Fluid pipeline paint supply system and method capable of automatically changing color, metering and spraying

A fluid pipeline and paint supply technology, applied in the direction of spraying devices, liquid spraying devices, etc., can solve problems such as unstable flow supply, achieve the effects of overcoming the defects of spraying points, uniform effects, and reducing paint costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

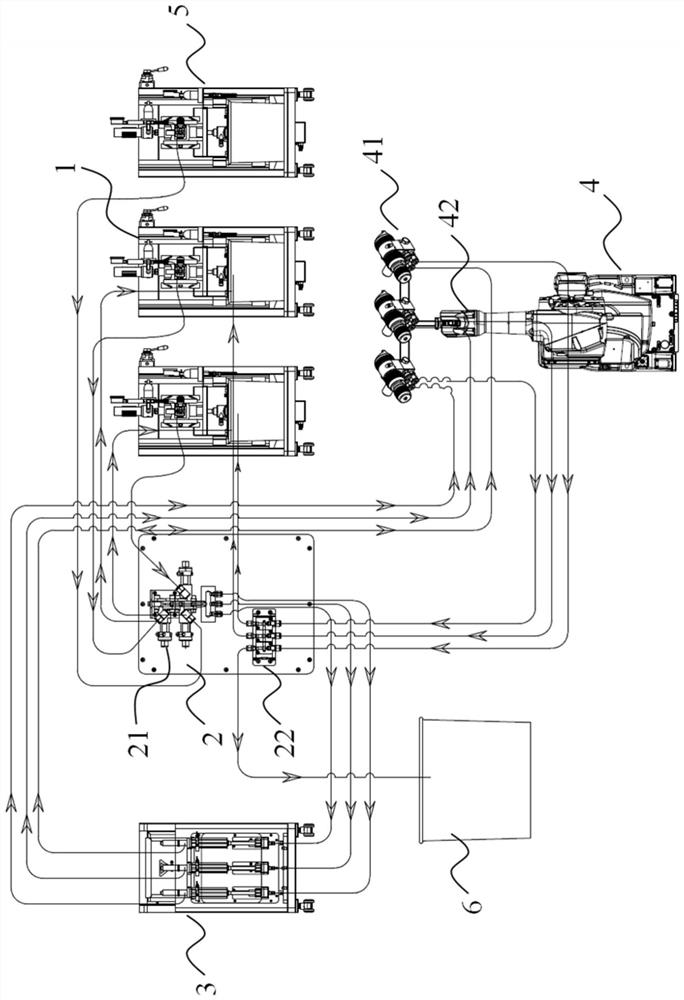

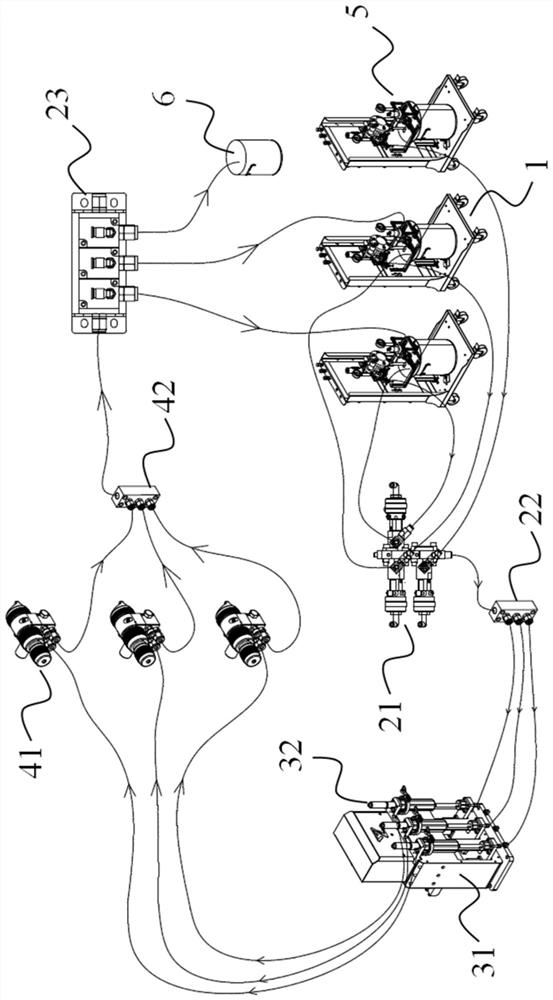

[0046] Such as Figure 1 to Figure 3 As shown, the fluid pipeline paint supply system for automatic color-changing metering spraying of the present invention mainly consists of three fluid sections, which are respectively a paint supply section, a cleaning section, and a color-changing valve return section.

