Bush feeding and end cover discharging device for cross-flow end covers

A technology of feeding device and end cover, applied in the directions of transportation and packaging, loading/unloading, conveyor, etc., can solve the problems of not being able to effectively align the top of the cloth, and not being able to feed the cloth, saving manpower and ensuring The effect of product qualification rate and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

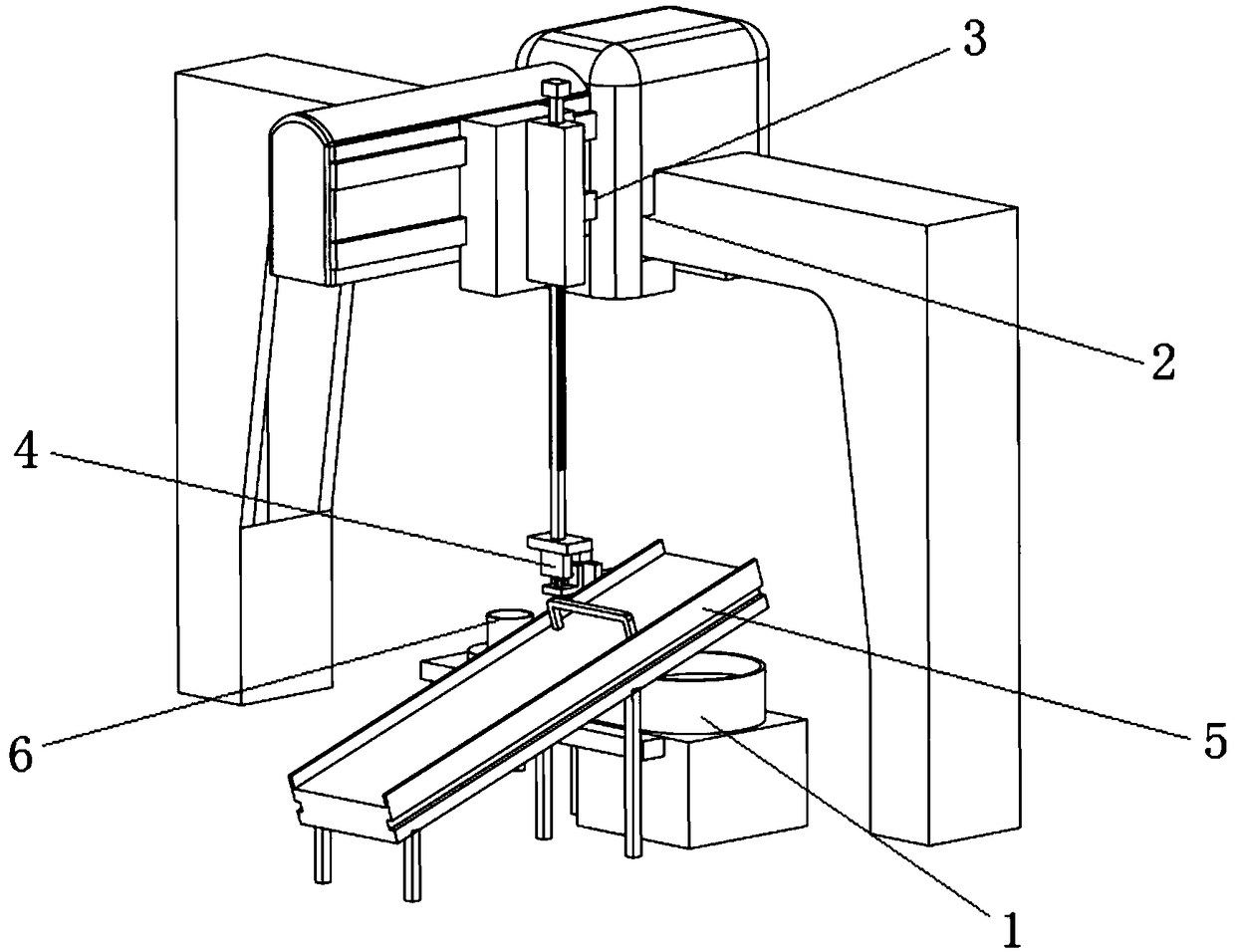

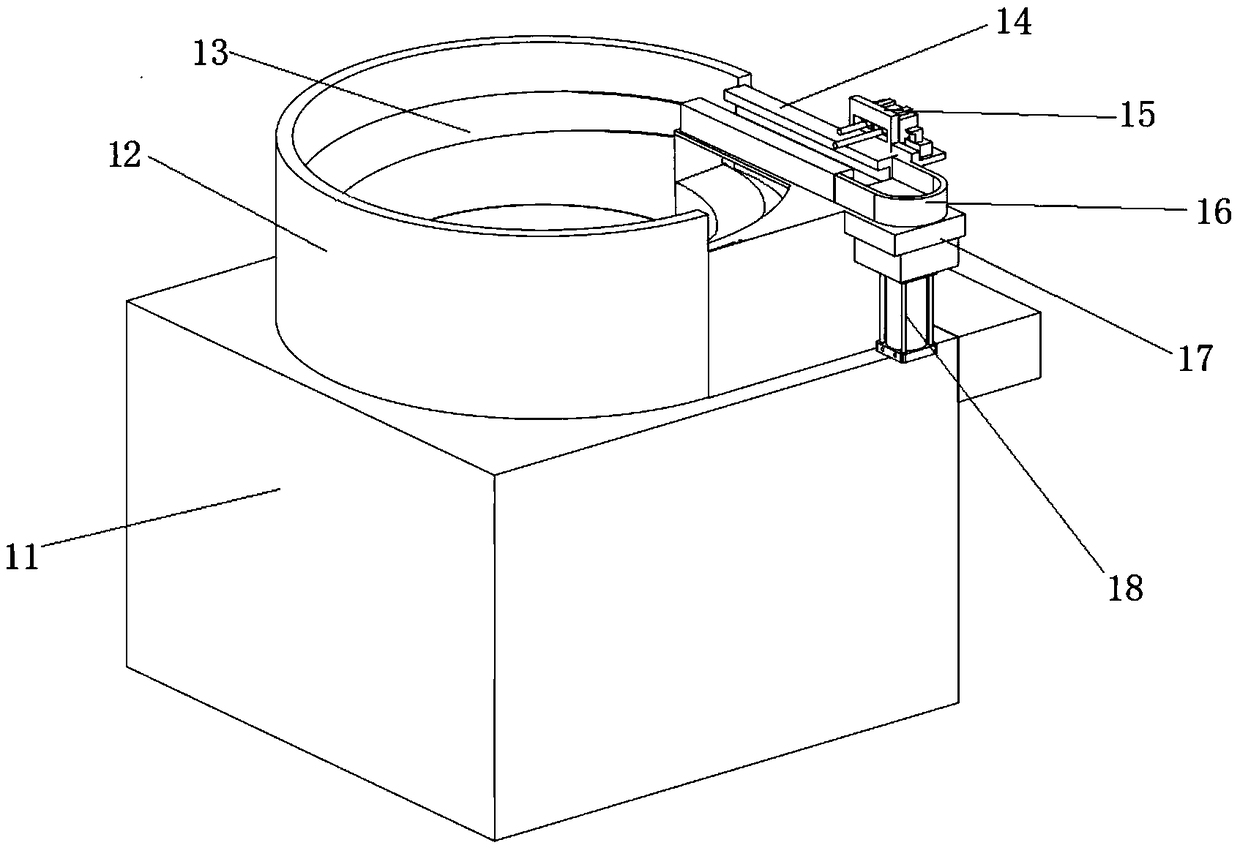

