Thickness uniformity control method and chassis adjustment of dlc deposited film

A technology with uniform film thickness and control method, which is applied in the direction of metal material coating process, coating, gaseous chemical plating, etc., can solve the problem of stripping of the lower edge of the workpiece, and achieve uniform peeling, not easy to fall off, and uniform electric field distribution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Such as image 3 As shown, the present invention provides a method for controlling the thickness uniformity of DLC deposition film, which includes the following steps:

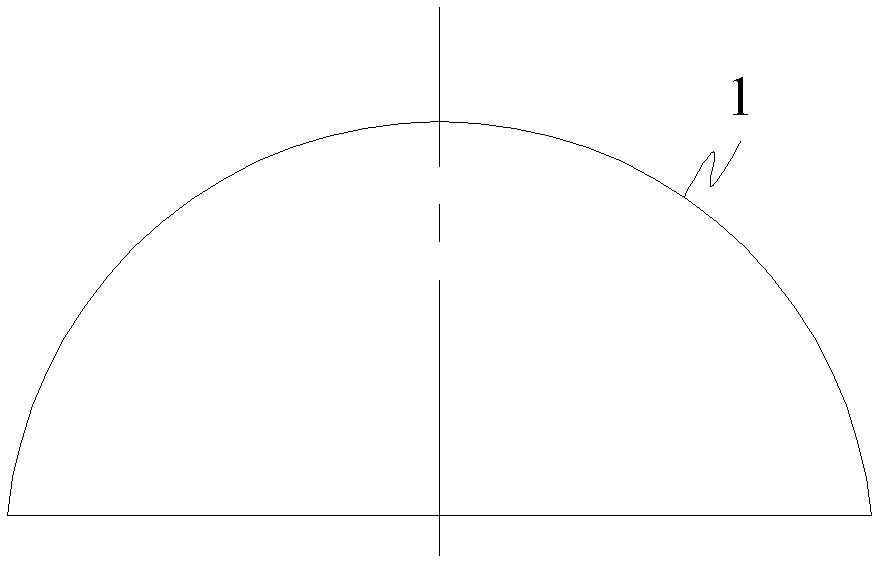

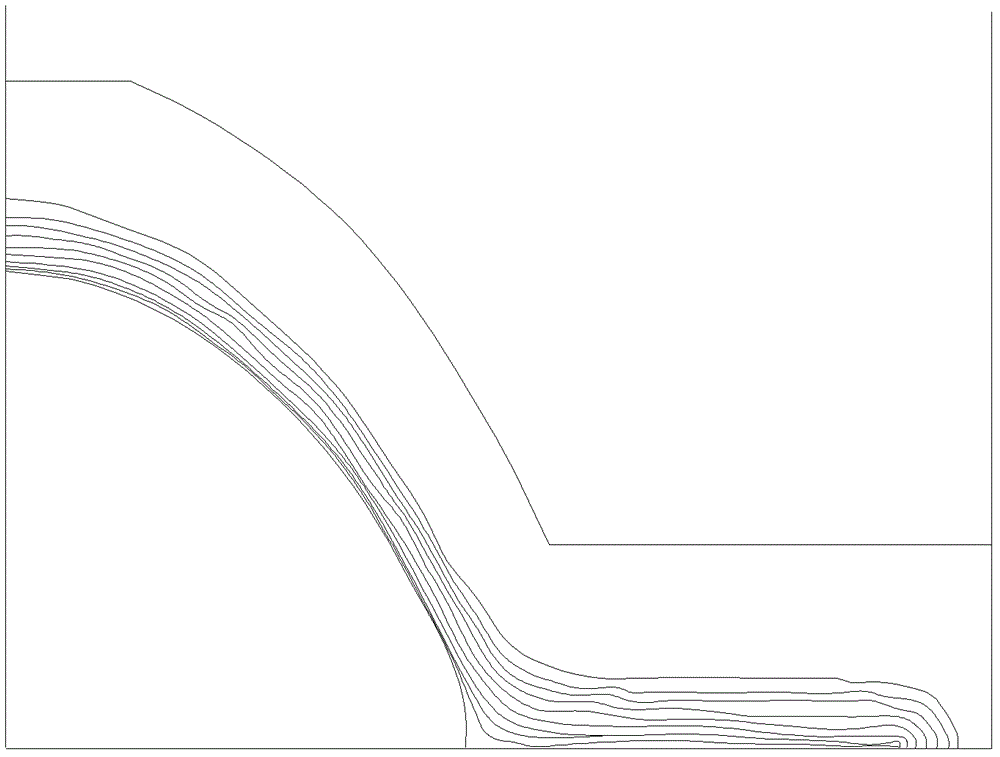

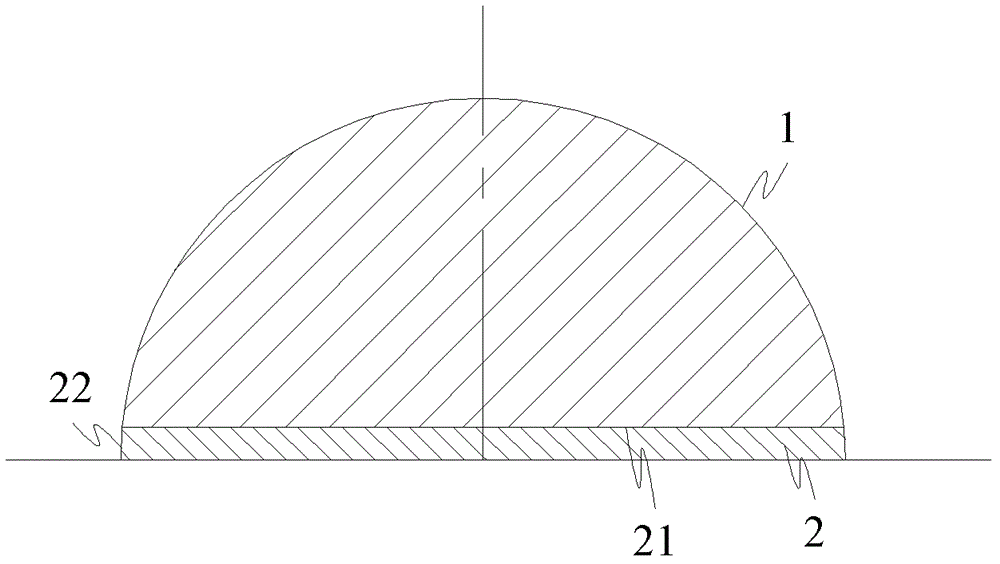

[0024] Step 1. Make an adjustment chassis made of metal material, place the workpiece 1 to be deposited on the adjustment chassis 2, and adapt the workpiece 1 to the adjustment chassis 2, and adjust the exposed peripheral side 22 of the chassis 2 and the workpiece 1 A continuous transition is formed between the surfaces of the deposited film; the adjustment chassis 2 is in the shape of a ball table, and the radius of the upper bottom surface 21 of the adjustment chassis 2 is equal to the radius of the bottom surface of the workpiece 1 to be deposited;

[0025] Step 2. Place the workpiece and the adjustment chassis in a vacuum electric field environment;

[0026] Step 3, deposit a DLC film on the surface of the workpiece 1 to be deposited and the exposed peripheral side surface 22 of the adjustment chassis 2;

...

Embodiment 2

