Air atomization air cover for spray gun

A technology of atomizing air and air, which is applied in the direction of spraying devices, spraying devices, liquid spraying devices, etc., can solve the problem of no improvement in spray flow, achieve the effect of shortening the coating process, improving coating quality, and achieving stable coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

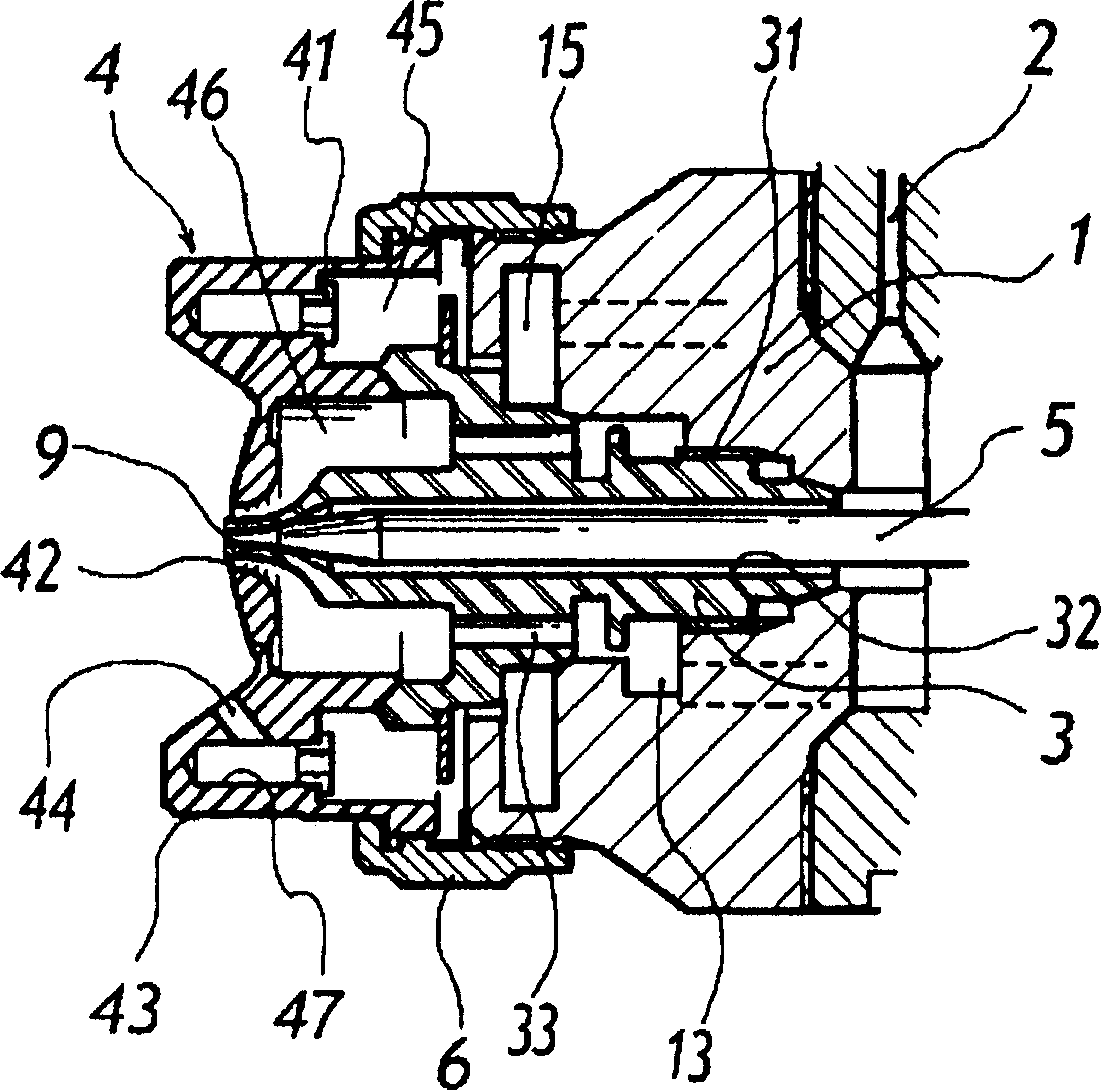

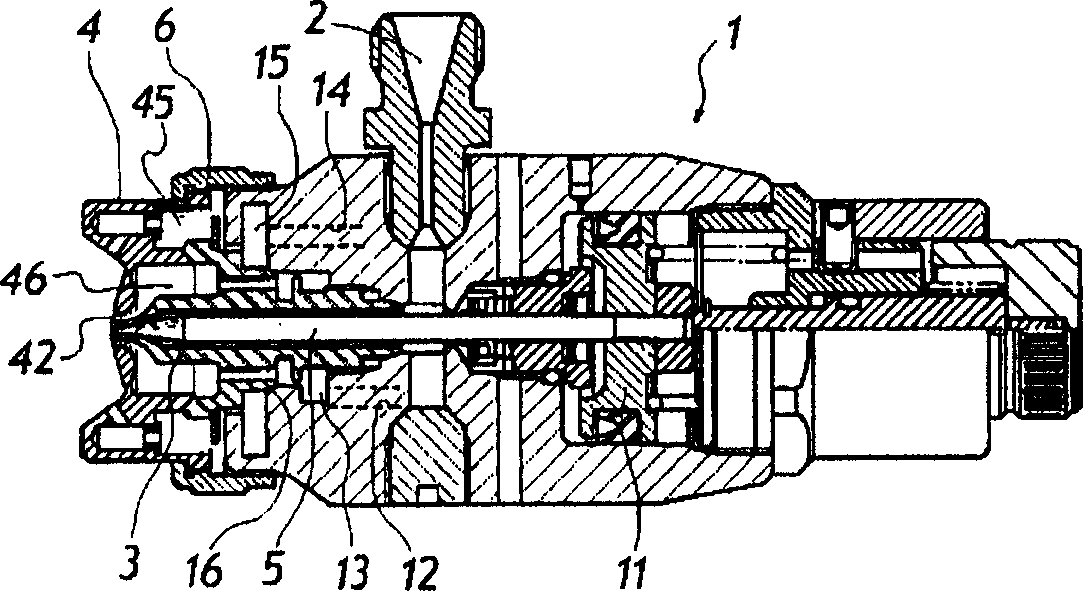

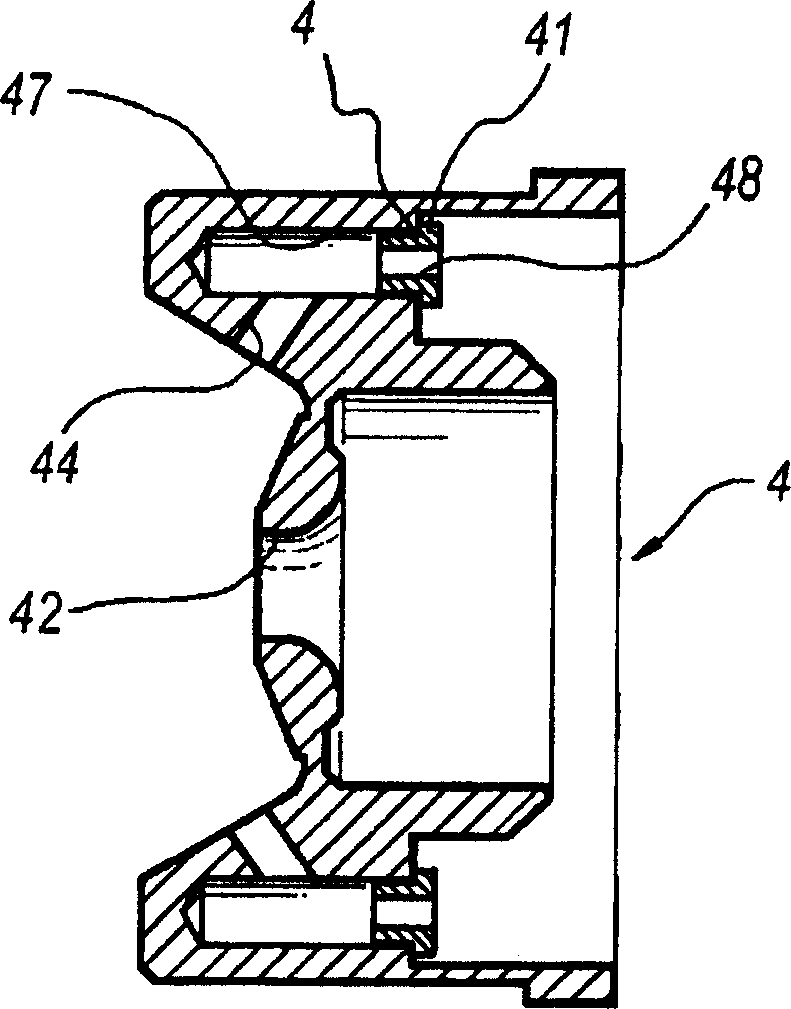

[0052] figure 1 It is a cross-sectional view showing an atomizing air cap and a paint nozzle portion of a spray gun according to an embodiment of the present invention. figure 2 is used figure 1 A cross-sectional view of the overall structure of the air cap spray gun. The spray gun is a so-called automatic spray gun in which the spraying operation is automatically controlled by the action of the working gas, but the atomizing device of the present invention is not limited to these working forms. That is to say, it also applies to hand-operated spray guns with a trigger that are sprayed manually. An atomizing device is provided at the front of the spray gun body 1, an action and adjustment device is provided at the rear, and a paint supply port 2 and an unshown compressed air inlet for spraying are provided at the middle part. The atomizing device at the front end mainly includes: a paint nozzle 3, an air cover 4, and a needle valve 5. The air cover 4 can be freely disassem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com