Patents

Literature

61results about How to "Cumbersome process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

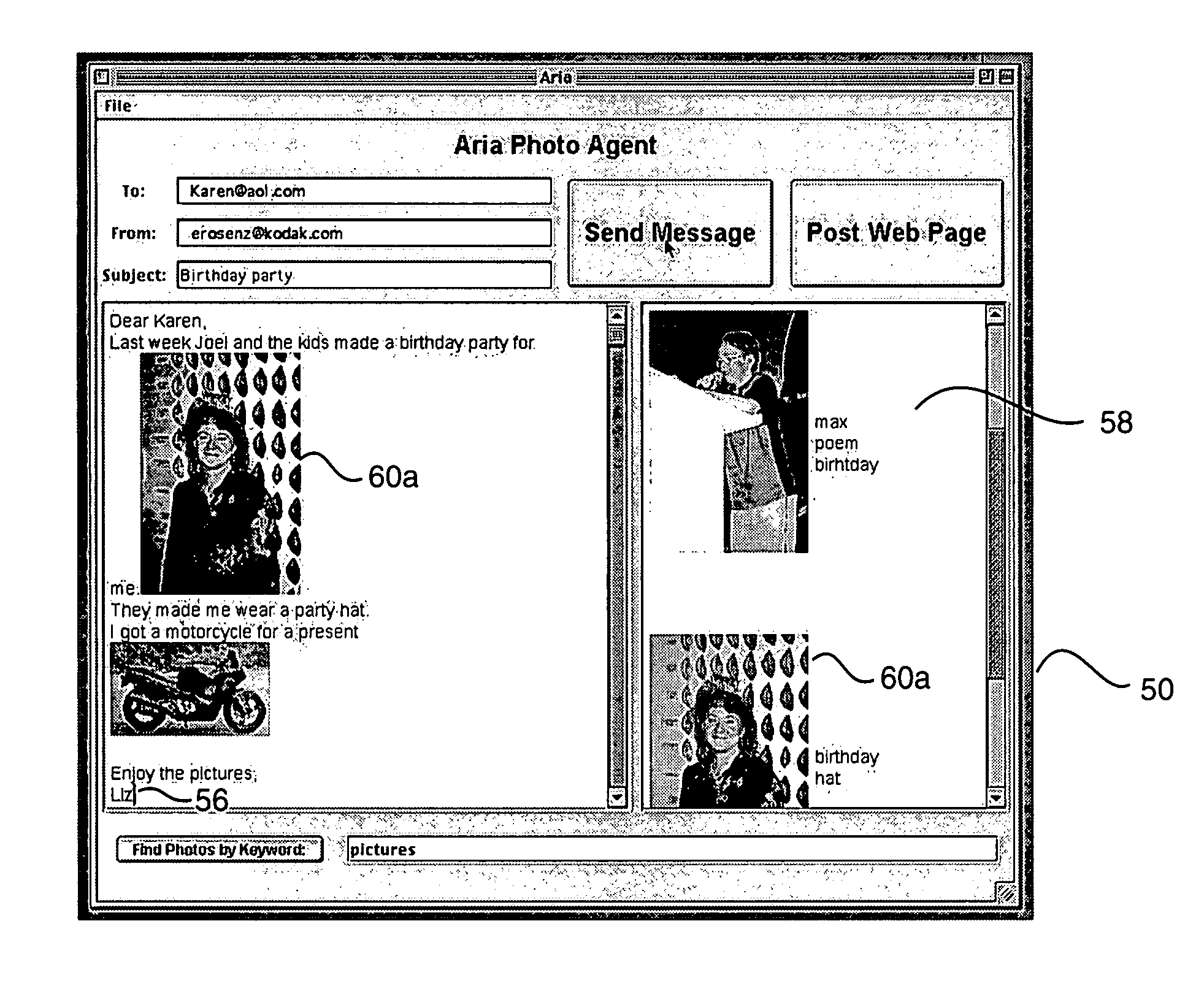

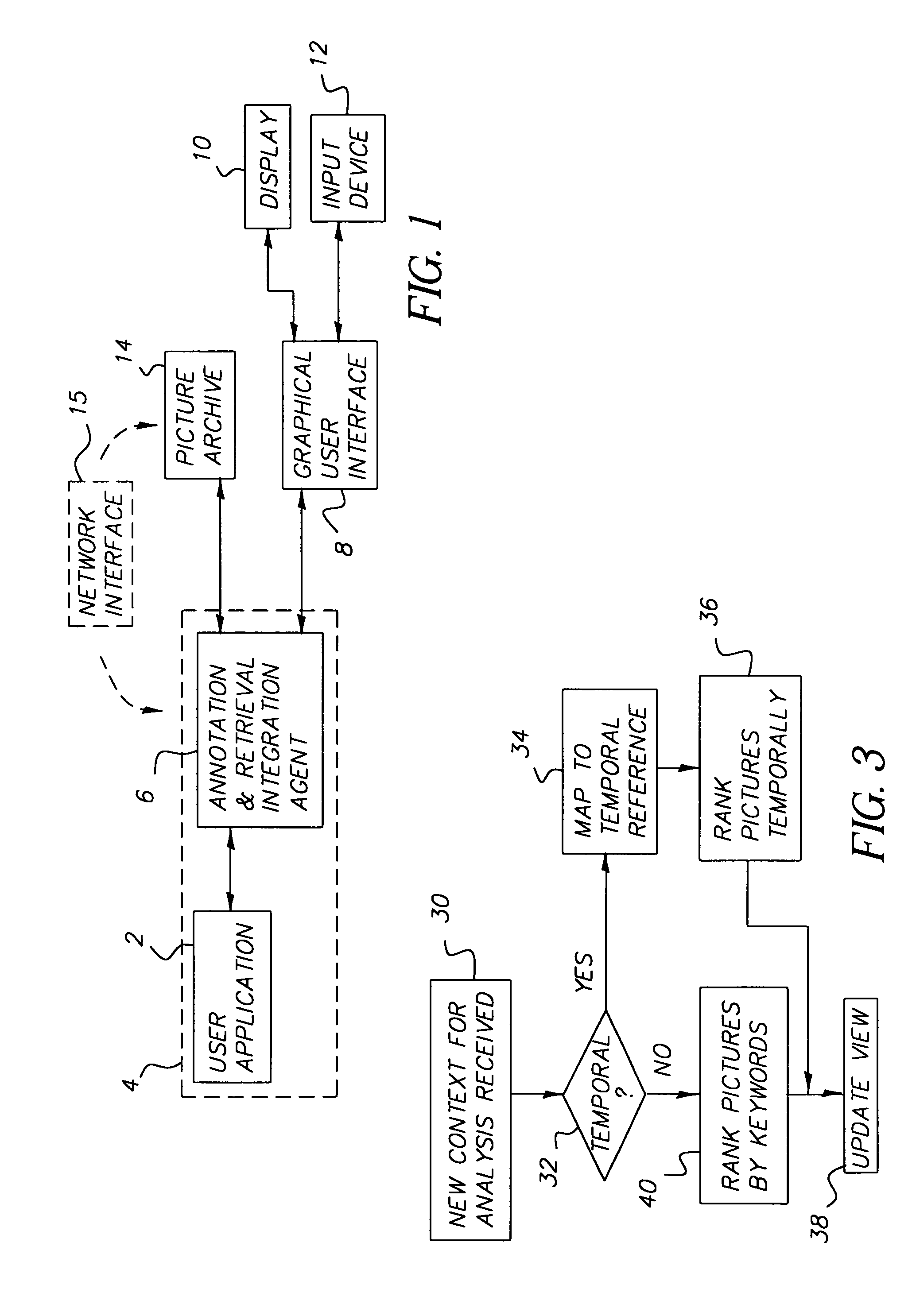

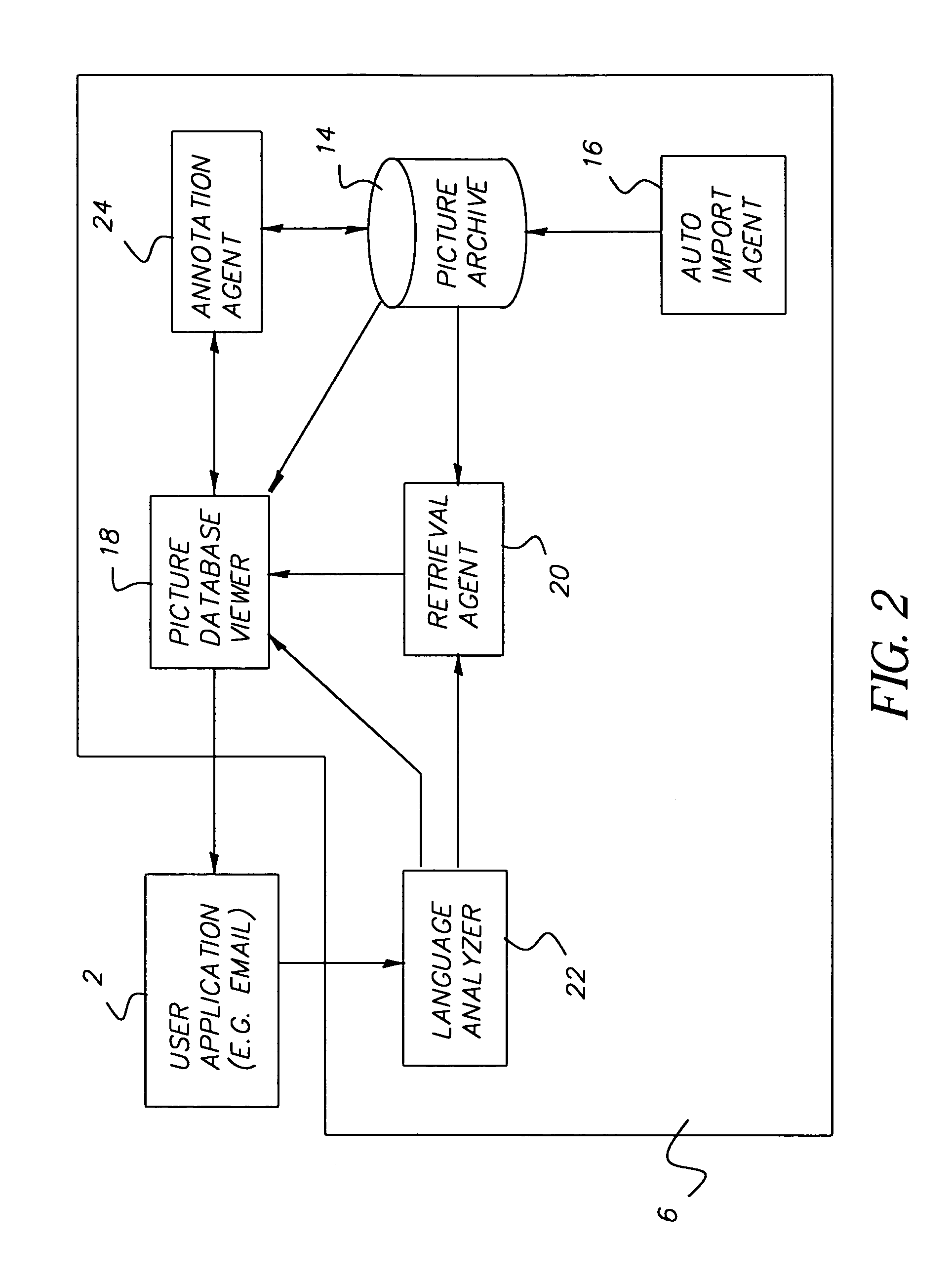

Agent for integrated annotation and retrieval of images

InactiveUS7028253B1Increase overheadCumbersome processData processing applicationsDigital computer detailsMetadataApplication software

A method for integrated retrieval and annotation of stored images involves running a user application in which text entered by a user is continuously monitored to isolate the context expressed by the text. The context is matched with metadata associated with the stored images, thereby providing one or more matched images, and the matched images are retrieved and displayed in proximity with the text. The context is then utilized to provide suggested annotations to the user for the matched images, together with the capability of selecting certain of the suggested annotations for subsequent association with the matched images. In a further extension, the method provides the user with the capability of inserting selected ones of the matched images into the text of the application, and further provides for automatically updating the metadata for the matched images.

