A device for extracting ions in a diamond-like thin film ion source

A technology of diamond film and extraction device, which is applied in metal material coating process, gaseous chemical plating, coating, etc., can solve the problems of difficult adjustment of film uniformity, uneven diffusion of process gas, and decrease of film uniformity, etc., to achieve Achieve film uniformity and deposition rate, achieve adjustment, and improve the effect of molecular density uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

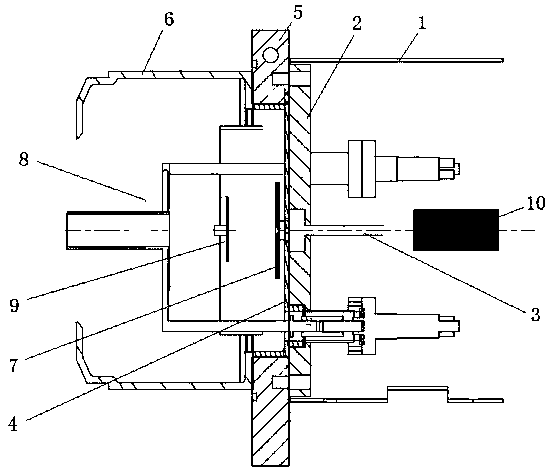

[0024] See attached picture:

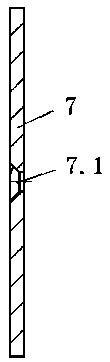

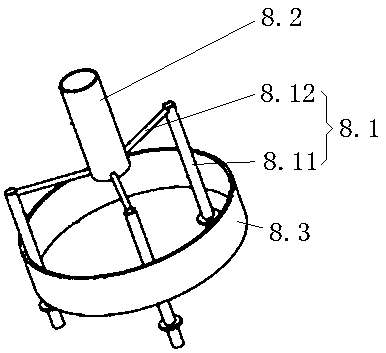

[0025] The ion extraction device in the diamond-like thin film ion source includes a partition 2 installed at the left end of the protective shell 1, a process gas inlet pipe 3 is installed horizontally in the middle of the partition 2, and an internal baffle 4 is installed on the left end of the partition 2. The internal baffle An installation flange 5 is fixed on the partition on the outer periphery of the plate 4, an ion source retaining ring 6 is installed on the installation flange 5, a process gas diffusion plate 7 is installed on the outer side of the inner baffle 4, and the outer periphery of the process gas diffusion plate 7 is provided with a through The anode 8 installed on the inner baffle 4 and the separator, and a tungsten wire 9 is arranged between the anode 8 and the process gas diffusion plate 7 .

[0026] A magnet 10 located at the outlet end of the process gas inlet pipe is arranged in the inner cavity of the protective shell 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com