Cr-doped Ge2Sb2Te5 phase change material, phase change memory unit and preparation method

A phase change memory and phase change material technology, applied in electrical components and other directions, can solve the problems that thermal stability cannot meet high-temperature data retention, low crystallization temperature, etc., achieve high-temperature data retention and reliability improvement, and write operation current. The effect of low, good data retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The invention provides a Cr-doped Ge 2 Sb 2 Te 5 phase change material, the Cr-doped Ge 2 Sb 2 Te 5 The general formula of phase change material is Cr x Ge 2 Sb 2 Te 5 , where x is the atomic ratio of the Cr element and satisfies 0.5<x<1.5.

[0039] Specifically, the Cr-doped Ge 2 Sb 2 Te 5 Phase change materials can be sputtered, evaporated, chemical vapor deposition (CVD), plasma enhanced chemical vapor deposition (PECVD), low pressure chemical vapor deposition (LPCVD), metal compound vapor deposition (MOCVD), molecular Beam epitaxy (MBE), atomic vapor deposition (AVD) or atomic layer deposition (ALD).

[0040] As an example, using magnetron sputtering method, with Ge 2 Sb 2 Te 5 Preparation of Cr by Co-sputtering of Alloy Target and Cr Elemental Target 1 Ge 2 Sb 2 Te 5 Thin film layer of phase change material. The process parameters are: the background air pressure is 1×10 -5 Pa, the pressure of Ar gas during sputtering is 0.2Pa, and the sputteri...

