Combined female contact element

A contact and combined technology, applied in the direction of contact parts, etc., can solve the problems of unfavorable connector interface standardization promotion, cost increase, unsatisfactory elastic performance and fatigue resistance of the contact head, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

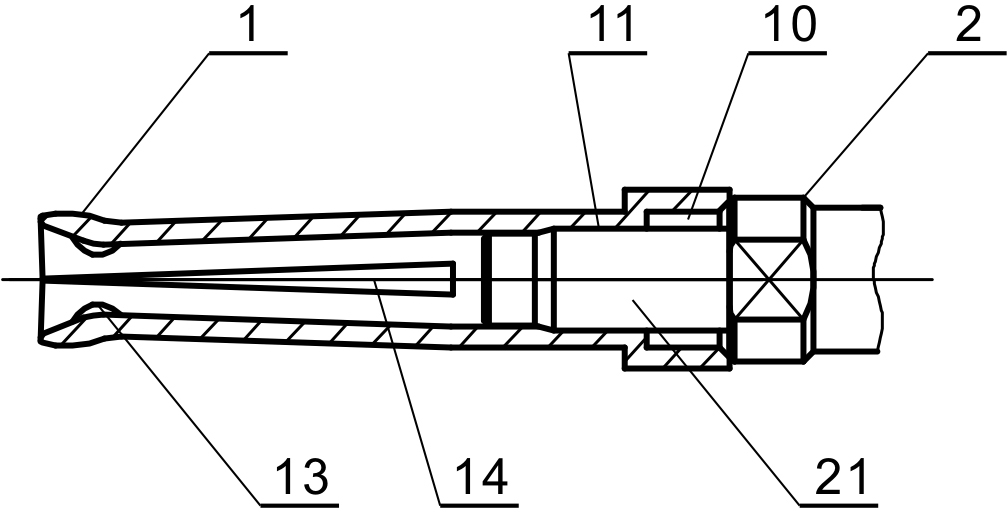

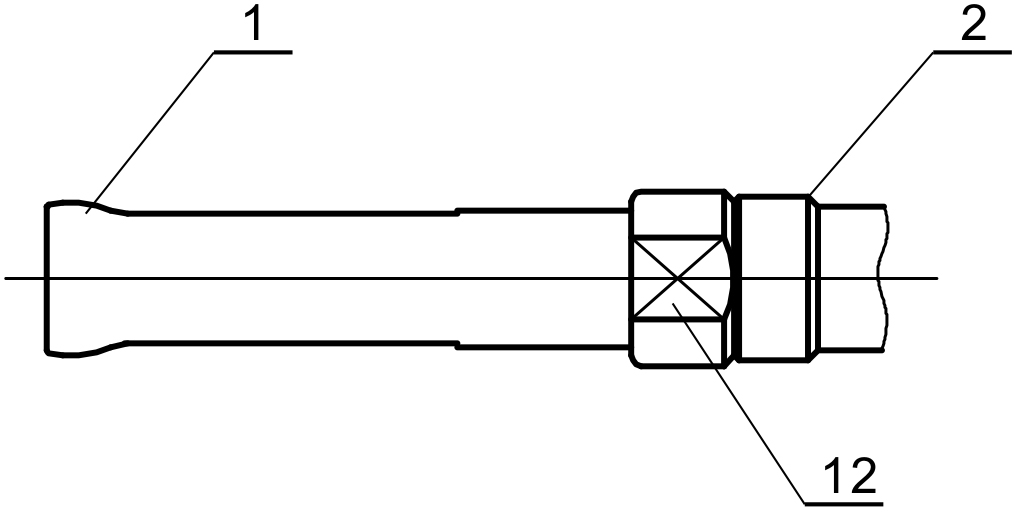

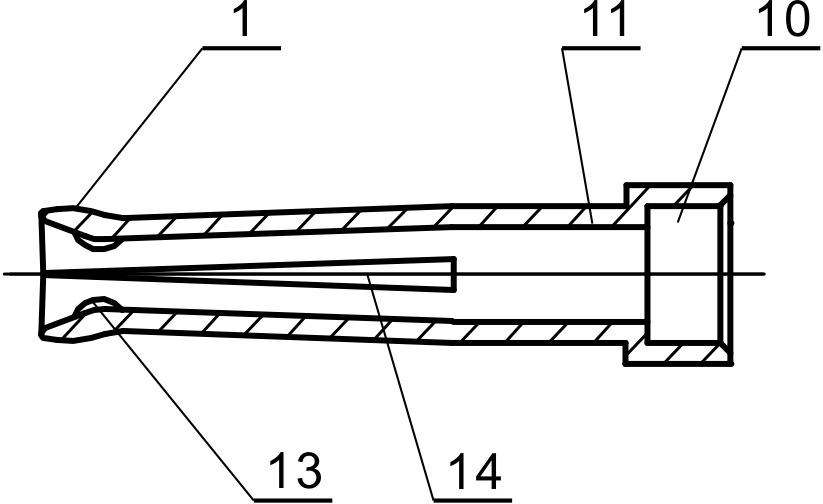

[0012] refer to figure 1 , figure 2 , image 3 , the present invention includes a head 1 and a tail end 2, the head 1 is a cylindrical body, one end of the cylindrical body is provided with a stepped hole 10 and an assembly hole 11 along the inner wall in sequence, and the other end is opened with a symmetrical axis along the wall. Notch 14, the depth of notch 14 is 1 / 2 to 2 / 3 of the total length of the head 1, the inner wall of the cylindrical cylinder of the port is provided with a flange 13, and the cylindrical barrel of the port is forced to deform the notch 14 into a contract The tail end 2 is a rod, one end of which is a cylindrical head 21, and the other end is a connecting head; the cylindrical head 21 of the tail end 2 passes through the step hole 10 of the head 1 and is inserted into the assembly hole 11, and the cylindrical head 21 It is an interference fit with the assembly hole 11 ; the outer wall of the stepped hole 10 of the head 1 is a flat square 12 .

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com