Double oil chain, composite slow-cracking and fast-setting asphalt emulsifier and its preparation method and application

An asphalt emulsifier, slow cracking and fast setting technology, applied in chemical instruments and methods, preparation of organic compounds, carboxylic acid amide preparation, etc., to achieve the effects of improving stability, uniform and fine emulsion, and reducing demulsification speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Preparation of emulsifier: Put 67.97g (0.1mol) of OP-10 (nonylphenol polyoxyethylene ether-10) and 0.1mL of concentrated sulfuric acid (95-98% by mass) into a three-necked flask, start stirring, and raise the temperature to 80 Keep the ℃ constant, then slowly add 12.91g (0.14mol) of epichlorohydrin dropwise, the dropwise addition is completed in half an hour, continue to react for 12 hours after the dropwise addition, and evaporate the remaining epichlorohydrin to obtain intermediate a;

[0030] Add 18.90 g (0.1 mol) of tetraethylenepentamine to intermediate a, raise the temperature to 90° C., and stir at this temperature for 6 hours to obtain intermediate b;

[0031] Add 25.12g (0.1mol) of soybean acid into intermediate b, raise the temperature to 150°C, and stir and react at this temperature for 5 hours to obtain a double oil chain, composite slow-cracking and fast-setting asphalt emulsifier.

