Waterborne polyurethane-acrylic emulsion as well as preparation method and application thereof

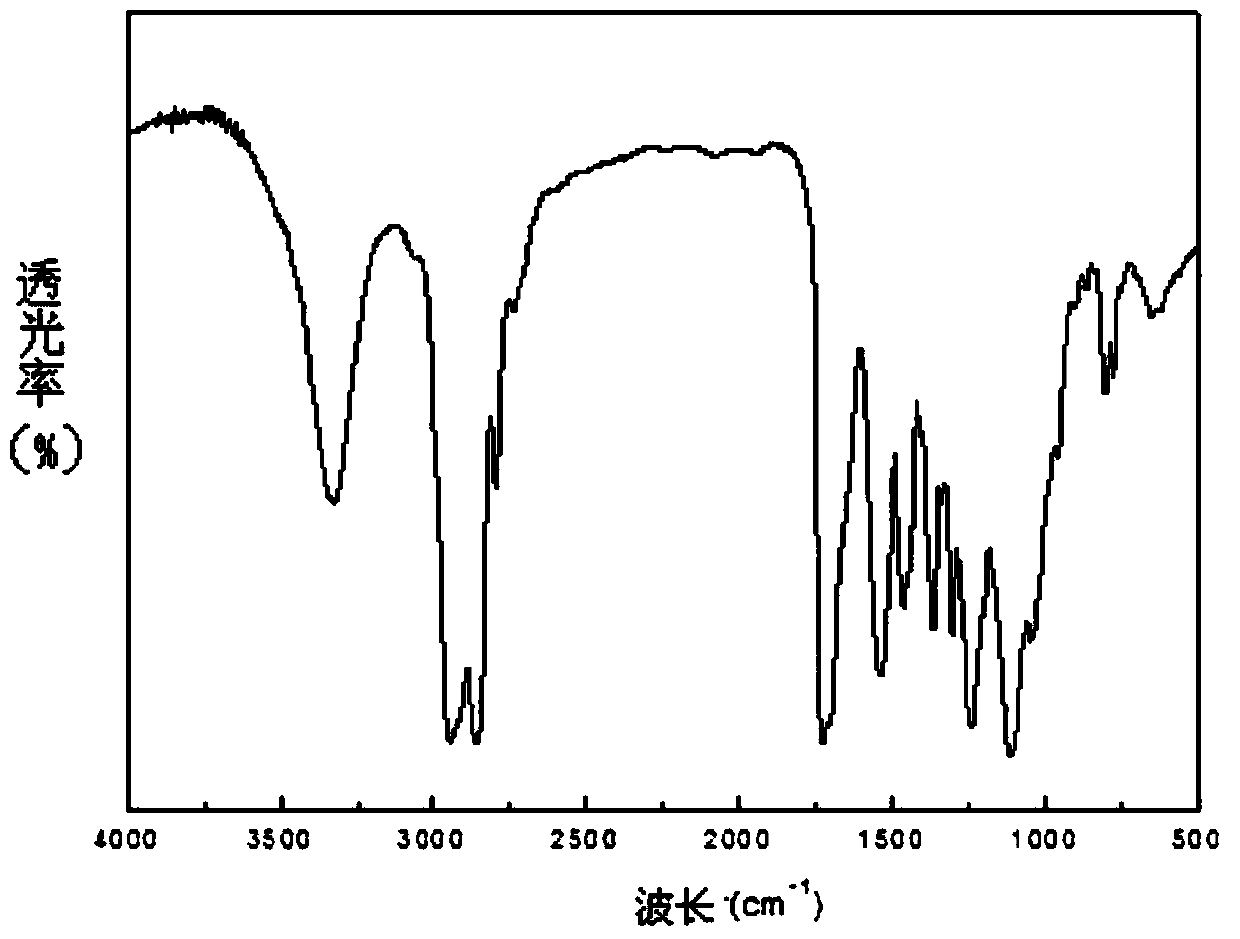

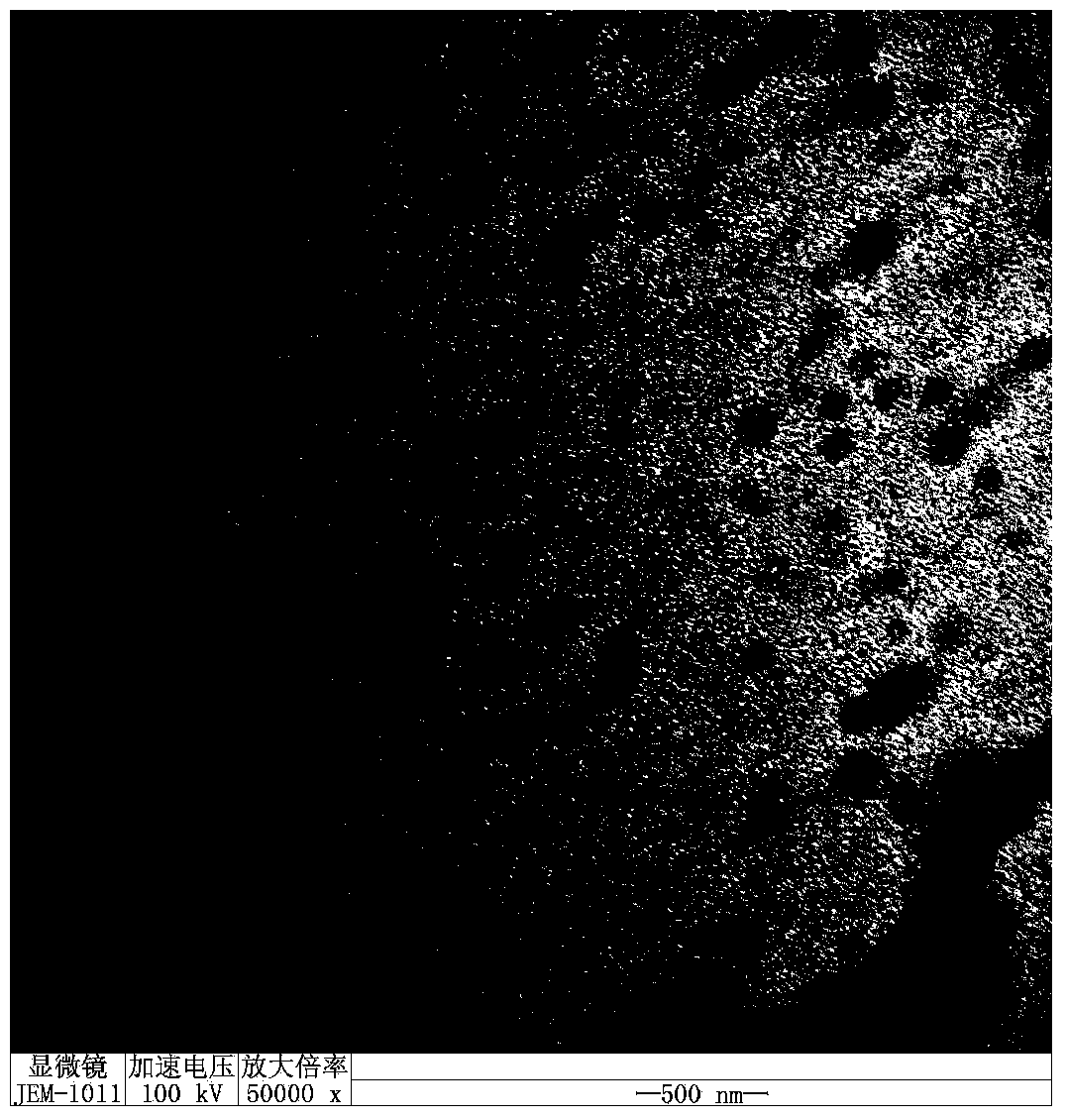

A water-based polyurethane and acrylic emulsion technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of easy phase separation, high cost, poor water resistance of polyurethane, etc., to improve surface properties and film-forming properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