[0032] Such as Image 6 As shown, this embodiment provides a method for controlling the uniformity of film thickness of the DLC film deposition adjustment chassis 2. The adjustment chassis 2 is made of metal, and the adjustment chassis 2 is used to interact with the workpiece to be deposited on it. 1 is adapted and adjusted to form a continuous transition between the exposed peripheral side 22 of the chassis 2 and the surface of the workpiece 1 to be deposited. The adjusting base plate 2 corresponds to different shapes of the workpiece to be deposited, and can be set in the shape of a ball table, a truncated cone, a truncated cone, a cylindrical shape or a prismatic shape. In order to make the adjustment chassis 2 and the workpiece 1 to be deposited more accurately, ensure that the exposed peripheral side 22 of the adjustment chassis 2 extends downward along the lower edge of the workpiece 1 to be deposited and presents a continuous surface. A positioning shaft or positioning h...

Embodiment 3

[0035] Such as Figure 7 As shown, the adjusting chassis is composed of a metal ring 4 and a base frame 3 arranged in the metal ring 4; the inner peripheral side 42 of the metal ring 4 matches the outer wall 31 of the base frame 3, and the metal ring 4 The outer peripheral side surface 41 of φ can form a continuous transition with the surface of the workpiece 1 placed thereon to be deposited. In order to make the bottom frame 3 and the metal ring 4 fit more accurately with the workpiece to be deposited, it is ensured that the outer peripheral side 41 of the metal ring 4 extends downward along the lower edge of the surface of the workpiece 1 to be deposited and forms a line. The continuous surface is provided with positioning shafts or positioning holes on the bottom frame 3, Figure 7 Shown in is positioning axis 5. For the workpieces to be deposited with the same size, the bottom frame can be reused. After each deposition on the workpiece, only the metal ring can be replaced...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com