Anti-adhesion plate and manufacturing method thereof

A manufacturing method and anti-sticking plate technology, applied in ion implantation plating, metal material coating process, coating, etc., can solve the problems of high coating cost, high maintenance cost and cleaning cost, and low service life of the anti-sticking plate , to achieve the effect of reducing coating cost, good density and reducing maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following description of the embodiments refers to the accompanying drawings to illustrate specific embodiments in which the invention may be practiced. The directional terms mentioned in the present invention, such as "up", "down", "front", "back", "left", "right", "top", "bottom", etc., are only for reference to the attached drawings. direction. Therefore, the directional terms used are used to illustrate and understand the present invention, but not to limit the present invention.

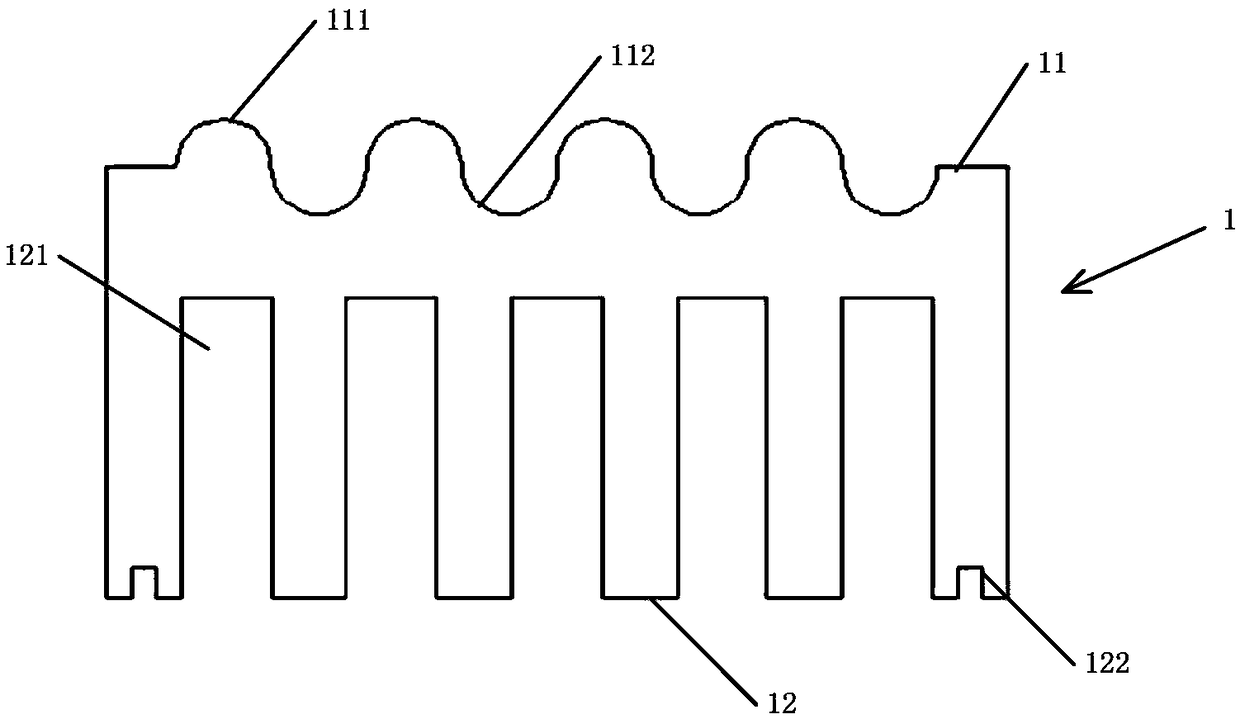

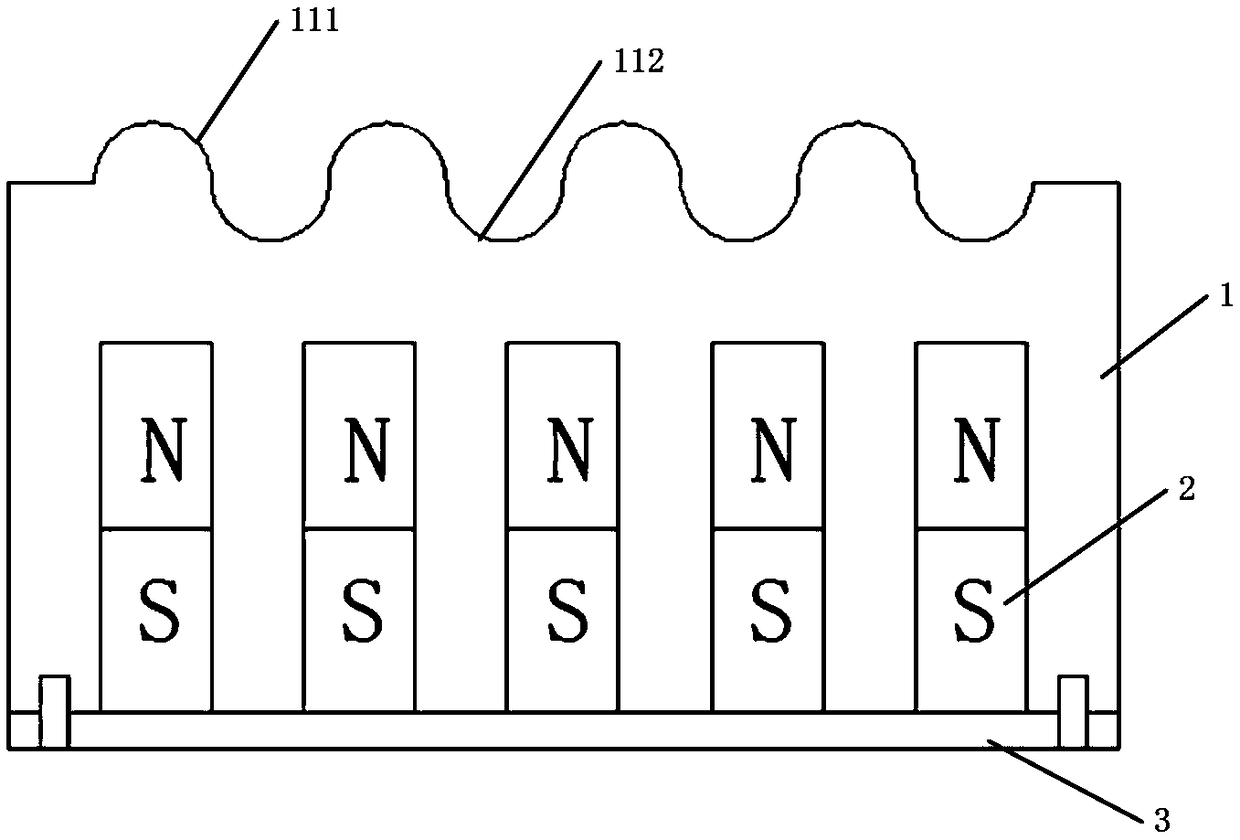

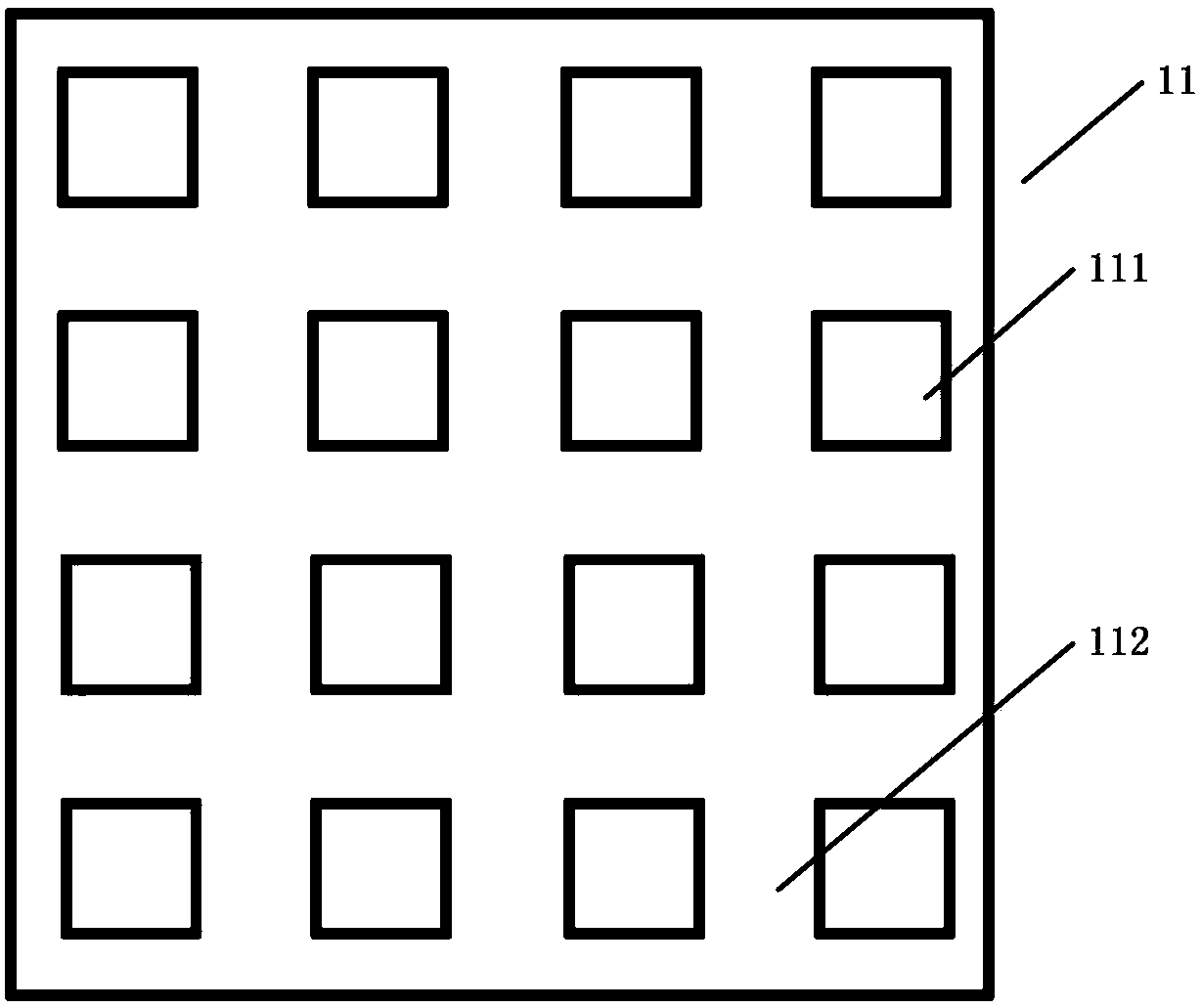

[0027] Such as figure 1 , figure 2 As shown, an anti-seating board includes: a board body 1 ; a plurality of magnets 2 ; and a rear cover 3 . The plate body 1 includes an anti-anti-surface 11 and a back surface 12 opposite to the anti-anti-surface 11 . Several protrusions 111 and grooves 112 are disposed around each protrusion 111 on the anti-impact surface 11 of the board body 1 . The back surface 12 of the board body 1 is provided with a plurality of installation grooves 121 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com