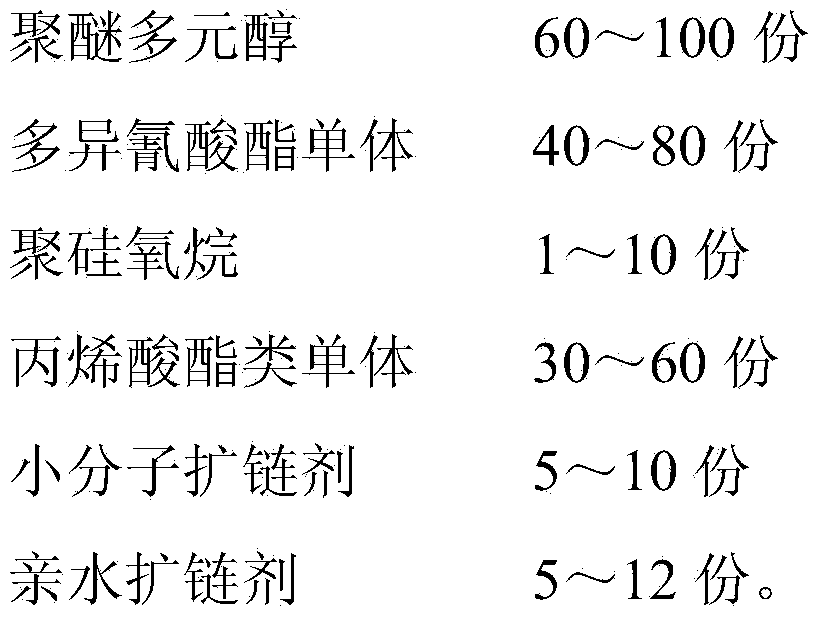

[0034] The present invention also provides a kind of preparation method of aqueous polyurethane-acrylic acid emulsion, comprises as follows:

[0035] Step 1: Add polyether polyol, polyisocyanate monomer, polysiloxane, hydrophilic chain extender, small molecule chain extender and catalyst into the reaction vessel, and react at 75-85°C for 4-6 hours to obtain prepolymer;

[0036] Step 2: Lower the temperature in the reaction vessel to 55-65°C, then add a part of acrylate monomer, lower the temperature to 30-45°C, add neutralizer, react for 5-10 minutes, add deionized Stir with water to obtain polyurethane emulsion;

[0037] Step 3: adding an initiator, an emulsifier and the remaining acrylic ester monomers into a reaction vessel, and reacting at 70-85° C. for 2-6 hours to obtain a water-based polyurethane-acrylic acid emulsion.

[0038] In step 1 of the present invention, after adding polyether polyol into the reaction vessel, vacuum dehydration is preferably carried out at 11...

Embodiment 1

[0046] Add 100 g of polytetrahydrofuran diol (data molecular weight: 4000) into a three-necked flask equipped with a stirring device, a condenser, and a thermometer, vacuumize and dehydrate at a temperature of 120°C for 1 hour, and then add a hydrophilic chain extender, dimethylol Propionic acid 12g, chain extender 1,4-butanediol 10g, hydroxyl-terminated polydimethylsiloxane (data molecular weight: 2000) 10g and catalyst dibutyltin dilaurate 0.1g, under the protection of dry nitrogen, The temperature is controlled at 85°C, and after the above mixed solution is melted, 80 g of isophorone diisocyanate is added at one time, and reacted for 4 hours until the -NCO value reaches the theoretical value to obtain a prepolymer;

[0047] Lower the temperature in the three-necked flask to 60°C, then add 30g of methyl methacrylate and butyl acrylate mixture for dilution (mass ratio is 1:1), lower the temperature to 40°C, add 4g of triethylamine, react for 5min, Add deionized water at room ...

Embodiment 2

[0052] Add 60g of polyoxyethylene glycol (data molecular weight: 1000) into a three-necked flask equipped with a stirring device, a condenser, and a thermometer, vacuumize and dehydrate at a temperature of 120°C for 1 hour, and then add a hydrophilic chain extender dihydroxy Methylbutyric acid 5g, chain extender neopentyl glycol 5g, hydroxyl-terminated polydimethylsiloxane (data molecular weight: 500) 1g and catalyst dimethylethanolamine 0.01g, under the protection of dry nitrogen, the temperature is controlled at 75°C, after the above mixture is melted, add 40 g of hexacyclohexyl dicyanate at one time, react for 6 hours until the -NCO value reaches the theoretical value, and obtain a prepolymer;

[0053] Lower the temperature in the three-necked flask to 55°C, then add 15g of ethyl methacrylate, lower the temperature to 30°C, add 5g of tripropylamine to neutralize and form a salt, react for 10min, add deionized water at room temperature, Stir and disperse under the rotating s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com