Embodiment 2

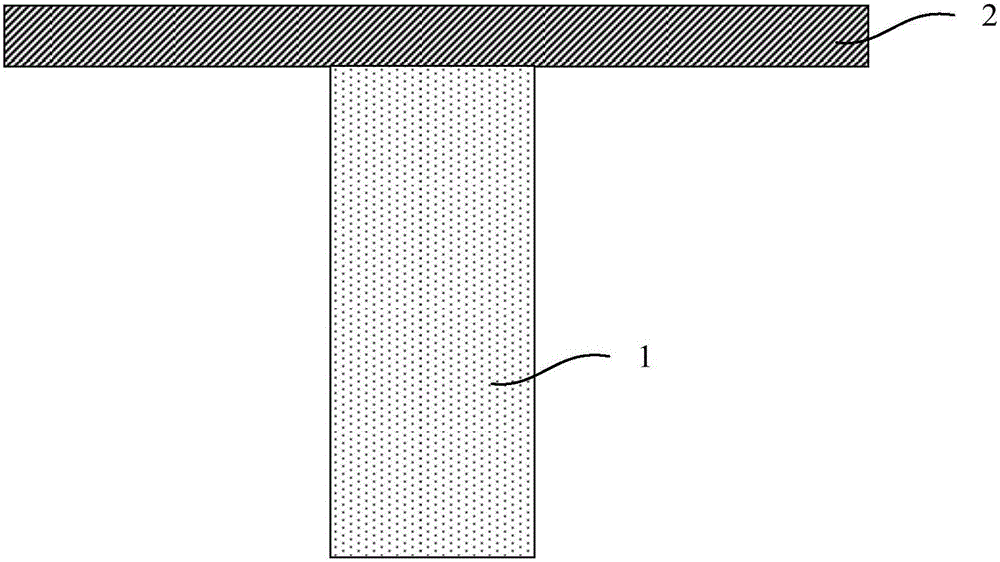

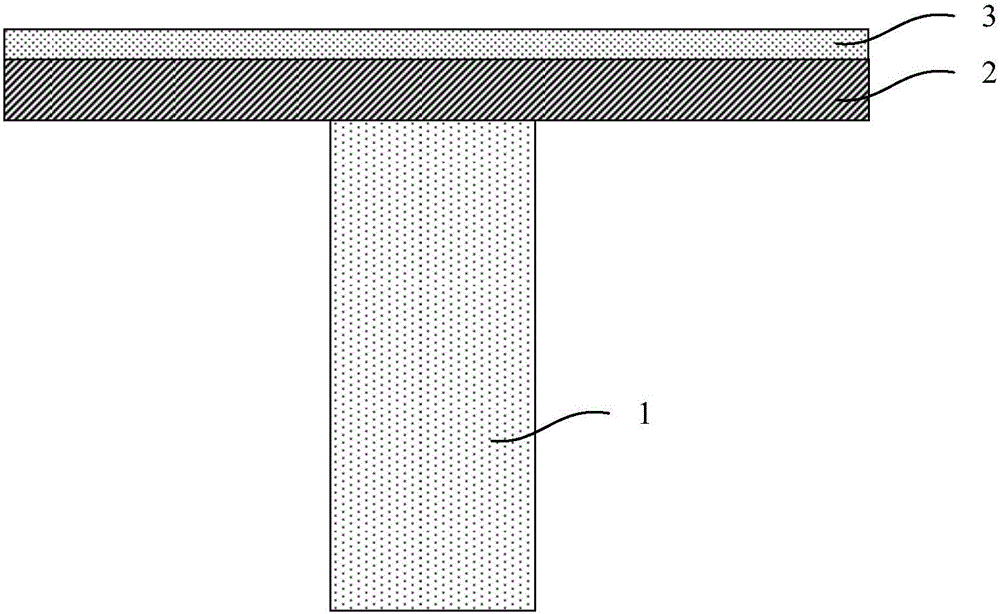

[0044] see Figure 1 ~ Figure 4 , the present invention also provides a preparation method of a phase-change memory cell, the phase-change memory adopts the Cr-doped Ge 2 Sb 2 Te 5 A phase change material, the method comprising the steps of:

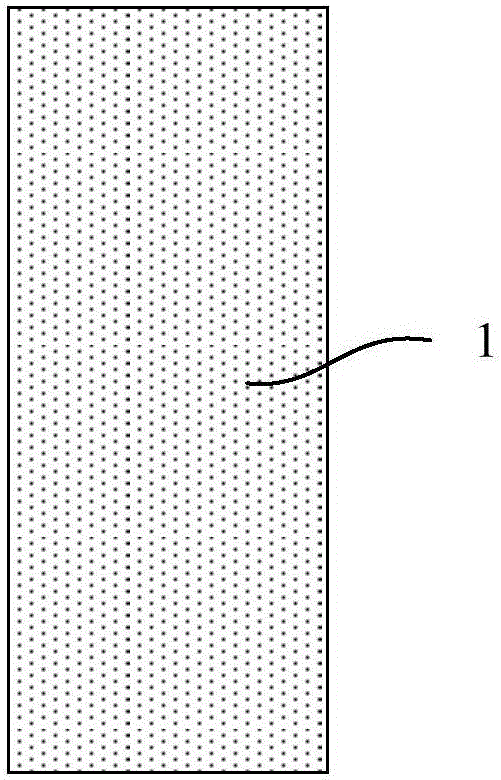

[0045] See first figure 1 , performing step S1: forming the lower electrode layer 1 .

[0046] Specifically, sputtering, evaporation, chemical vapor deposition, plasma enhanced chemical vapor deposition, low pressure chemical vapor deposition, metal compound vapor deposition, molecular beam epitaxy, atomic vapor deposition or atomic layer deposition can be used The lower electrode layer 1 is prepared by any method, and the lower electrode layer 1 is preferably prepared by the CVD method in this embodiment. The material of the lower electrode layer 1 can be one of the single metal materials W, Pt, Au, Ti, Al, Ag, Cu or Ni, or an alloy composed of any two or more of the single metal materials material, or the nitride or oxide of the ...

Embodiment 3

[0058]In this embodiment, the phase change memory unit prepared in the second embodiment is tested. see Figure 5 , which is shown as the voltage change curve (V-I diagram) of a certain device unit under the action of current excitation. It can be seen that as the current increases, the voltage value rises steadily at first, and when the current value reaches about 5 μA, the voltage value suddenly drops, indicating that the material undergoes a phase transition at this time, rapidly changing from an amorphous state to a crystalline state. Afterwards, as the current increased, the voltage value increased slightly and then stabilized, indicating that the crystallization process was further fully carried out. It can be seen that based on the new phase change material Cr 1 Ge 2 Sb 2 Te 5 The device unit has a threshold current / voltage of about 5μA / 1.2V.

[0059] See Figure 6 , is the relationship between the measured device unit resistance and the applied pulse voltage, us...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com