Metal diaphragm stamping process

A metal diaphragm and process technology, applied in the direction of metal material coating process, manufacturing tools, coatings, etc., can solve the problems of scratches and fractures in the stamping process of metal diaphragms, and the surface is prone to corrosion, so as to improve product quality and ensure Product quality, the effect of ensuring product qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

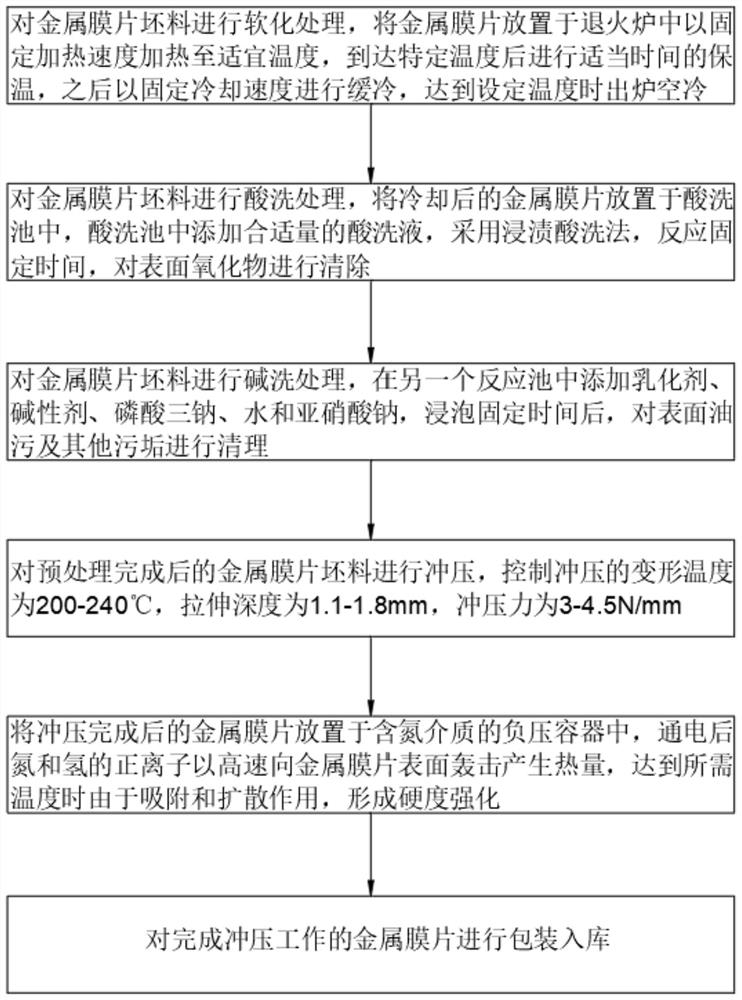

[0025] A metal diaphragm stamping process, comprising the following steps:

[0026] Step 1: Soften the metal diaphragm blank, place the metal diaphragm in an annealing furnace and heat it to 450 °C at a heating rate of 90 °C / h, and add annealing oil to accelerate heat conduction. The holding time is 4 hours. Slow cooling at a cooling rate of 20°C / h, and air cooling when cooled to 200°C;

[0027] Step 2: Pickling the metal diaphragm blank, placing the cooled metal diaphragm in the pickling tank, adding pickling liquid to the pickling tank, adopting the dipping pickling method, reacting for 45 minutes, and removing the surface oxide clear;

[0028] Step 3: Alkaline cleaning of the metal diaphragm blank, adding 2 parts of emulsifier, 15 parts of alkaline agent, 2 parts of trisodium phosphate, 100 parts of water and 6 parts of sodium nitrite in another reaction tank, after soaking for 45 minutes , to clean the surface oil and other dirt;

[0029] Step 4: Stamp the metal diaphra...

Embodiment 2

[0038] A metal diaphragm stamping process, comprising the following steps:

[0039] Step 1: Soften the metal diaphragm blank, place the metal diaphragm in an annealing furnace and heat it to 550 °C at a heating rate of 100 °C / h, and add annealing oil to accelerate heat conduction at the same time. The holding time is 3 hours. Slow cooling at a cooling rate of 30°C / h, and air cooling when cooled to 220°C;

[0040] Step 2: Pickling the metal diaphragm blank, placing the cooled metal diaphragm in the pickling pool, adding pickling liquid to the pickling pool, using the dipping pickling method, reacting for 40 minutes, and removing the surface oxide. clear;

[0041] Step 3: Alkaline cleaning of the metal diaphragm blank, adding 4 parts of emulsifier, 25 parts of alkaline agent, 3 parts of trisodium phosphate, 90 parts of water and 8 parts of sodium nitrite in another reaction tank, soaked for 35 minutes , to clean the surface oil and other dirt;

[0042] Step 4: Stamp the metal...

Embodiment 3

[0051] A metal diaphragm stamping process, comprising the following steps:

[0052] Step 1: Soften the metal diaphragm blank, place the metal diaphragm in an annealing furnace and heat it to 650 °C at a heating rate of 110 °C / h, and add annealing oil to accelerate heat conduction. The holding time is 2 hours. Slow cooling at a cooling rate of 50°C / h, and air cooling when cooled to 240°C;

[0053] Step 2: Pickling the metal diaphragm blank, placing the cooled metal diaphragm in the pickling pool, adding pickling solution to the pickling pool, using the dipping pickling method, reacting for 30 minutes, and removing the surface oxide. clear;

[0054] Step 3: Alkali washing treatment of metal diaphragm blank, add 6 parts of emulsifier, 35 parts of alkaline agent, 5 parts of trisodium phosphate, 80 parts of water and 10 parts of sodium nitrite in another reaction tank, soak for 30 minutes , to clean the surface oil and other dirt;

[0055] Step 4: Stamp the metal diaphragm blank...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Stress | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com