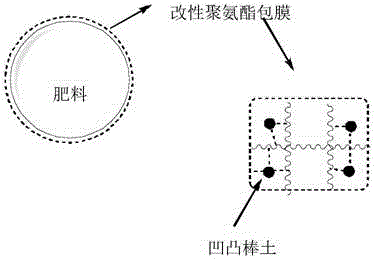

Composite modified polyurethane coating slurry, controlled release fertilizer and preparation method of controlled release fertilizer

A compound modification and controlled-release fertilizer technology, which is applied in the direction of urea compound fertilizer, layered/coated fertilizer, alkaline orthophosphate fertilizer, etc., can solve the problems of difficult degradation of membrane materials, low continuous level, high production cost, etc. , to achieve the effect of facilitating degradation, simple film forming process, and reduced coating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

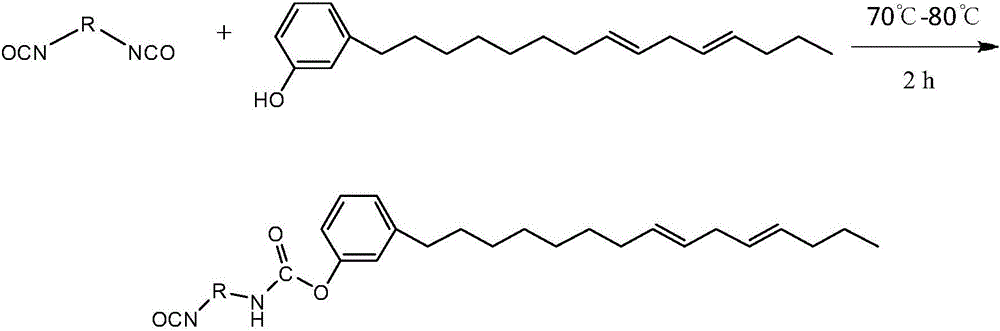

[0027] (1) Weigh 24.50 g of castor oil and 7.00 g of attapulgite in advance, add them into a small beaker and mix them evenly with a magnetic stirrer to obtain component A. (2) Weigh 16.60 g of polymethylene polyphenyl polyisocyanate and 3.80 g of cardanol in advance, heat up to 75° C., and react for 2 hours to obtain polymethylene polyphenyl polyisocyanate modified by cardanol, Obtain the B component. (3) After mixing the above-mentioned components A and B evenly, the vegetable oil-based attapulgite hybrid composite modified polyurethane coating liquid is obtained; (4) Weigh 15-15-15 1000g of compound fertilizer granules are placed in a coating machine, and the coating machine is turned on to preheat the fertilizer granules until the temperature of the fertilizer granules reaches 70°C; (5) the vegetable oil-based attapulgite prepared in step (3) is mixed with Chemical composite modified polyurethane coated slurry spraying on the surface of the 15-15-15 composite fertilizer p...

Embodiment 2

[0030](1) Weigh 18.40 g of castor oil and 5.50 g of attapulgite in advance, add them into a small beaker and mix them evenly with a magnetic stirrer to obtain component A. (2) Weigh 8.10 g of polymethylene polyphenyl polyisocyanate and 1.54 g of cardanol in advance, heat up to 78° C., and react for 2 hours to prepare polymethylene polyphenyl polyisocyanate modified by cardanol, Obtain the B component. (3) After mixing the above-mentioned components A and B evenly, the vegetable oil-based attapulgite hybrid composite modified polyurethane coating liquid is obtained; (4) Weigh 15-15-15 1000g of compound fertilizer granules are placed in a coating machine, and the coating machine is turned on to preheat the fertilizer granules until the temperature of the fertilizer granules reaches 65°C; (5) the vegetable oil-based attapulgite prepared in step (3) is mixed with Chemical composite modified polyurethane coated slurry spraying on the surface of the 15-15-15 composite fertilizer pa...

Embodiment 3

[0033] (1) Weigh 18.40 g of soybean oil and 4.80 g of attapulgite in advance, add them into a small beaker and mix them evenly with a magnetic stirrer to obtain component A. (2) Weigh 8.60 g of polymethylene polyphenyl polyisocyanate and 1.79 g of cardanol in advance, heat up to 80° C., and react for 2 hours to obtain polymethylene polyphenyl polyisocyanate modified by cardanol, Obtain the B component. (3) After mixing the above-mentioned components A and B evenly, the vegetable oil-based attapulgite hybrid composite modified polyurethane coating liquid is obtained; (4) Weigh 15-15-15 1000g of compound fertilizer granules are placed in a coating machine, and the coating machine is turned on to preheat the fertilizer granules until the temperature of the fertilizer granules reaches 70°C; (5) the vegetable oil-based attapulgite prepared in step (3) is mixed with Chemical composite modified polyurethane coated slurry spraying on the surface of the 15-15-15 composite fertilizer p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com