Preparation method of titanium carbide-based multi-ceramic coating

A ceramic coating and titanium carbide technology, which is applied in the field of preparation of titanium carbide-based multi-component ceramic coatings, can solve the problem of high deposition temperature and achieve the effects of uniform film, high process stability and no residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

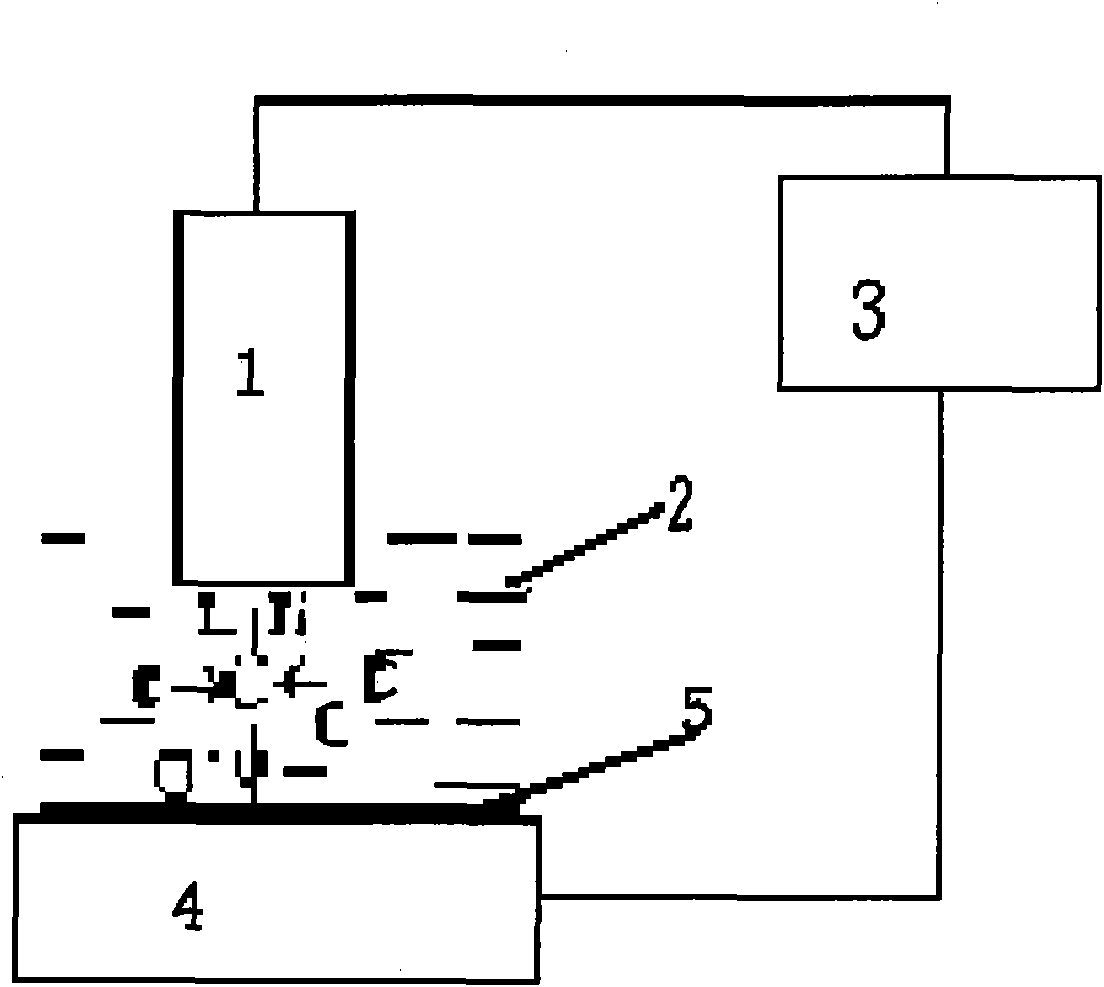

[0030] The principle diagram of the present invention is as figure 1 As shown, the preparation process is carried out on an ordinary EDM machine tool, the liquid medium is industrial aviation kerosene; the discharge electrode is a metal (Ti, W) electrode, and the substrate to be deposited, that is, the workpiece electrode is 45# carbon steel. The deposition area is 80mm 2 , the preparation method of (Ti, W) C ceramic coating of the present invention, comprises the following steps:

[0031] 1) Put the powder sintered block metal electrode (Ti, W) and workpiece electrode into kerosene;

[0032] 2) Connect the anode of the pulse power supply to the powder sintered bulk metal electrode (Ti, W), and connect the cathode of the pulse power supply to the workpiece electrode;

[0033] 3) Turn on the pulse power supply, and the Ti and W metal ions released by the discharge of the powder sintered block metal electrodes (Ti, W) in the liquid medium and the C ions ionized in the kerosene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com