One-pot process for synthesizing permanent violet RL

A technology of permanent violet and process, applied in the direction of bisazine oxazine dyes, etc., can solve the problems of high labor intensity, high safety hazard, and the whole process cannot be automated, and achieves the effect of high labor intensity and simplified process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

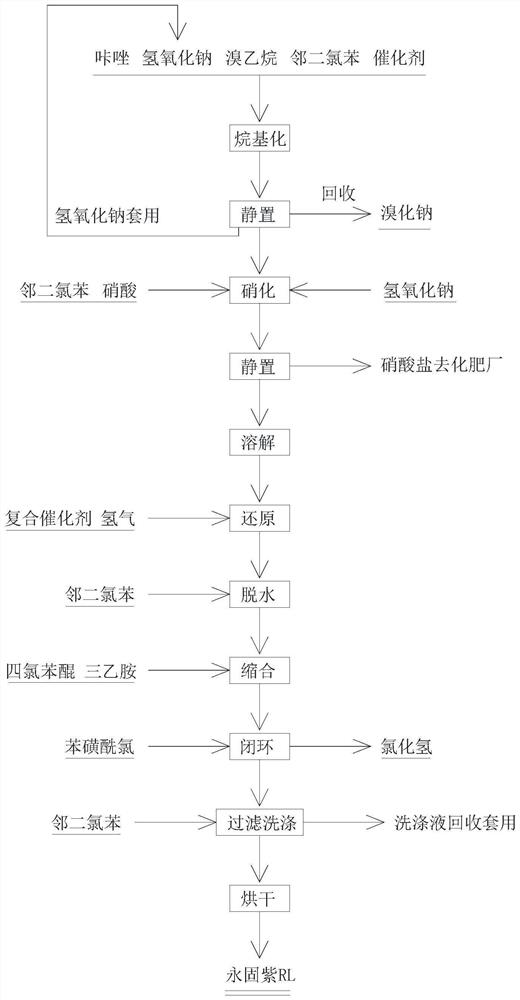

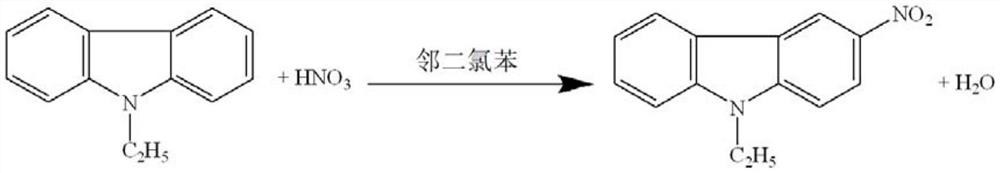

Method used

Image

Examples

Embodiment 1

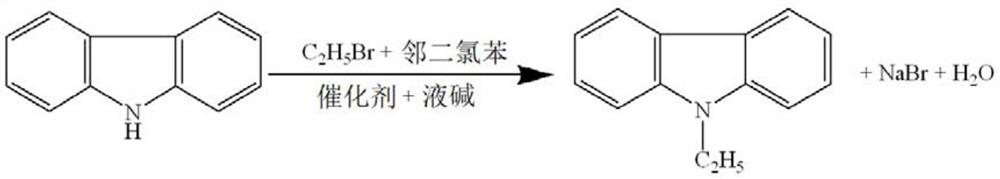

[0034] Alkylation process

[0035] 1. Through the liquid caustic soda pump, put 900L of prepared caustic soda into the alkylation pot, where the caustic caustic comes from the soda dispensing kettle;

[0036] 2. Open the manhole cover of the 3000L alkylation pot, put in 600 kg of carbazole and 6 kg of triethylbenzyl ammonium chloride catalyst, then cover and seal the reaction kettle, put in 310L o-dichlorobenzene through the metering barrel, and then pass Add 290L of ethyl bromide to the metering barrel first;

[0037] 3. Use micro-jacketed steam intermittently to trigger the reaction. If the temperature rises, the reaction starts. Turn off the steam, and the temperature will slowly rise to about 110°C and start to drop. At this time, turn on the steam to keep warm;

[0038] 4. When the solid carbazole in the alkylation pot disappears and turns into an oily liquid as the end point of the reaction, if necessary, take a sample to test the end point of the reaction;

[0039] 5....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com