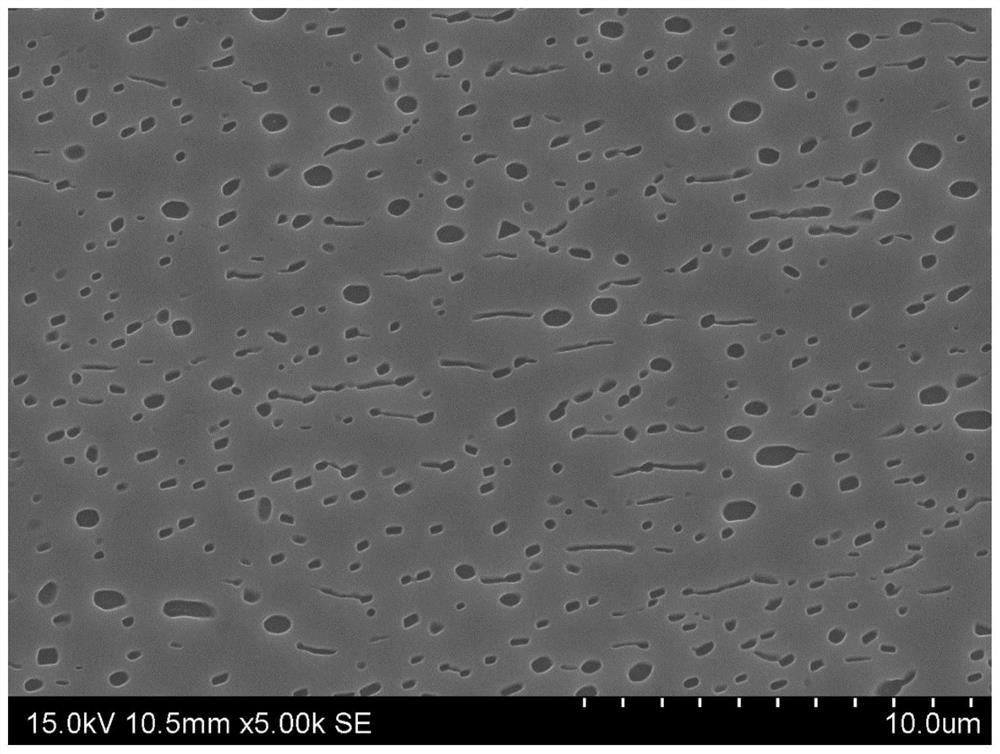

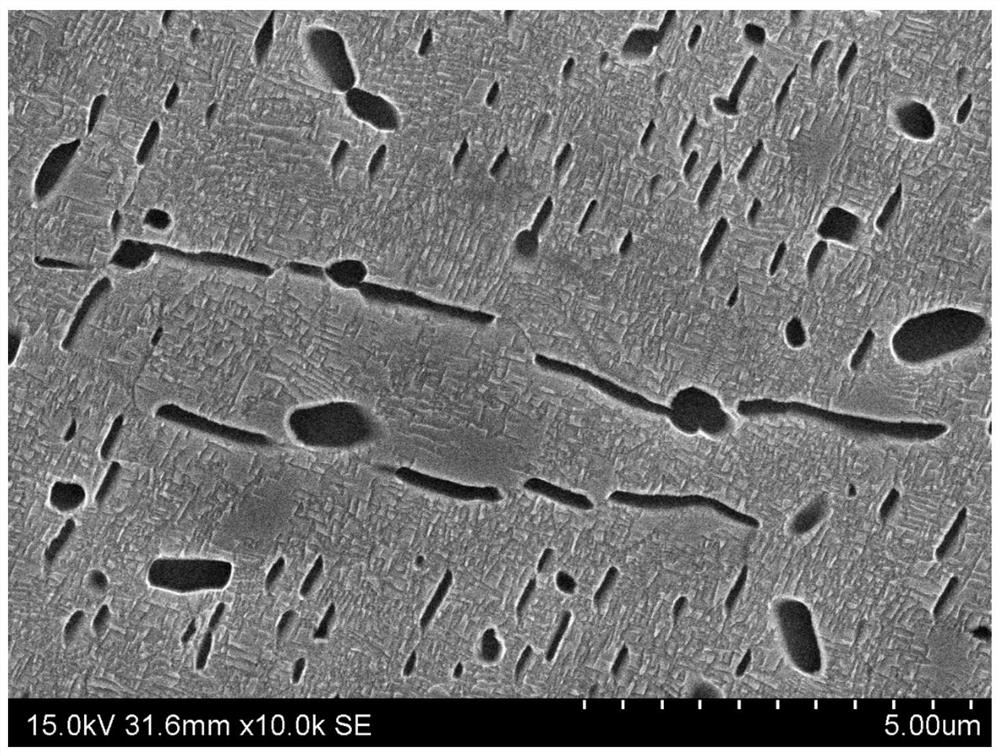

Image

Examples

preparation example Construction

[0039] A method for preparing a high-strength and high-toughness metastable β-titanium alloy, comprising the following steps:

[0040] Step 1. Mix high-purity titanium, high-purity aluminum, high-purity vanadium, high-purity molybdenum, high-purity chromium and high-purity zirconium uniformly according to the above mass percentage and load them in bulk into the furnace;

[0041]The weight percentage of each element is 4.5-5.5% of Al, 6.5-9.0% of Mo, 1-4% of V, 1.5-4% of Cr, 1-2.5% of Zr, and the balance is Ti and some other unavoidable elements. Avoid impurities.

[0042] Step 2. Under an argon atmosphere, the alloy mixture formed in step 1 is smelted multiple times, and an ingot is obtained after cooling, as follows:

[0043] Vacuum non-consumable smelting furnace is used for smelting, argon gas is introduced during the smelting process, the induction current is 450-500A, and the current frequency is 20-25KHz. After the alloy is completely melted, it is kept for 3-5 minutes,...

Embodiment 1

[0055] A method for preparing a high-strength and high-toughness metastable β-titanium alloy, comprising the following steps:

[0056] Step 1. According to the mass percentage, mix 4.5% Al, 6.5% Mo, 1% V, 1.5% Cr, 1% Zr, the balance is Ti and other unavoidable impurities, and mix the elements Evenly and bulk into the furnace;