Owner:MONUMENT PEAK VENTURES LLC

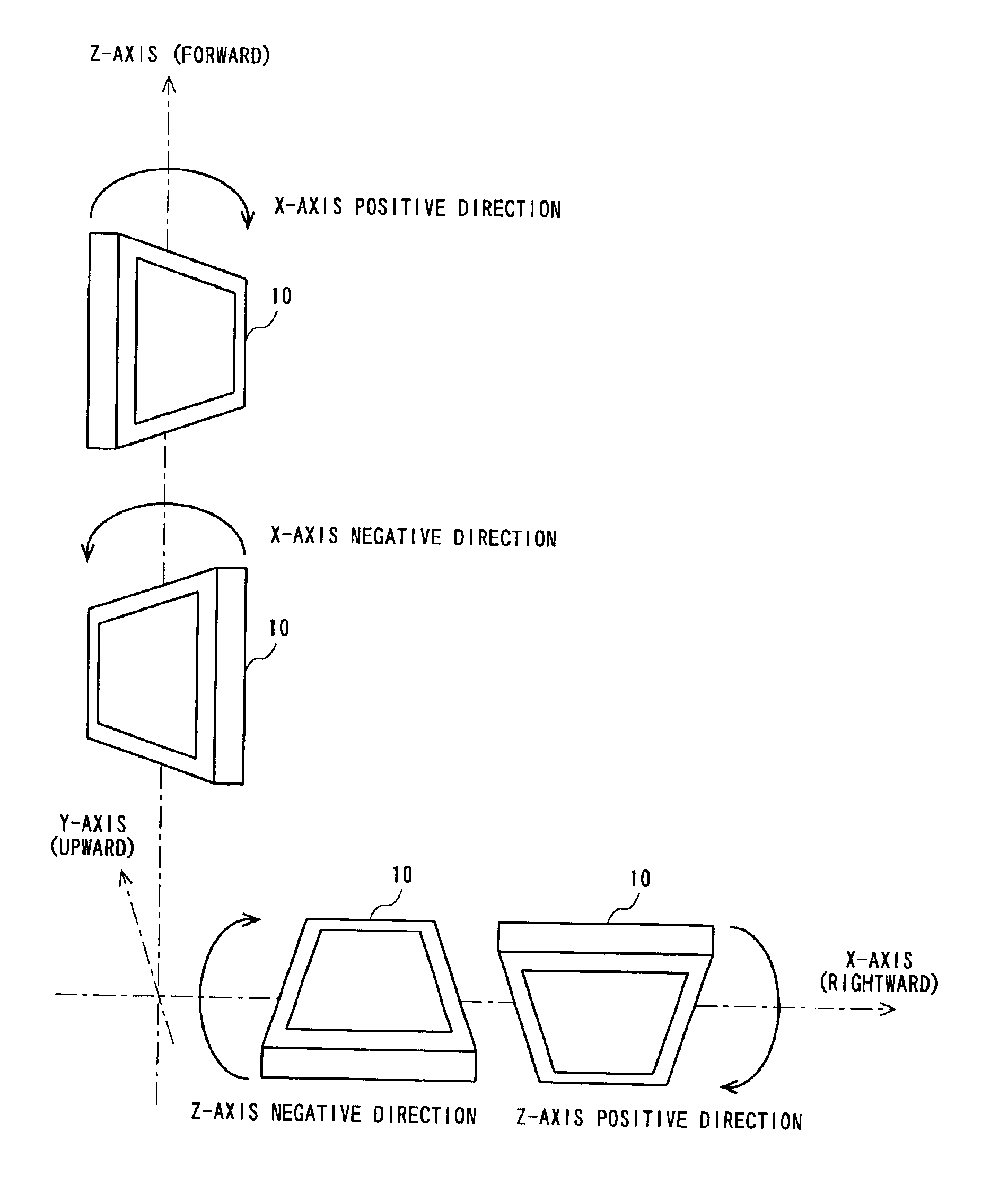

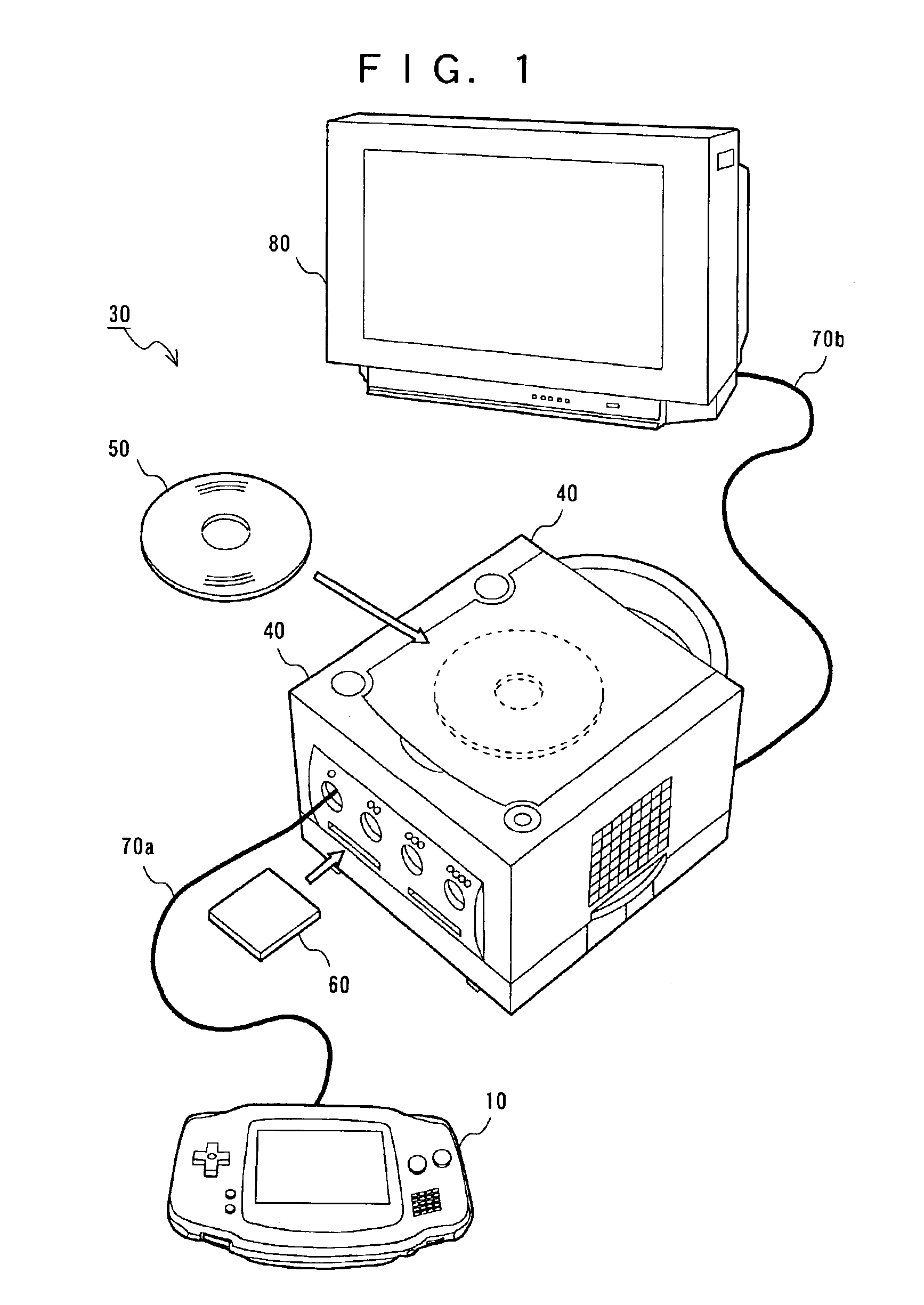

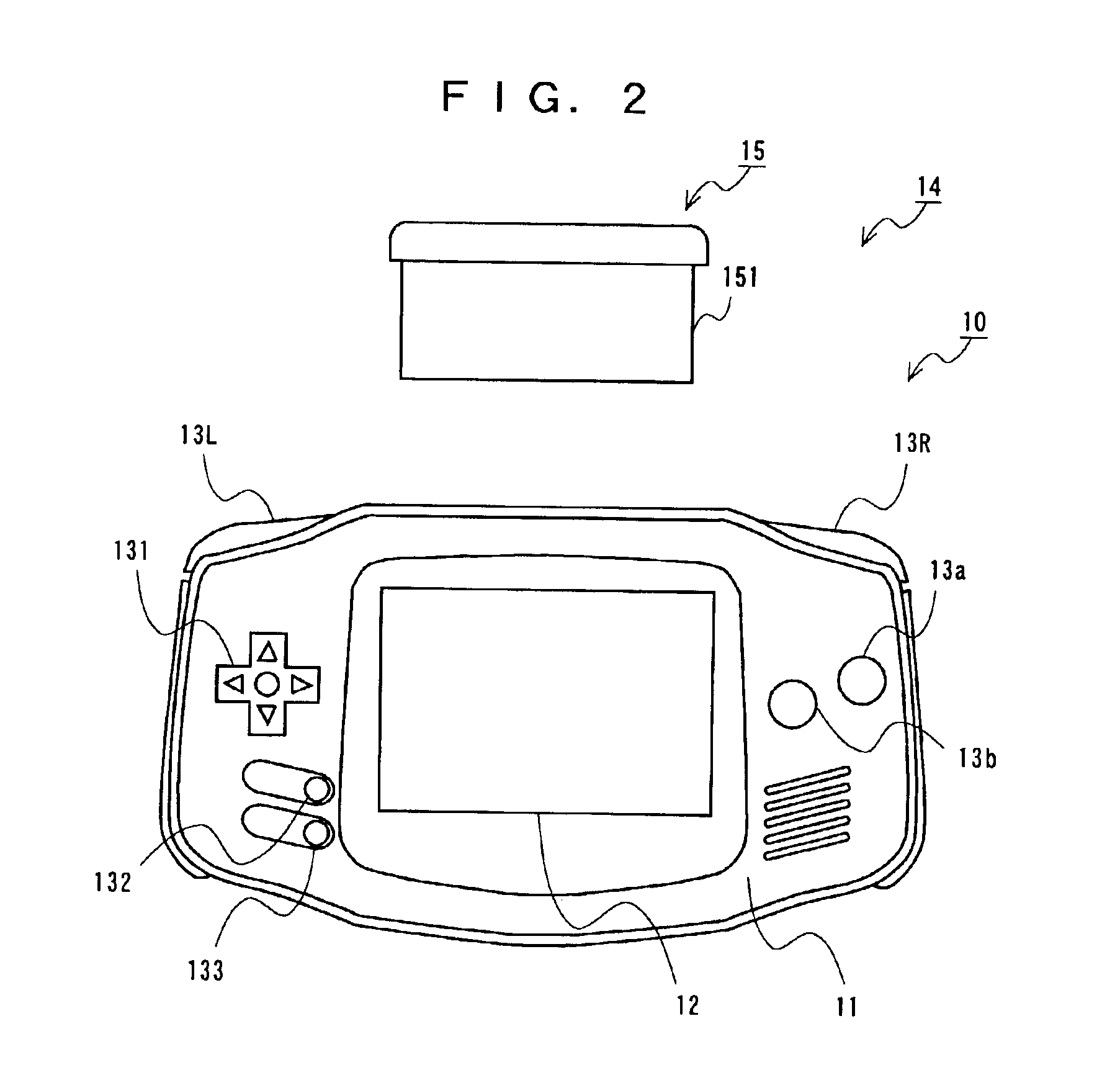

Game system with tilt sensor and game program including viewpoint direction changing feature

InactiveUS6908388B2Cumbersome processVideo gamesSpecial data processing applicationsViewpointsComputer graphics (images)

A game system displaying a three-dimensional game space on a display includes a housing held by a player, a tilt sensor provided on the housing, a viewpoint coordinates determination mechanism for determining viewpoint coordinates in accordance with an output value of the tilt sensor, and a game image generation processing mechanism for generating a game image based on the viewpoint coordinates determined by the viewpoint coordinates determination mechanism. The game system allows the player to feel as if the three-dimensional game space is tilted in accordance with a tilt of a game device, etc., with a minimal processing burden.