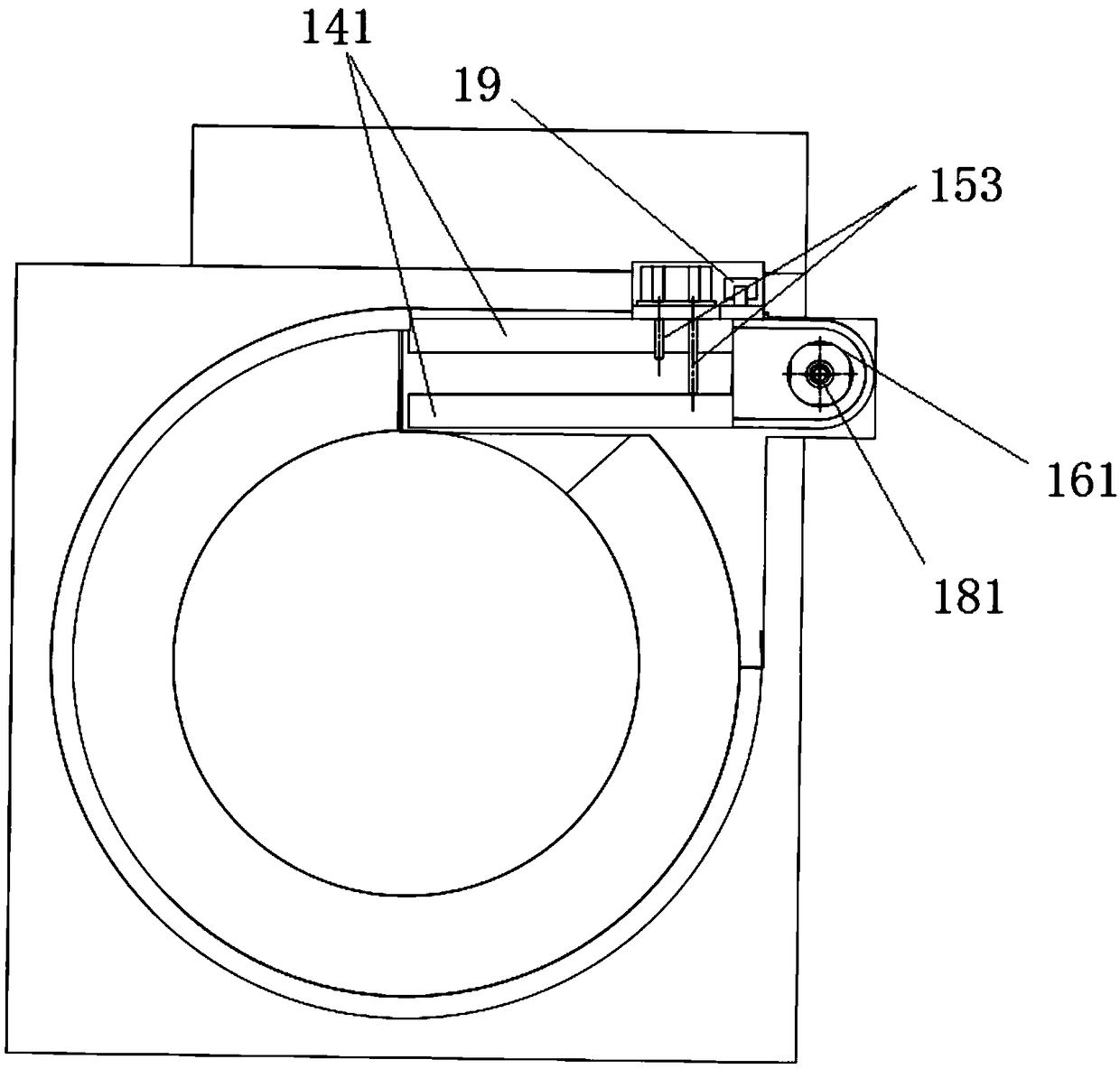

[0023] like Figure 1-6 As shown, the present invention provides a cloth loading and unloading device for through-flow end caps. The loading and unloading device using a loading and unloading manipulator also includes a slideway 5, a loading and unloading manipulator and a cooling and placing tool 6. The through-flow end cover is composed of metal cloth and injection molded end cover fan. Now, the processed cloth is usually put into the injection mold and then injected into the two parts through insert injection molding without assembly. The openings for loading the cloth and taking out the end caps of the injection molding equipment are lateral openings, and the cloth feeding device 1 and the cooling and placing tool 6 corresponding to the loading and unloading mechanism require the cloth and the end caps to be laid flat.

[0024] The cooling and placing tool 6 includes two cylindrical support cylinders adapted to the mouth of the through-flow end cover, and the cylindrical s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com