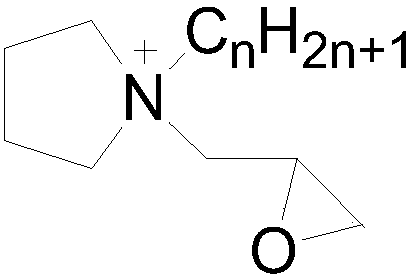

A cationic slow-cracking and fast-setting asphalt emulsifier with steric hindrance

A technology of asphalt emulsifier and steric hindrance, which is applied in organic chemistry, building components, building insulation materials, etc., can solve problems such as difficult control, complex process, and insufficient mild conditions, and achieve cheap raw materials, simple process routes, and high quality raw materials. Effects at an affordable price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

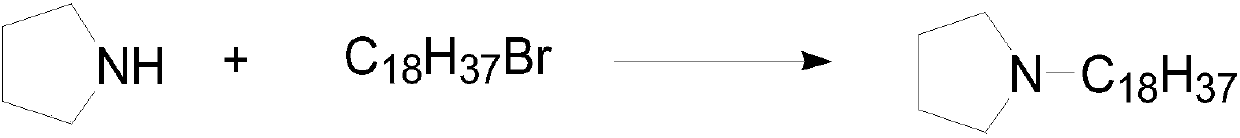

[0029] One, the preparation of intermediate B

[0030] Dissolve 4.66g (0.014mol) bromooctadecane in 15ml of ethyl acetate (the amount of ethyl acetate can dissolve bromooctadecane), and dissolve 0.40g (0.01mol) NaOH in 10ml of ethanol In aqueous solution (ethanol: distilled water = 4:1 volume ratio), the two parts of the solution were placed in a 100ml three-necked flask, and reacted at 30°C for 20min under magnetic stirring. Under nitrogen protection, 1.5ml (0.015mol) tetrahydropyrrole was dissolved In 5ml of ethyl acetate (the amount of ethyl acetate can dissolve tetrahydropyrrole), put it in a constant pressure dropping funnel and slowly drop it into a three-necked flask. After 15 minutes, the dropwise addition is completed, and then the reaction is carried out under magnetic stirring at 55°C for 6 hours. Rotary evaporation at 50°C, the solvent was evaporated, the product was washed with distilled water at 40°C, filtered with suction, and dried in vacuum at 40°C to obtain I...

Embodiment 2

[0048] One, the preparation of intermediate B

[0049] Dissolve 8.33g (0.025mol) bromooctadecane in 25ml ethyl acetate, dissolve 0.60g (0.015mol) NaOH in 15ml aqueous alcohol solution (absolute ethanol: distilled water = 4:1), the two parts The solution was placed in a 100ml three-neck flask, and reacted at 30°C for 20min under magnetic stirring. Under nitrogen protection, 3ml (0.03mol) of tetrahydropyrrole was dissolved in 10ml of ethyl acetate, and slowly dropped into the constant pressure dropping funnel. In the there-necked flask, the dropwise addition was completed in 20 minutes, the reaction was carried out under magnetic stirring at 55°C for 6 hours, the solvent was evaporated by rotary evaporation at 50°C, the product was washed with distilled water at 40°C, suction filtered, and vacuum-dried at 40°C to obtain Intermediate B.

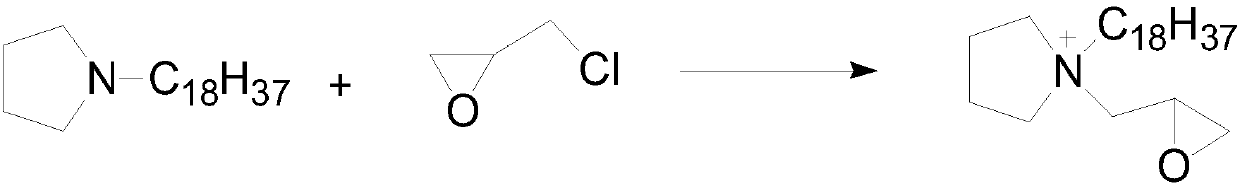

[0050] Two, the preparation of product A

[0051] Dissolve 6.46g (0.02mol) of intermediate B in 30ml of absolute ethanol, add it to a 100ml th...

Embodiment 3

[0056] 1. Preparation of cationic asphalt emulsifier with steric hindrance

[0057] Except that the time in the preparation of intermediate B was changed to 8h, others were the same as in Example 2 to obtain an asphalt emulsifier for future use.

[0058] 2. Preparation of emulsified asphalt:

[0059] According to the method of Example 1, the emulsifier obtained above was used to emulsify asphalt.

[0060] The properties of emulsified asphalt are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com