Assembly inspection integrated assembling line based on flexible connection

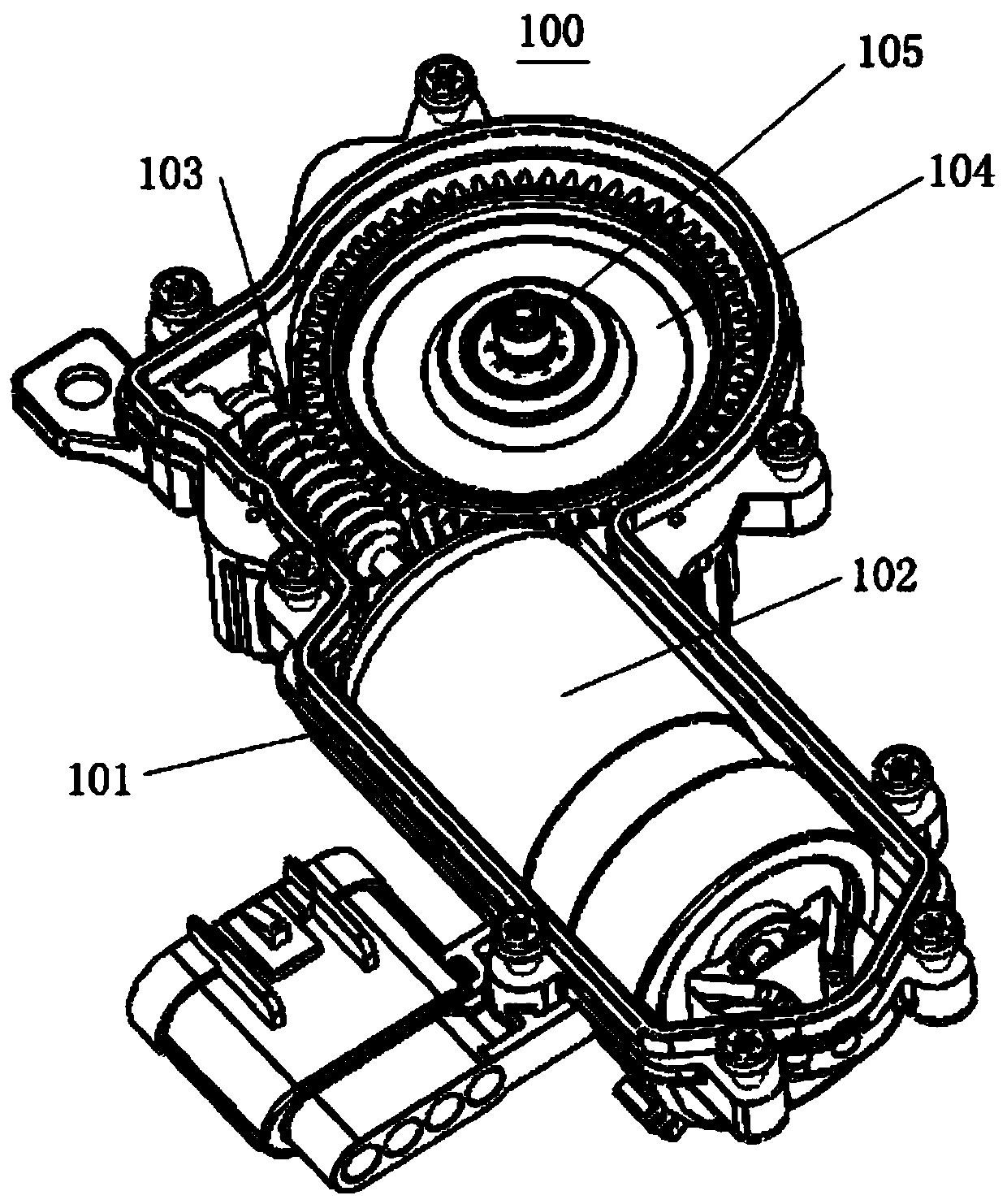

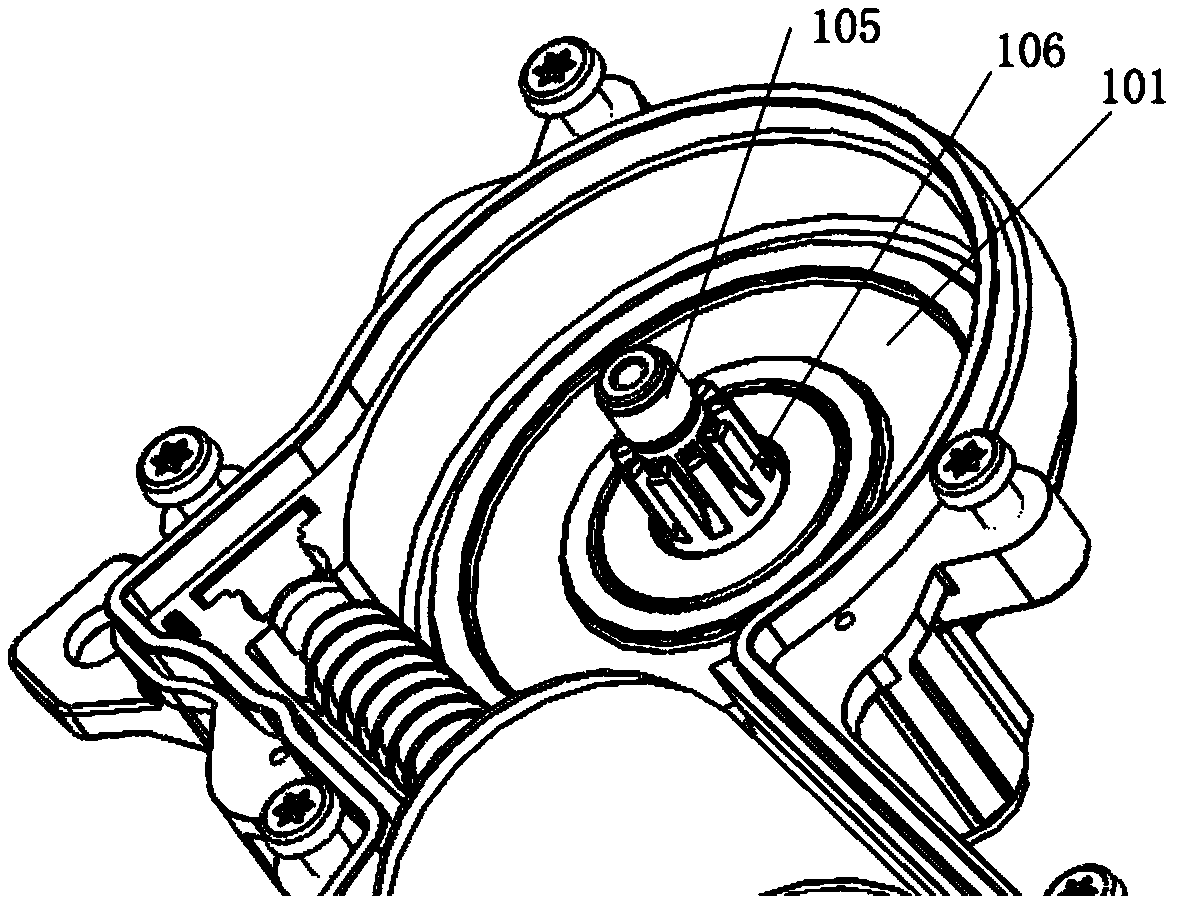

An assembly line and flexible connection technology, applied in the direction of assembly machines, electromechanical devices, electric components, etc., can solve the problems of easily damaged tapered inner ring teeth 105, occupation of human resources, and unqualified products, so as to facilitate efficient production and guarantee Assembly efficiency, the effect of reducing labor occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