Owner:NINTENDO CO LTD

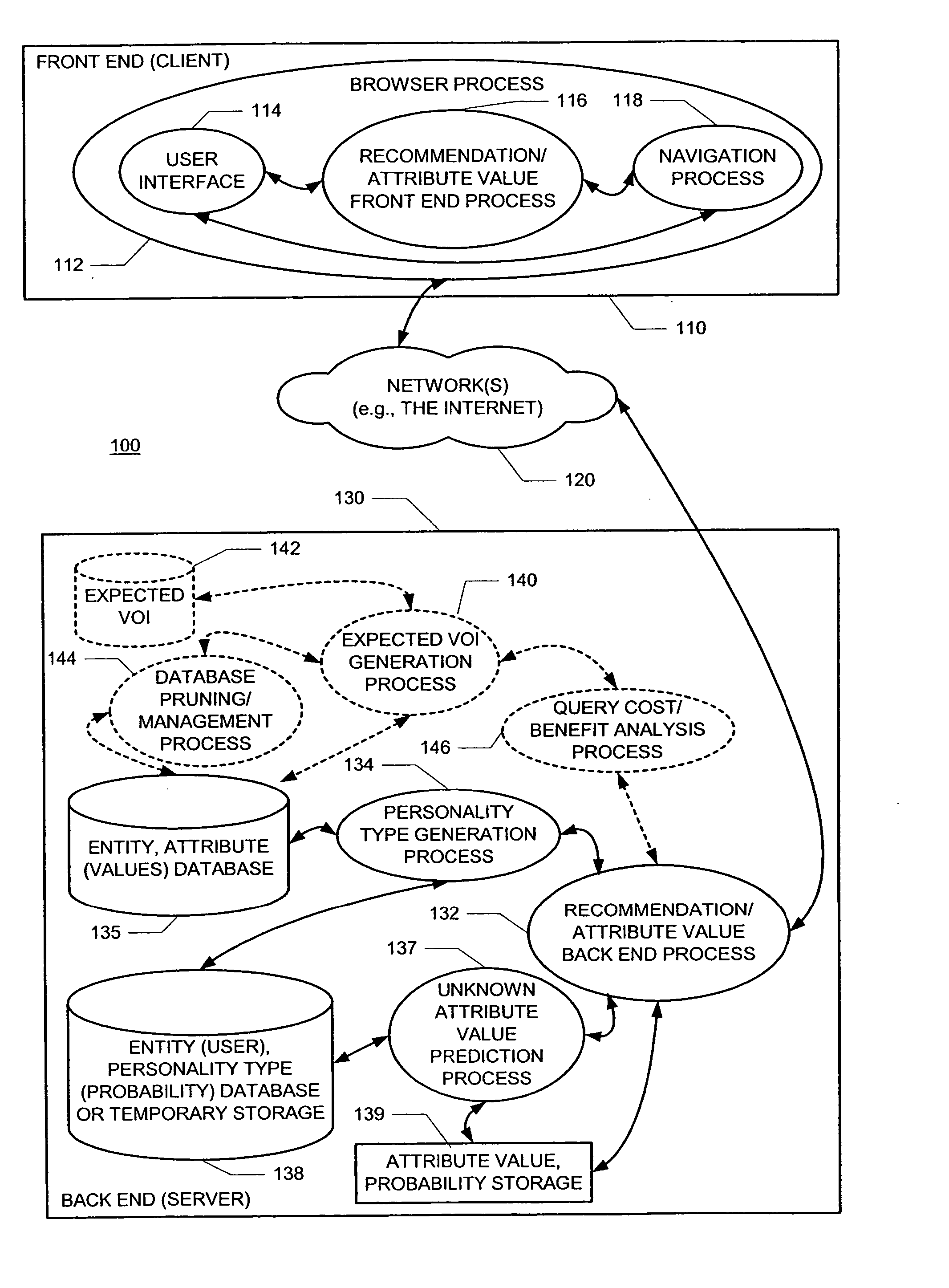

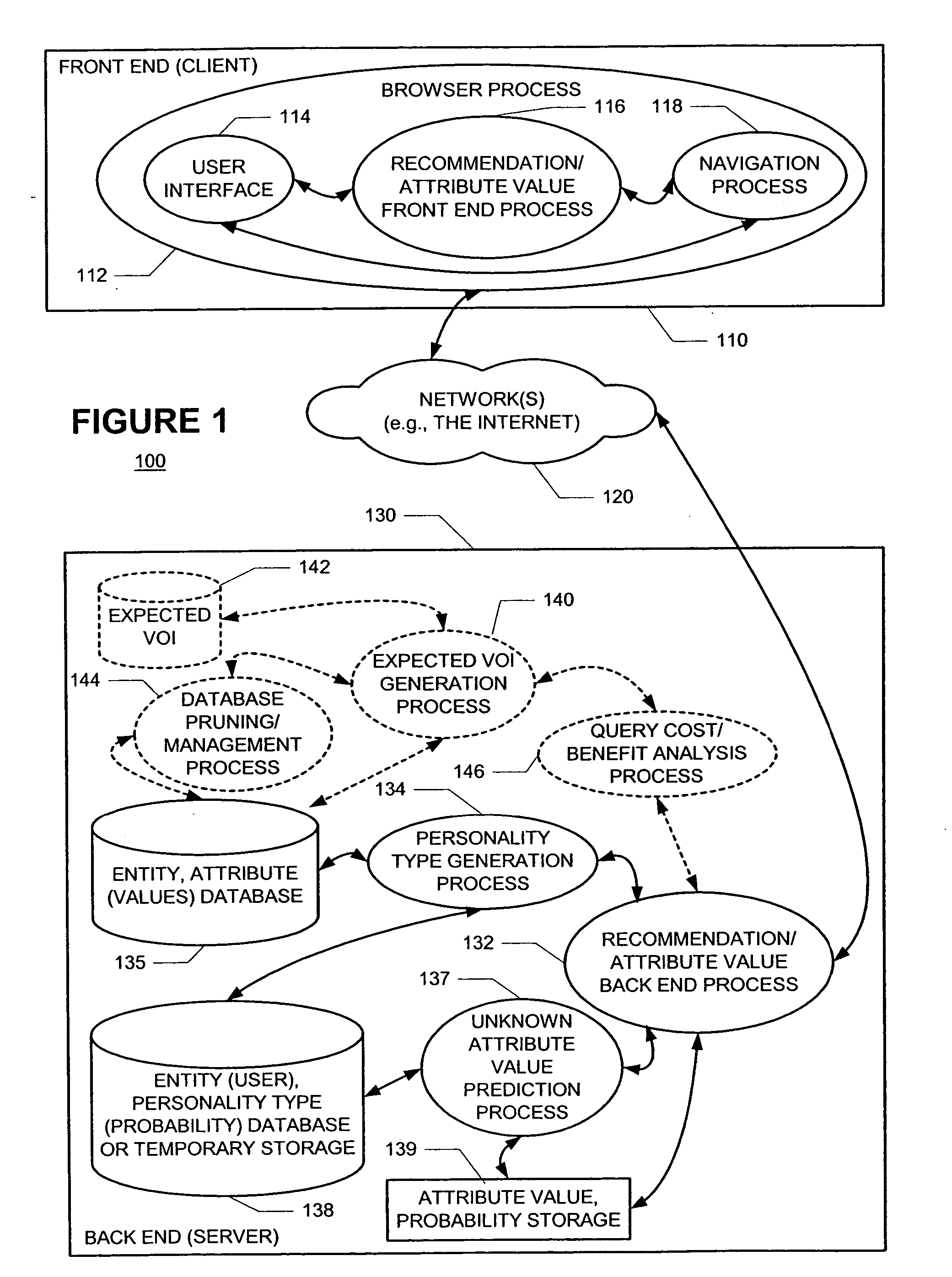

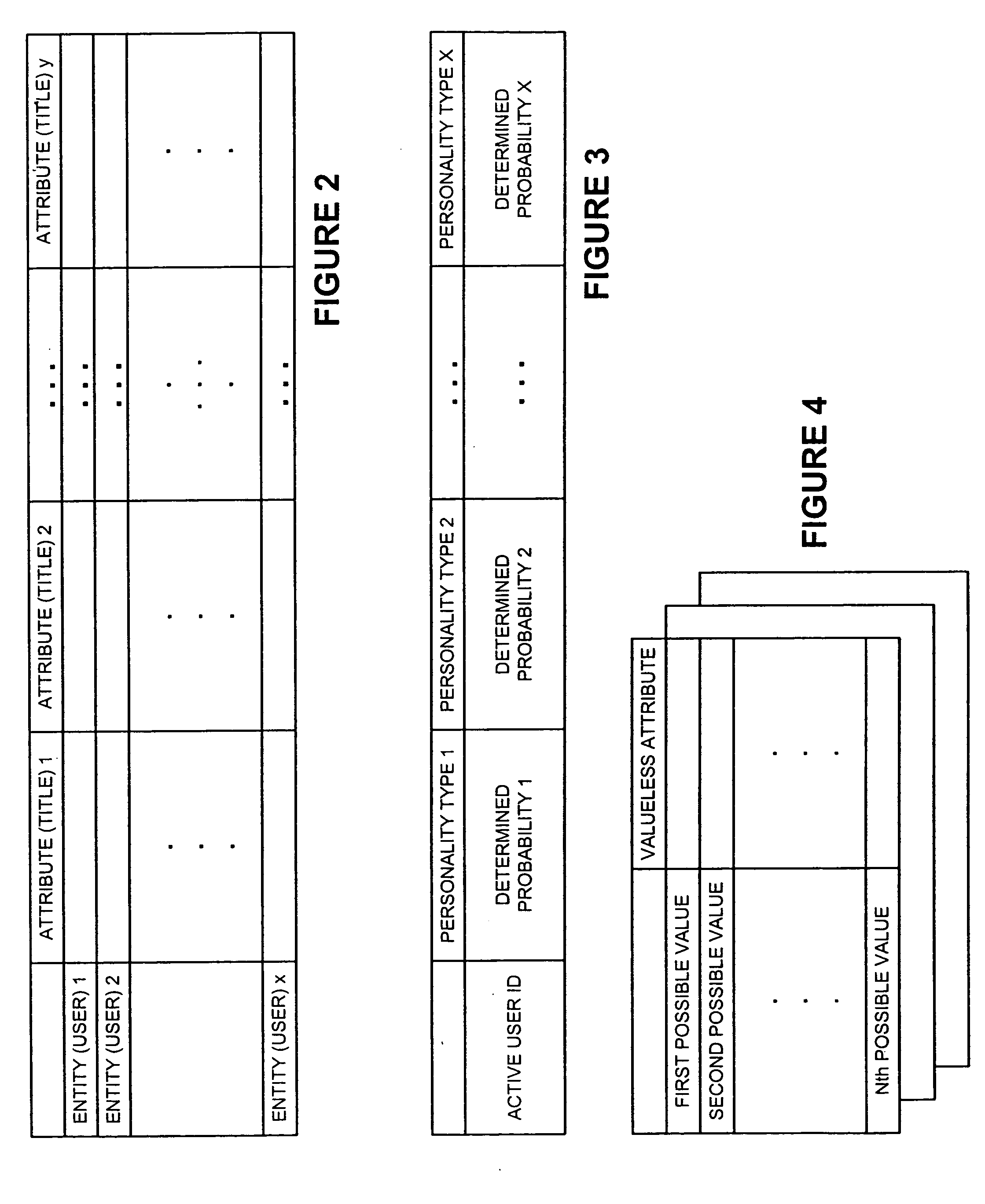

Methods and apparatus for predicting and selectively collecting preferences based on personality diagnosis