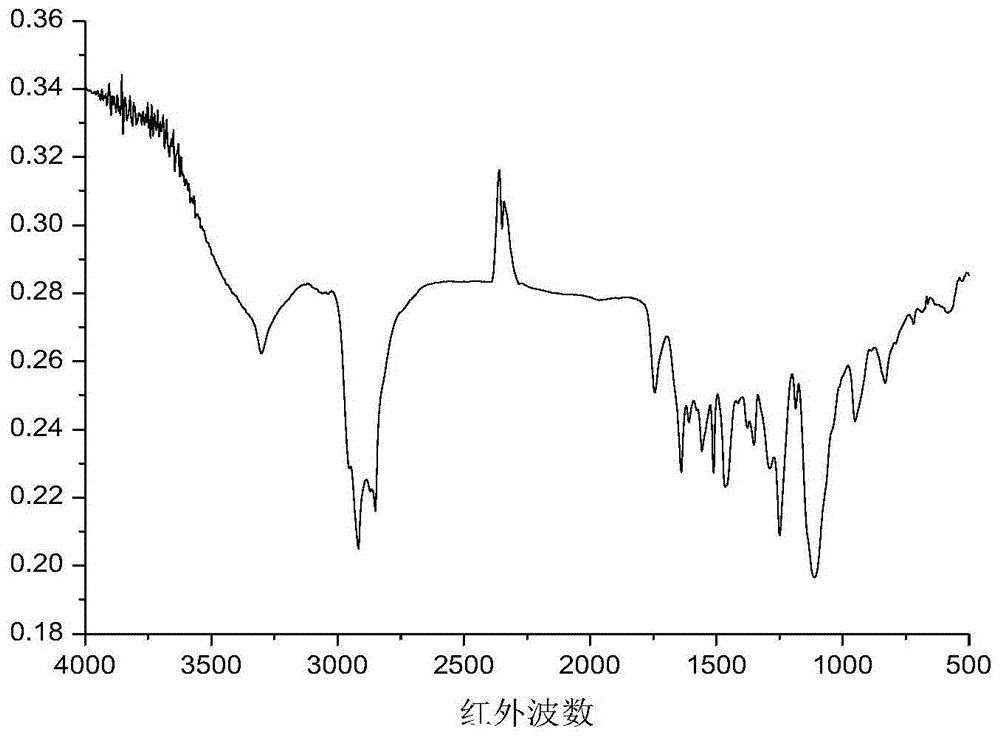

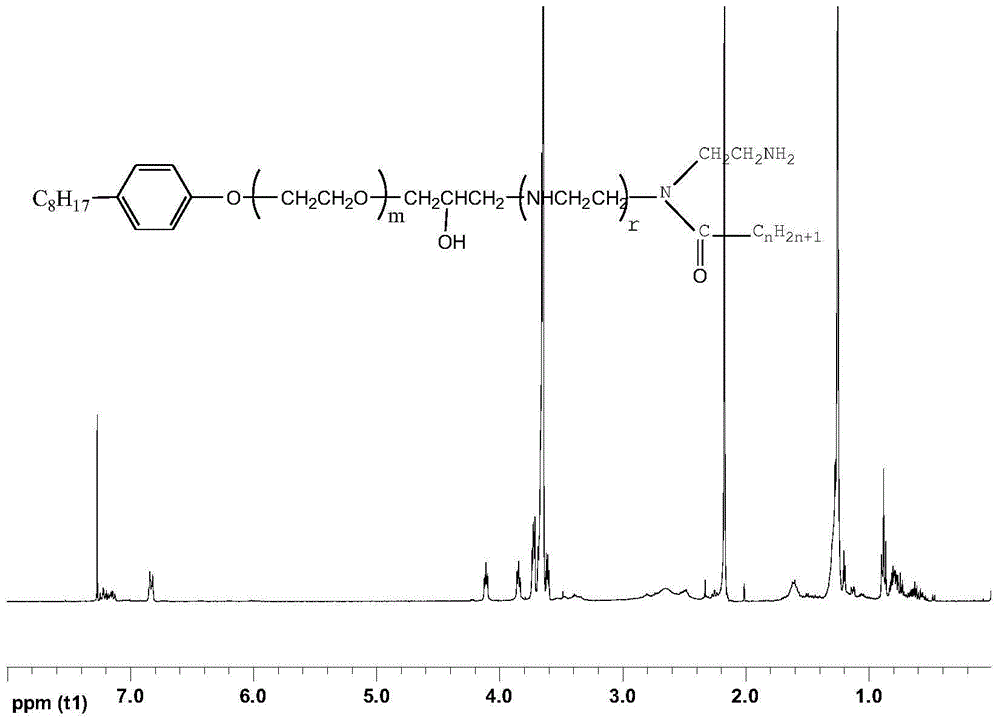

[0032] Carry out preliminary detection of infrared spectrum to this pure p...

Embodiment 2

[0041] Preparation of emulsifier: Change 67.97g (0.1mol) OP-10 to 83.60g (0.1mol) OP-15, and refer to Example 1 for the remaining steps. The target emulsifier was obtained. Among them, m=15, r=4, n=16

[0042] Preparation of aqueous emulsifier solution: Example 1 was repeated.

[0043] Preparation of asphalt emulsion: Preheat the colloid mill with warm water at 80-90°C, add the above-mentioned emulsifier aqueous solution into the colloid mill, then quickly add 100g of hot asphalt at a temperature of 120-130°C into the colloid mill, and keep stirring for 1min, that is Obtain uniform and fine asphalt emulsion.

[0044] The performance test data shows that the emulsified asphalt is cationic and can be stored stably for more than 5 days. The evaporation residue is 53.5%, and the residue on the sieve is 0.052%. It is slow-cracking when mixed with primary limestone mineral material. The initial setting time is 140min. It meets the requirements of "Technical Specifications for Hi...

Embodiment 3

[0046] Preparation of emulsifier: 25.12g (0.1mol) of soybean acid was changed to 26.18g (0.1mol) of tall oil fatty acid, and the remaining steps were referred to Example 1. The target emulsifier was obtained. Among them, m=10, r=4, n=14

[0047] Preparation of aqueous emulsifier solution: Example 1 was repeated.

[0048] Preparation of asphalt emulsion: Example 1 was repeated.

[0049] The performance test data shows that the emulsified asphalt is cationic and can be stored stably for more than 5 days. The evaporation residue is 52.8%, and the residue on the sieve is 0.039%. 135min. It meets the requirements of "Technical Specifications for Highway Asphalt Construction".

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com