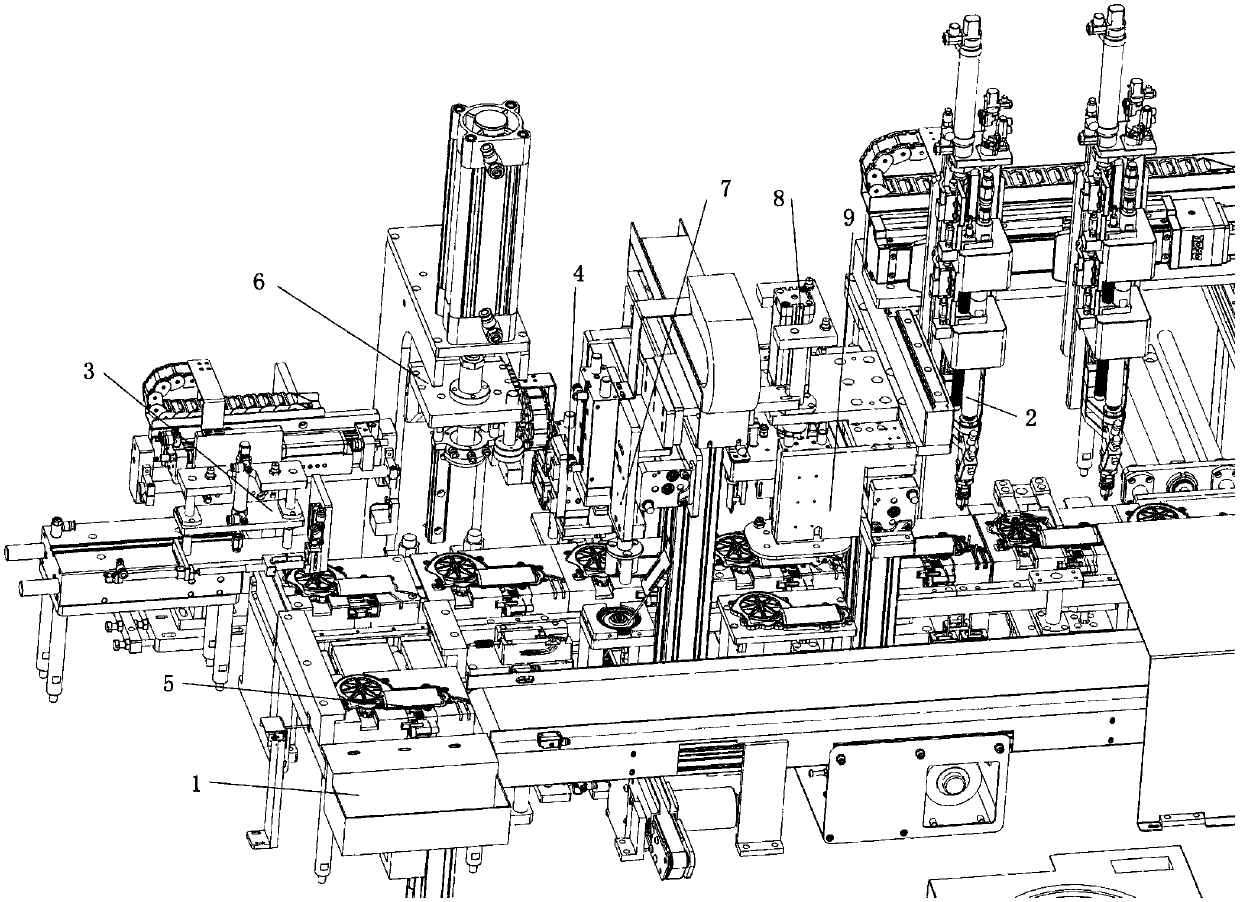

[0029] see Figure 3 to Figure 10 , this embodiment shows an assembly and inspection integrated assembly production line based on flexible connection, including a circular carrier conveying line 1, a carrier 5 arranged on the circular carrier conveying line 1, and sequentially arranged on the circular carrier conveying line Bottom cover loading assembly mechanism, gasket loading assembly mechanism 3, bushing loading assembly mechanism 4, electric motor loading assembly mechanism, pinion loading assembly mechanism 6, large gear loading assembly mechanism on line 1 and used in conjunction with each other Material detection mechanism 7, oil injection detection mechanism 8, upper cover loading assembly mechanism 9, and fixing mechanism 2;

[0030] The circulating carrier conveying line 1 includes a set of conveying line bodies 11 correspondingly arranged, connecting channels 12 correspondingly arranged at both ends of a set of conveying line bodies, and the connecting channel 12 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com