Method for preparing disperse red 60

A technology of disperse red and weight percentage, applied in the direction of amino-hydroxyanthraquinone dyes, etc., can solve the problems of inability to change environmental pollution, low yield, consumption of steam, etc., achieve obvious economic and environmental benefits, and reduce the loss of phenol , the effect of reducing the operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

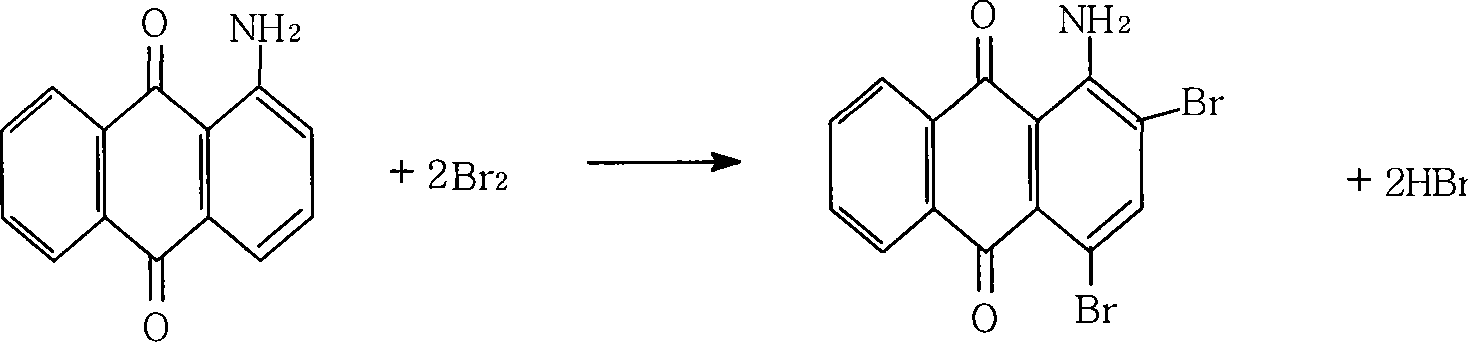

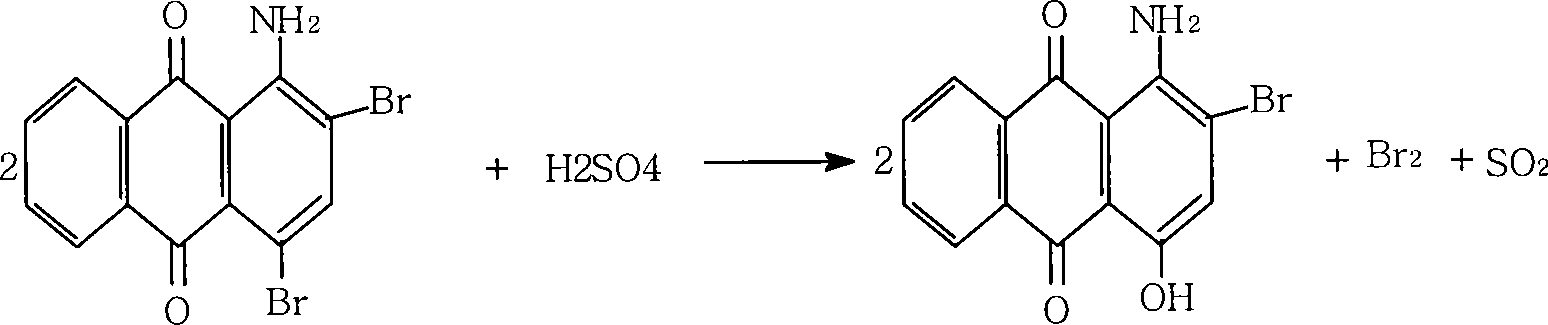

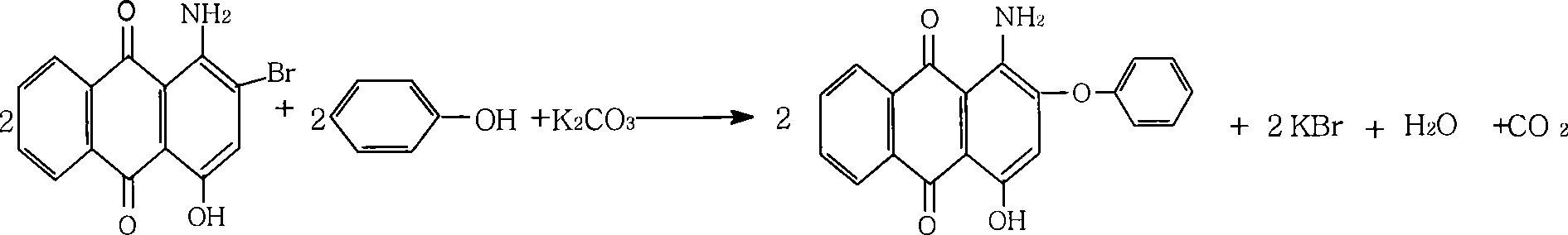

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: the 4M 3 Condensation mother liquid water is poured into a 6300L enamel kettle with a pump, and stirring is started, and 60kg of 98% sulfuric acid and 50kg of sodium sulfate are slowly added. After the addition, stir for half an hour, static layering, the upper layer is a solution containing phenol and disperse red 60 dissolved in phenol, and the lower layer is a potassium bromide solution. Add alkali to the upper layer solution to adjust the pH to 6-9, which is the treated mother liquor water. Add 700kg of mother liquid water prepared above, 300kg of phenol, 500kg of dry product of 1-amino-2-bromo-4-hydroxyanthraquinone and 180kg of acid-binding agent potassium carbonate in a 5000L enamel reaction kettle, and the feeding ends in 2 hours Raise the temperature to 148-150°C, and keep it warm for 5-6 hours. After the detection reaches the end point, cool down to 90-105°C, add 1000kg of 3-5% light alkaline water at this temperature, and finally cool down to 5...

Embodiment 2

[0022] Embodiment 2: the 4M 3 Condensation mother liquid water is pumped into the enamel kettle of 6300L, starts stirring, slowly adds 250kg of 50% waste sulfuric acid and 90kg of sodium chloride, and the following process steps are the same as in Example 1. In the 5000L enamel reaction kettle, add 600kg of the above-mentioned treated mother liquor water, 400kg of phenol, 500kg of dry product of 1-amino-2-bromo-4-hydroxyanthraquinone and 180kg of acid-binding agent potassium carbonate, and implement the following process steps example 1. Promptly get disperse red 60% dry 513kg, yield rate is 98.6%, content is 99.7%. The unit consumption of phenol per ton of Disperse Red 60 is 477kg.

Embodiment 3

[0023] Embodiment 3: the 4M 3 Condensation mother liquor water is pumped into the enamel kettle of 6300L, starts to stir, slowly adds 25% sulfuric acid 240kg and sodium sulfate 200kg, following process steps are the same as embodiment 1. In the 5000L enamel reaction kettle, add 900kg of the above-mentioned treated mother liquor water, 200kg of phenol, 500kg of dry product of 1-amino-2-bromo-4-hydroxyanthraquinone and 180kg of acid-binding agent potassium carbonate, and implement the following process steps example 1. Promptly get disperse red 60% dry 518kg, yield rate is 99.5%, content is 99.2%. The unit consumption of phenol per ton of Disperse Red 60 is 410kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com