InactiveUS20040076936A1Minimal effectCumbersome processMarket predictionsBuying/selling/leasing transactionsProbabilistic semanticsValue of information

A new recommendation technique, referred to as "personality diagnosis", that can be seen as a hybrid between memory-based and model-based collaborative filtering techniques, is described. Using personality diagnosis, all data may be maintained throughout the processes, new data can be added incrementally, and predictions have meaningful probabilistic semantics. Each entity's (e.g., user's) reported attributes (e.g., item ratings or preferences) may be interpreted as a manifestation of their underlying personality type. Personality type may be encoded simply as a vector of the entity's (e.g., user's) "true" values (e.g., ratings) for attributes (e.g., items) in the database. It may be assumed that entities (e.g., users) report values (e.g., ratings) with a distributed (e.g., Gaussian) error. Given an active entity's (e.g., user's) known attribute values (e.g., item ratings), the probability that they have the same personality type as every other entity (e.g., user) may be determined. Then, the probability that they will have a given value (e.g., rating) for a valueless (e.g., unrated) attribute (e.g., item) may then be determined based on the entity's (e.g., user's) personality type. The probabilistic determinations may be used to determine expected value of information. Such an expected value of information could be used in at least two ways. First, an interactive recommender could use expected value of information to favorably order queries for attribute values (e.g., item ratings), thereby mollifying what could otherwise be a tedious and frustrating process. Second, expected value of information could be used to determine which entries of a database to prune or ignore-that is, which entries, which if removed, would have a minimal effect of the accuracy of recommendations.