[0057] Step 2. Use a vacuum non-consumable melting furnace for smelting. During the smelting process, argon gas is introduced, the induction current is 450A, and the current frequency is 20KHz. After the alloy is completely melted, it is kept for 3 minutes. After cooling, an ingot is obtained, and then the ingot is cast Turn over and continue smelting, the number of smelting is 2, and the ingot will be obtained after the smelting is completed.

[0058] Step 3. Homogenizing the ingot at high temperature for heat treatment at a temperature of 1000° C. for 1 hour.

[0059] Step 4. Hot-roll the homogenized ingot in the single-phase area. The hot-rolling t...

Embodiment 2

[0063] A method for preparing a high-strength and high-toughness metastable β-titanium alloy, comprising the following steps:

[0064] Step 1. According to the mass percentage, mix 4.4% Al, 8.6% Mo, 3.4% V, 1.6% Cr, 1.4% Zr, and the balance is Ti and other unavoidable impurities, and mix the elements Evenly and bulk into the furnace;

[0065] Step 2. Use a vacuum non-consumable melting furnace for melting. During the melting process, argon gas is introduced. The induction current is 475A, and the current frequency is 23KHz. After the alloy is completely melted, it is kept for 4 minutes. After cooling, an ingot is obtained, and then the ingot is cast Turn over and continue smelting, the number of smelting is 5, and the ingot will be obtained after the smelting is completed.

[0066] Step 3. Homogenizing the ingot at high temperature for heat treatment at a temperature of 1000° C. for 1 hour.

[0067] Step 4. Hot-roll the homogenized ingot in the single-phase zone. The hot-rol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com