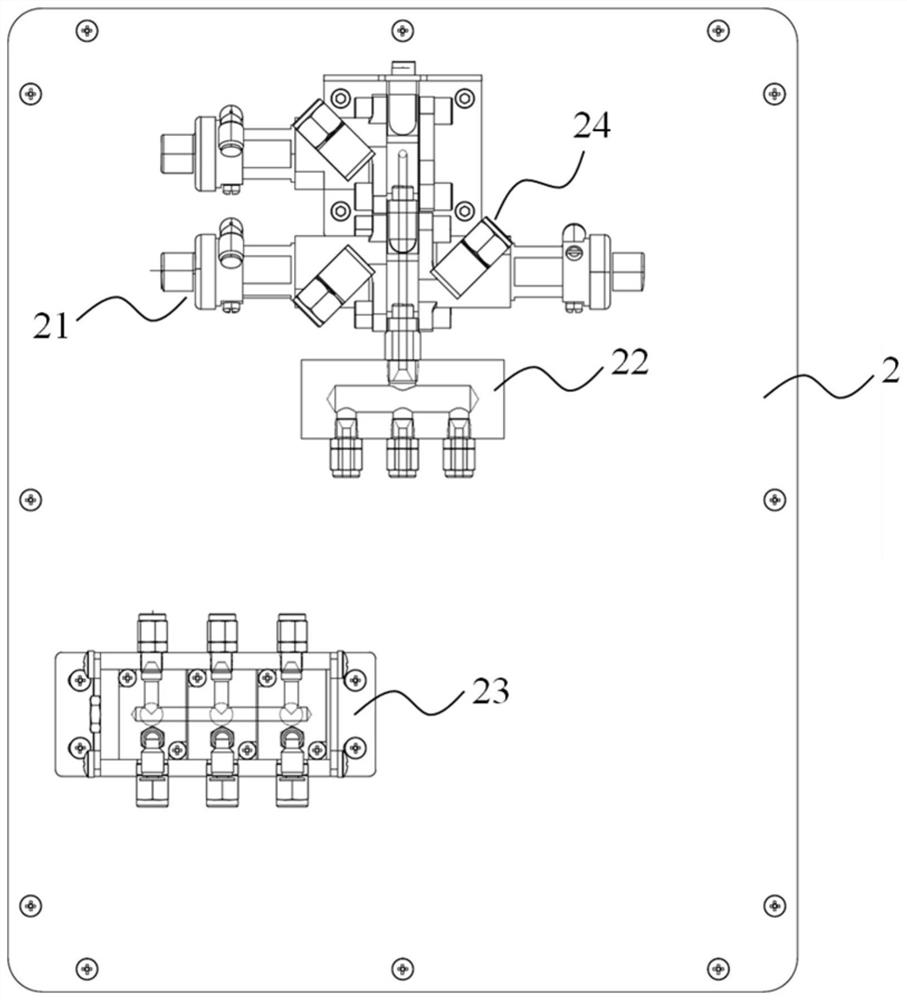

[0047] The paint supply section includes multiple paint supply systems 1, fluid plate assembly 2, metering cylinder module 3, spraying robot module 4, feed pipe, and return pipe, and the fluid plate assembly 2 includes color change valve 21, color change valve manifold Pipe 22, fluid valve group manifold 23, metering cylinder module 3 includes metering cylinder body 31, multiple plunger pumps 32, metering cylinder body 31 simultaneously drives multiple plunger pumps 32 to complete feeding and discharging actions, spraying robot module 4 Including a plurality of spray guns 41 and a spray gun manifold 42, a plurality of paint supply systems 1 are respectively connected to a...

Embodiment 2

[0056] Such as Figure 1 to Figure 3 As shown, based on the fluid pipeline paint supply system of Embodiment 1, a fluid pipeline paint supply method for automatic color-changing metering spraying of the present invention:

[0057] Including step S1. Automatic color-changing paint supply method:

[0058] S11. Multiple paint supply systems deliver paints of different colors to multiple paint channels of the color change valve, and the paint channel of each color change valve corresponds to a paint supply system of a color;

[0059] S12. Paint supply step: the color change valve 21 and the fluid valve group manifold 22 both open a paint channel for a color paint, the paint forms a closed-loop flow in the feed pipe and the return pipe, and the metering cylinder body 31 drives the plunger pump 32 execute the pumping action, close the paint channel of the color change valve 21 and the fluid valve group manifold 22 after the pumping is completed; before the spray gun is sprayed, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com