Owner:MICROSOFT TECH LICENSING LLC

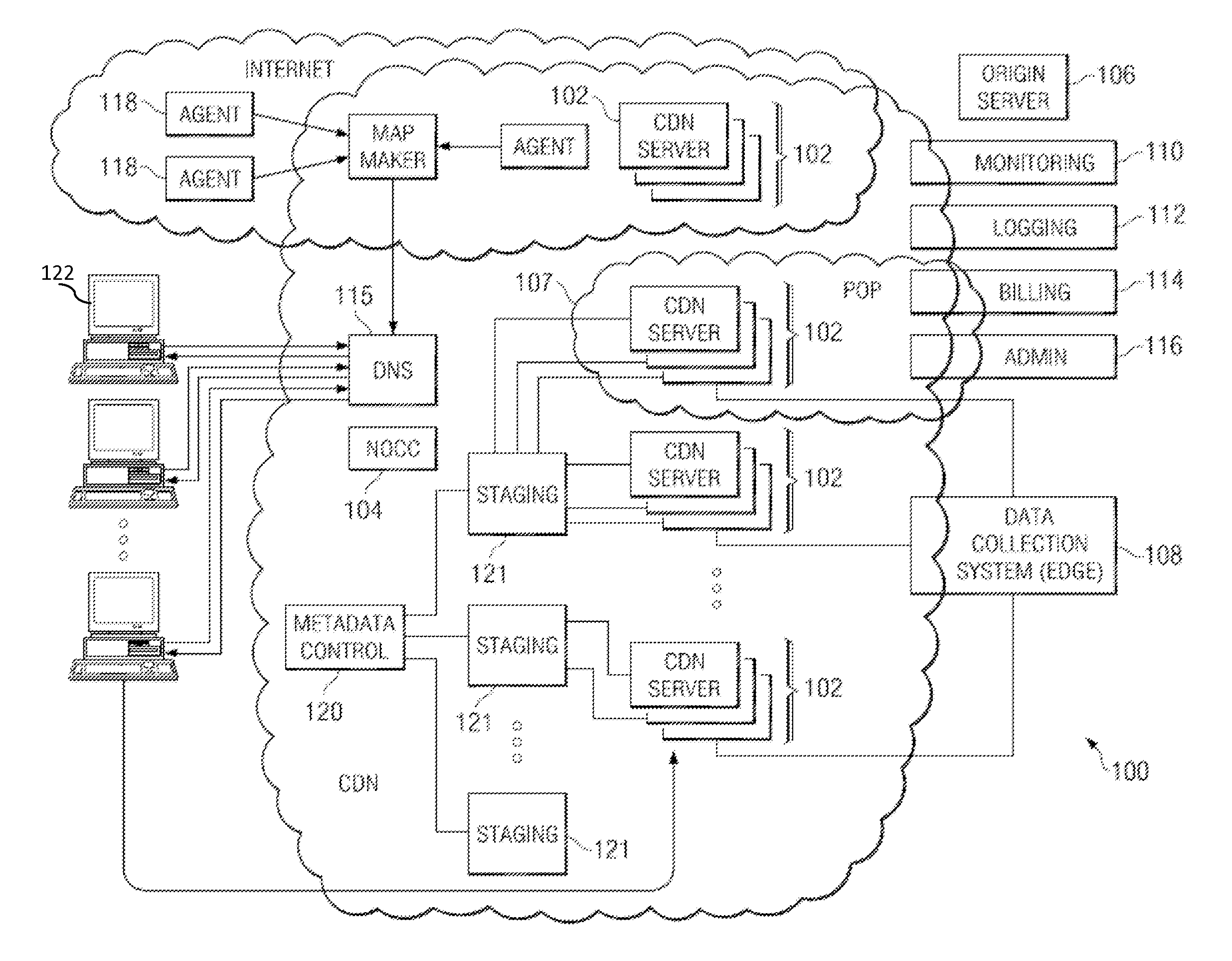

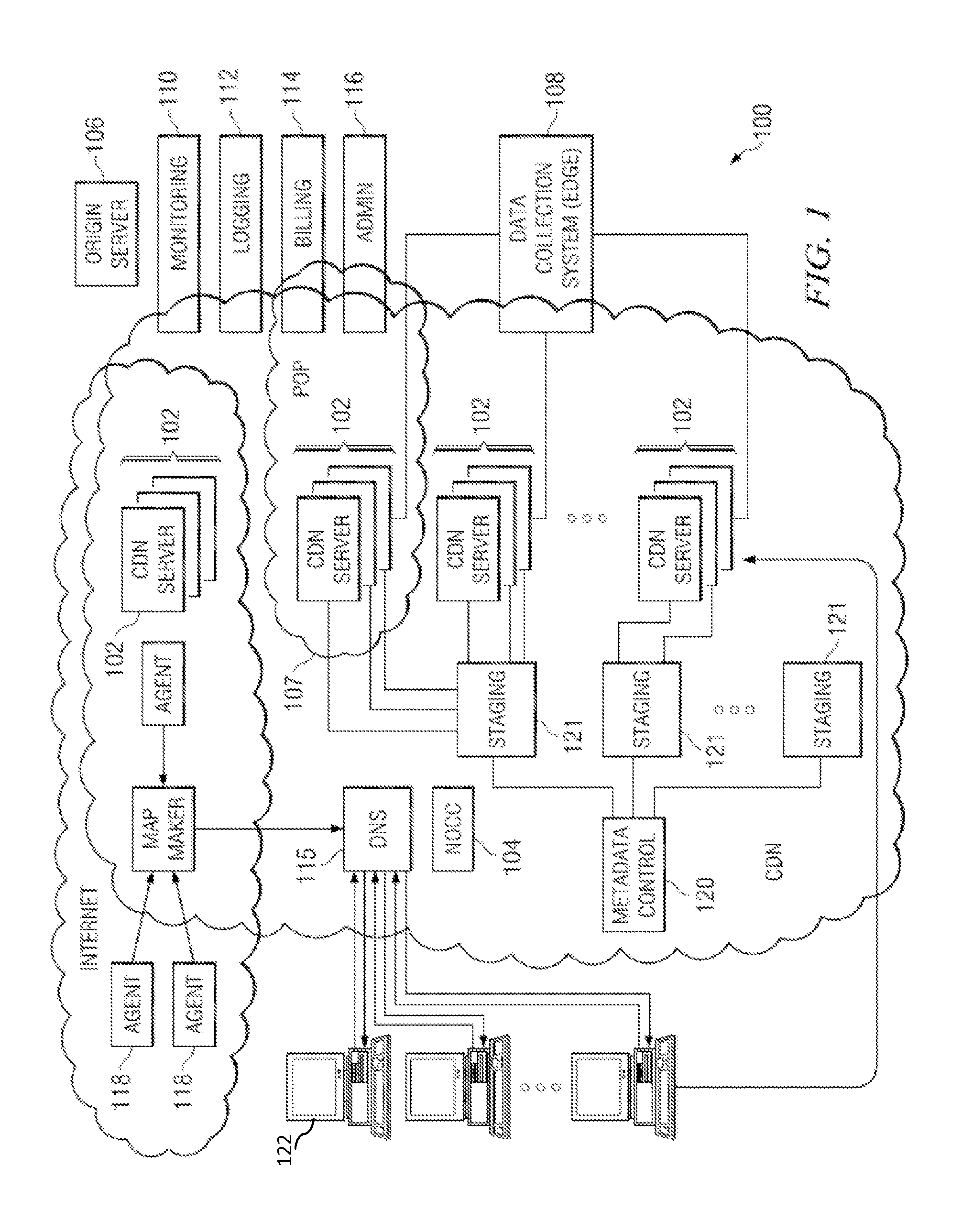

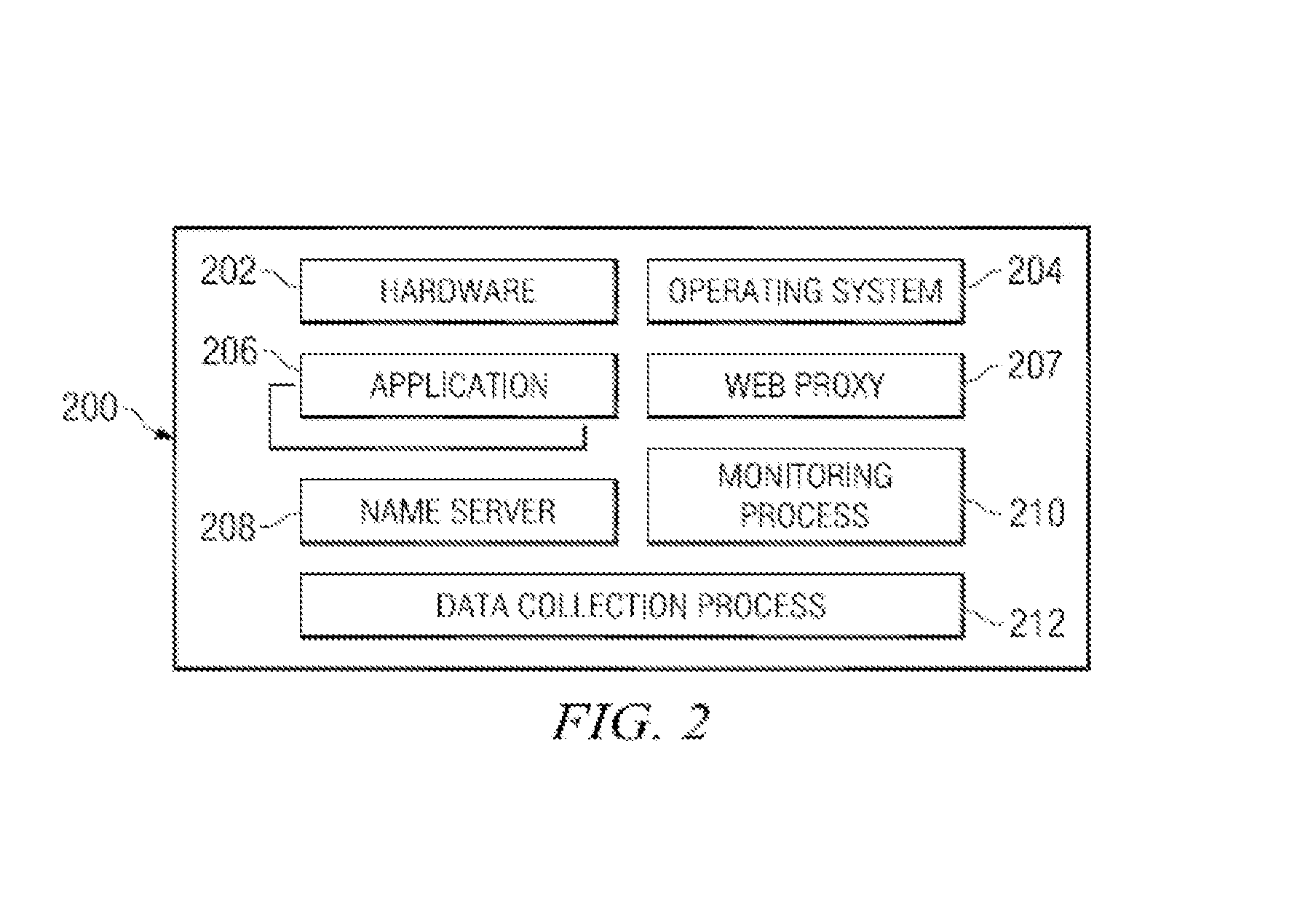

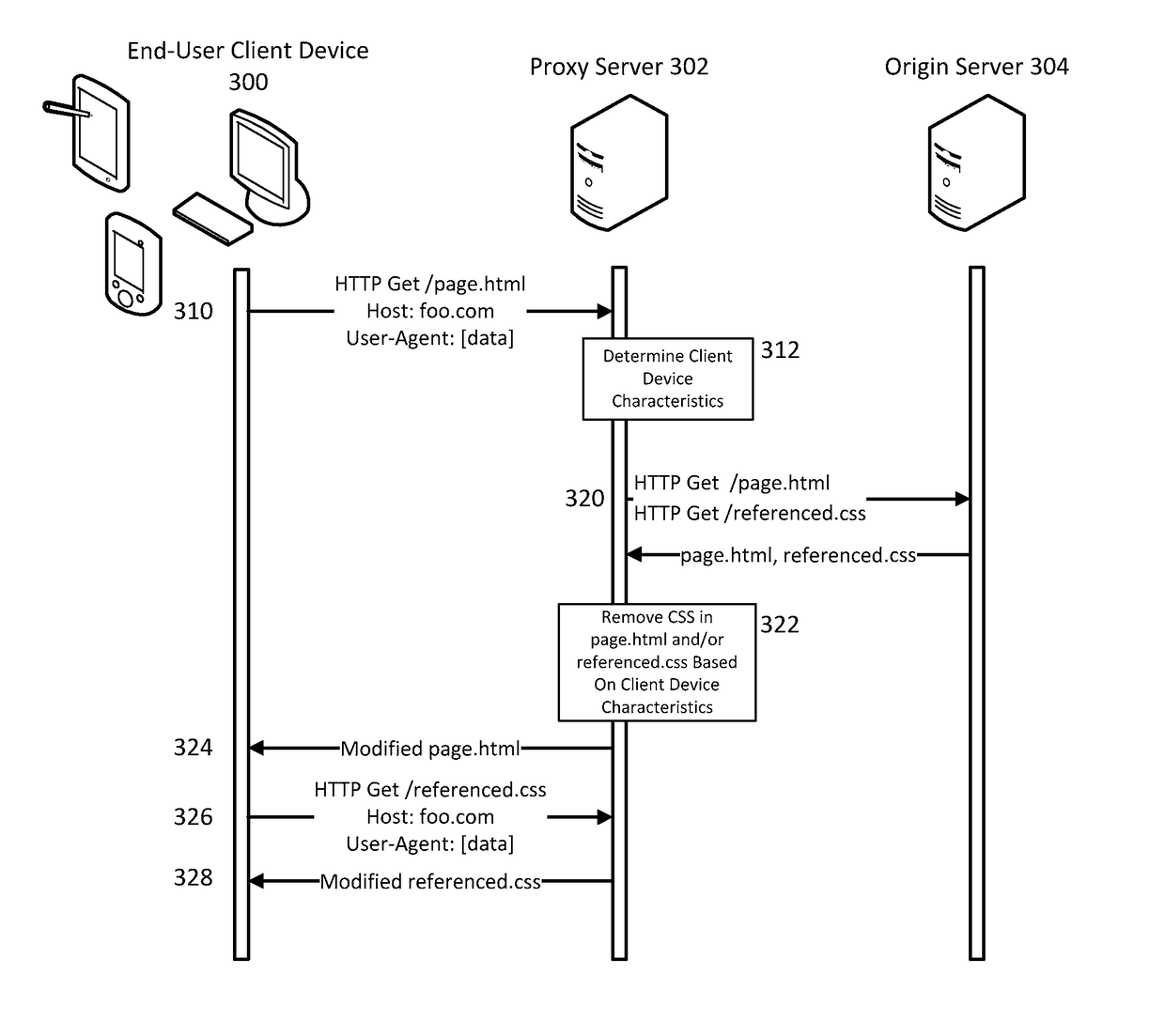

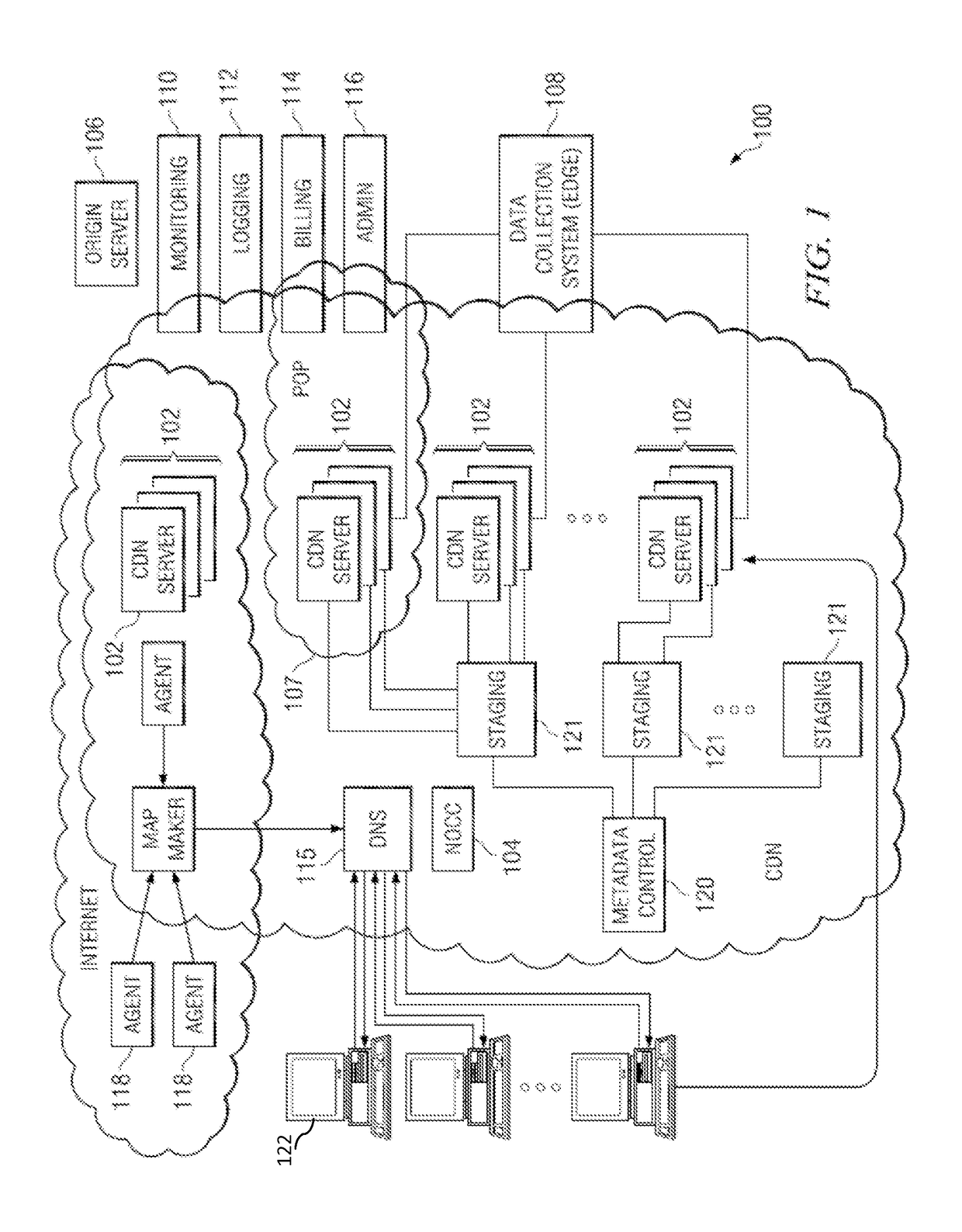

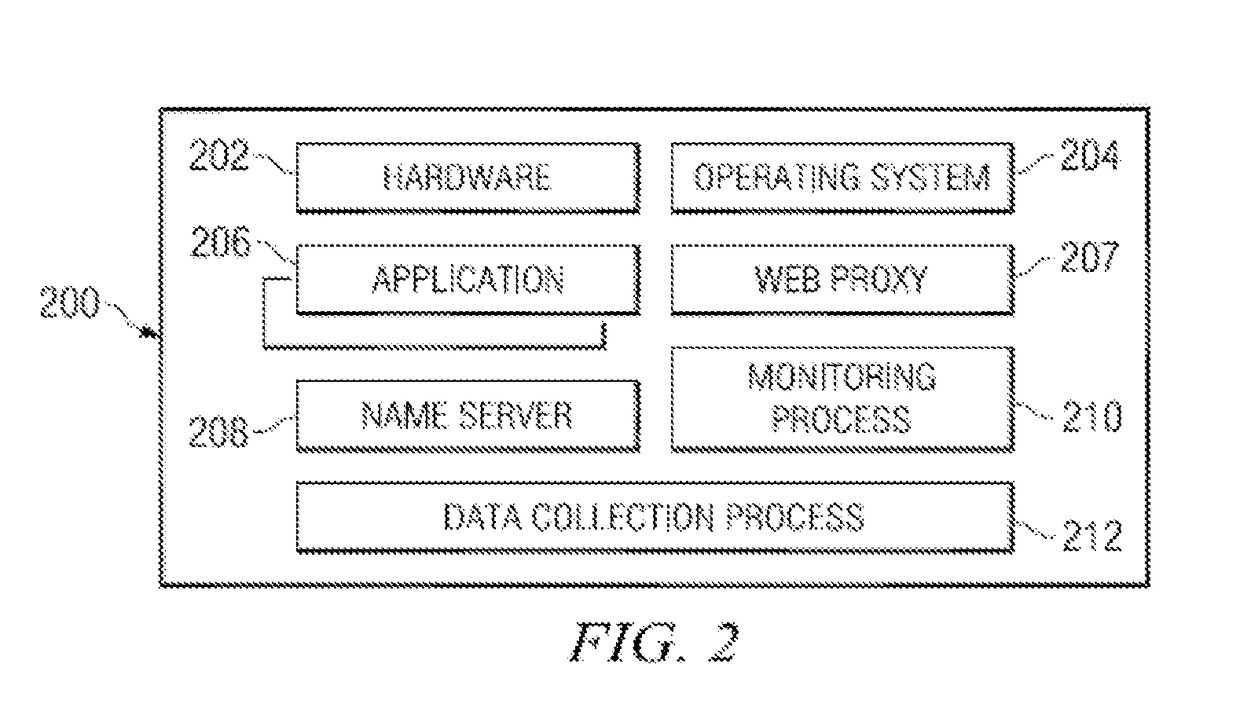

Methods and apparatus for accelerating content authored for multiple devices

ActiveUS20130219024A1Reduce deliveryEnhanced content deliveryMultiple digital computer combinationsWebsite content managementClient-sideProxy server

Disclosed herein are systems, methods, and apparatus for improving the delivery of web content that has been authored for multiple devices. In certain embodiments, an intermediary device such as a proxy server determines the characteristics of a client device requesting multi-device content, obtains and examines the multi-device content, and in view of the particular requesting client device removes portions that are irrelevant for that device. Doing so can accelerate delivery of the content by reducing payload and relieving the client device of the processing burden associated with parsing the content to make that determination itself, among other things.

