Comprehensive depositing and coating device and comprehensive coating method

A technology of coating equipment and deposition rate, applied in the field of optical thin films, can solve the problems of reducing film performance, reducing coating efficiency, and increasing coating cost, so as to achieve the effect of improving performance, improving coating efficiency and reducing coating cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

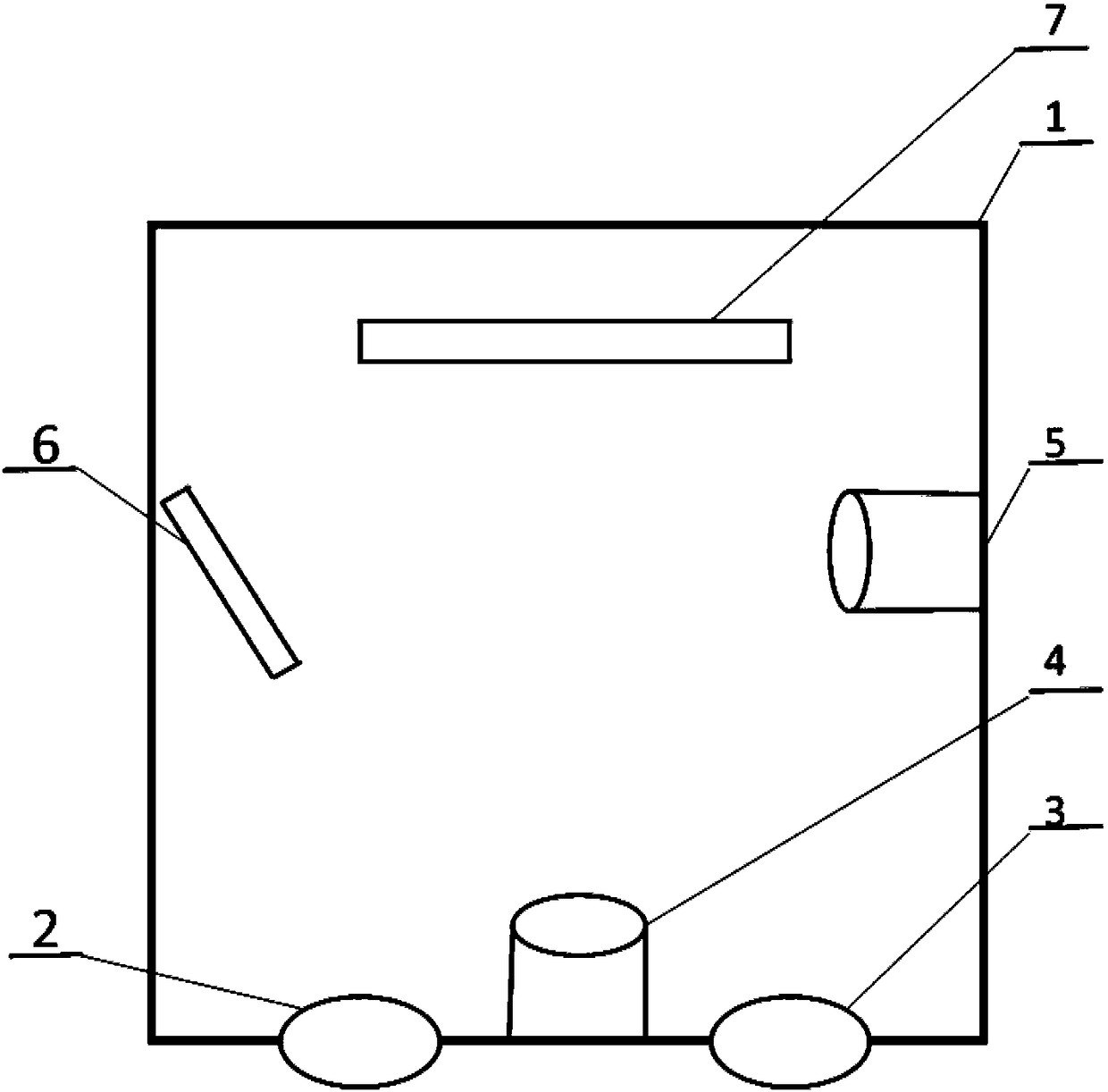

[0025] Please see first figure 1 , figure 1 It is a schematic structural diagram of the electron beam evaporation, ion beam assisted and ion beam sputtering comprehensive deposition and coating equipment of the present invention. It can be seen from the figure that the electron beam evaporation, ion beam assisted and ion beam sputtering comprehensive deposition and coating equipment of the present invention includes a coating machine , the left electron gun crucible 2, the right electron gun crucible 3, the ion auxiliary source 4, the ion main source 5, the sputtering target material 6 and the fixture disc 7 are set in the same vacuum chamber 1, the left electron gun 2 and the right electron gun 3 They are respectively located at the left front part and the right front part of the bottom of the vacuum chamber 1, the ion auxiliary source 4 is located at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com