Owner:AKAMAI TECH INC

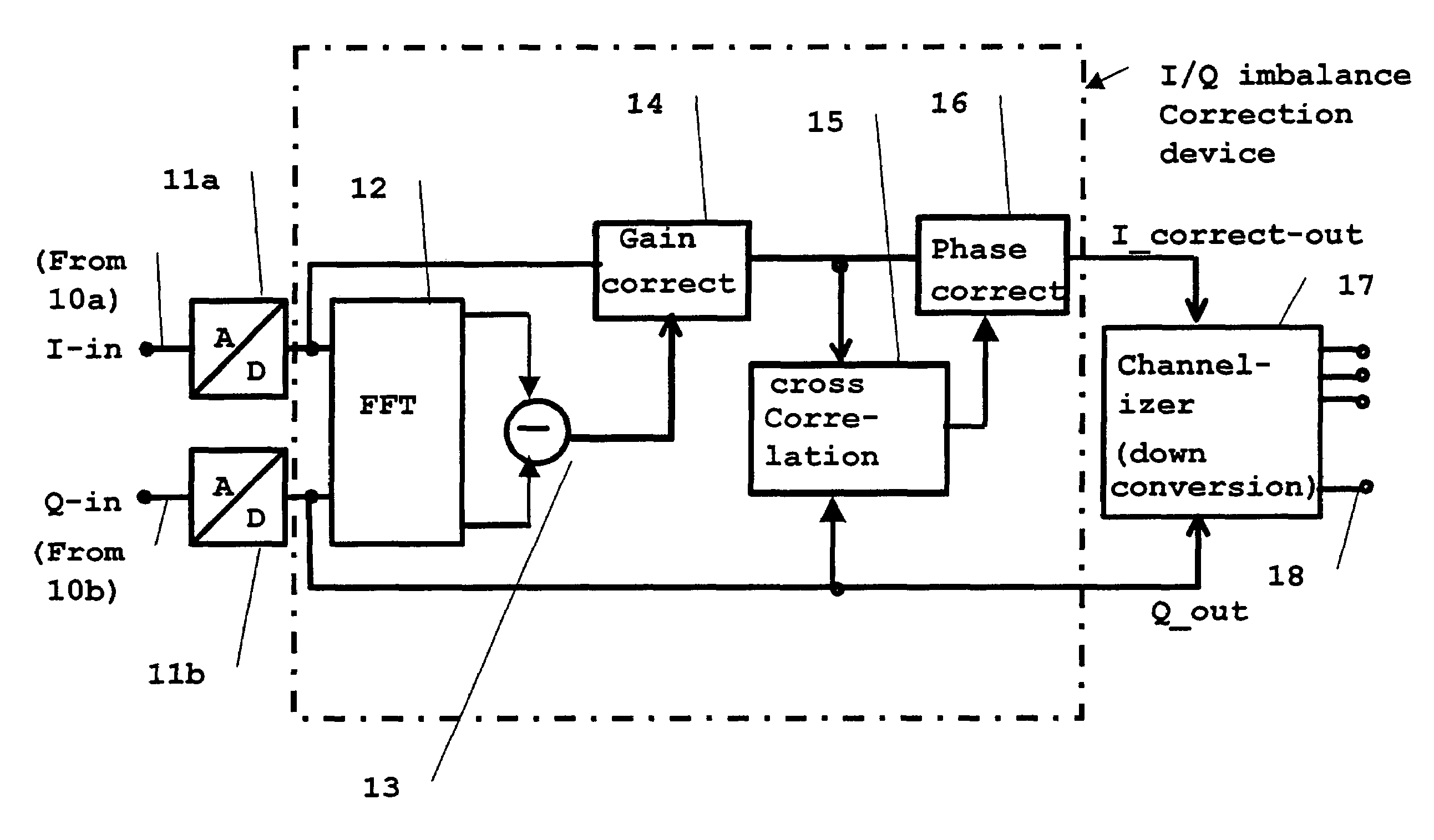

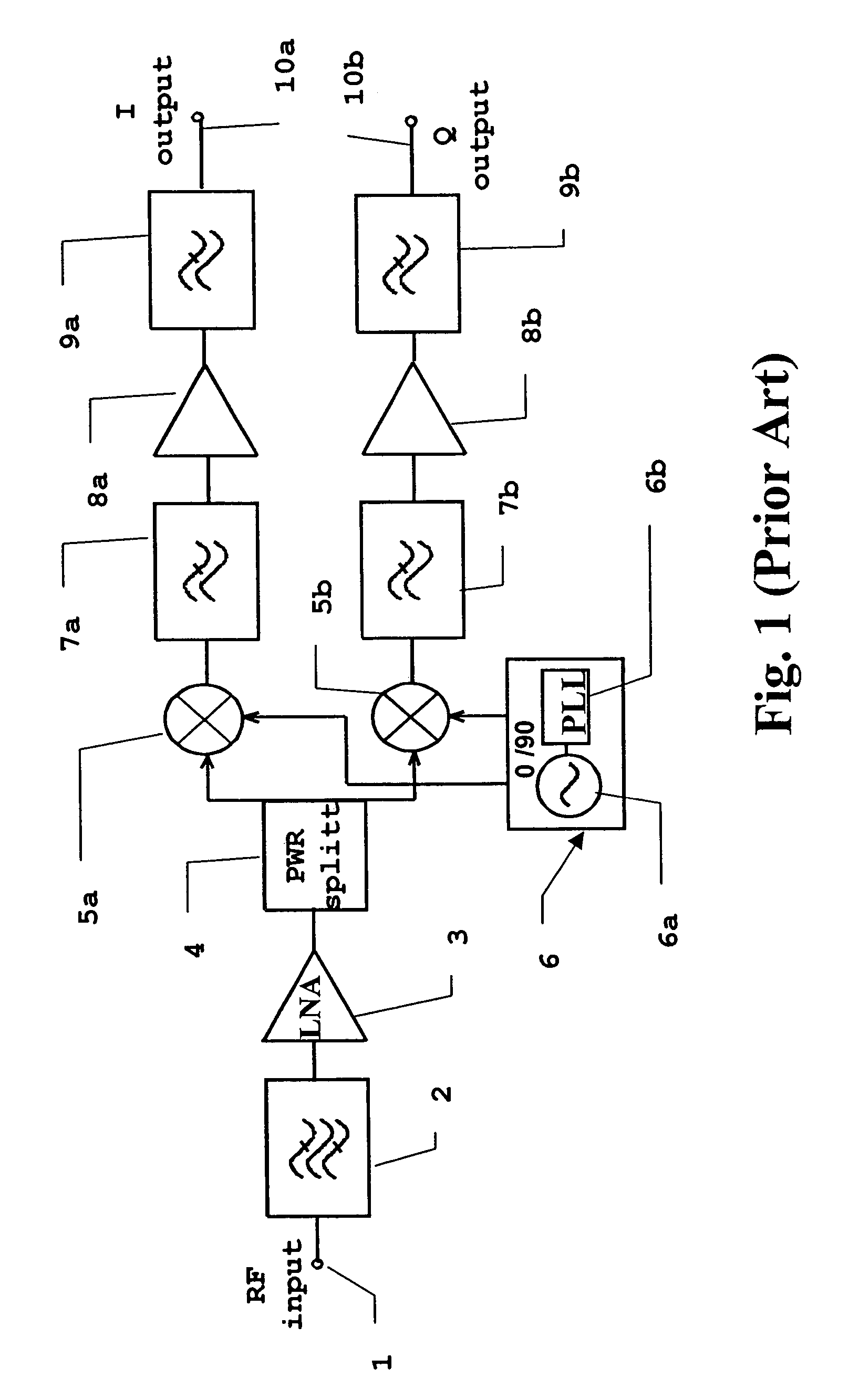

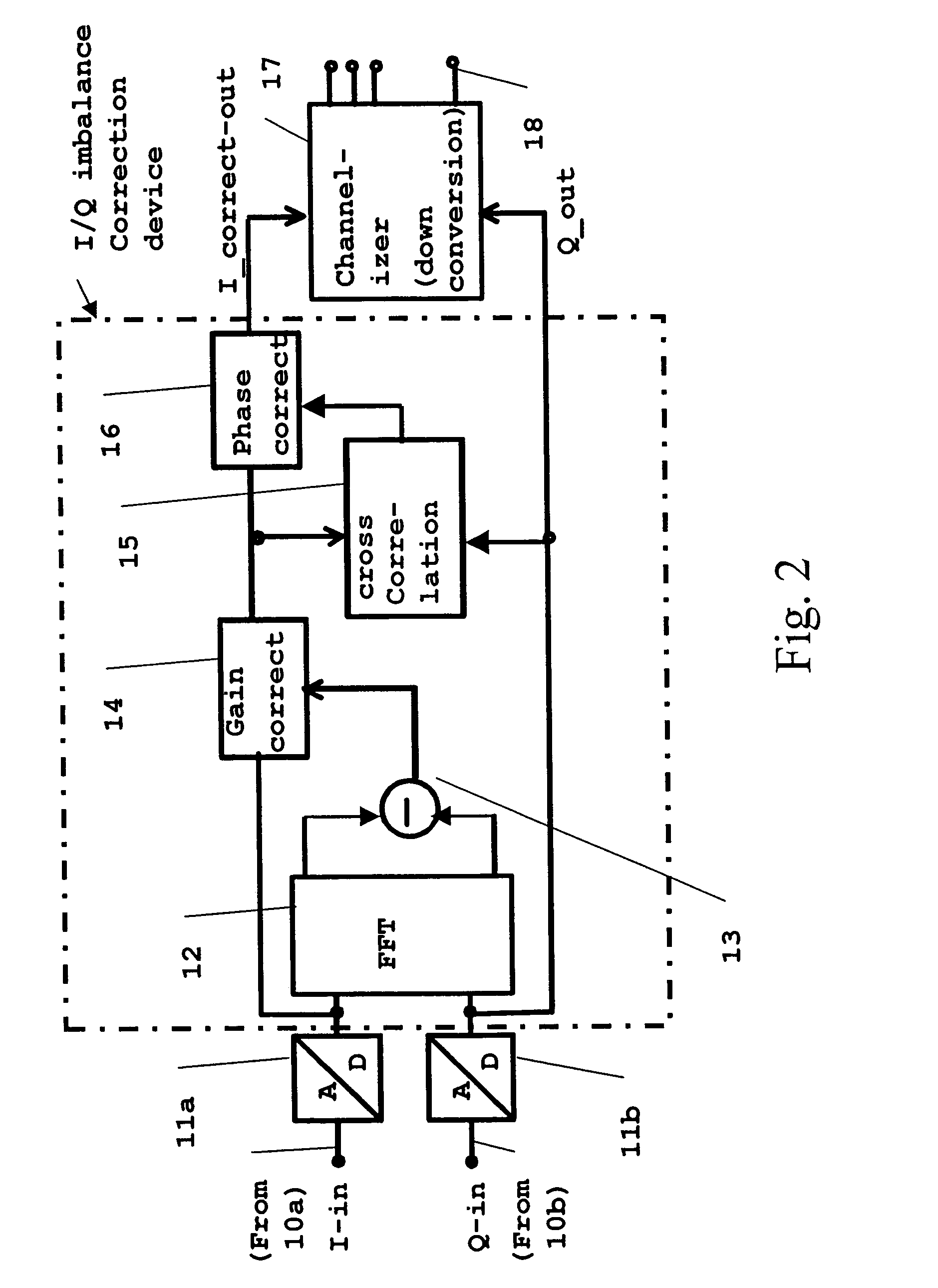

Digital imbalance correction method and device

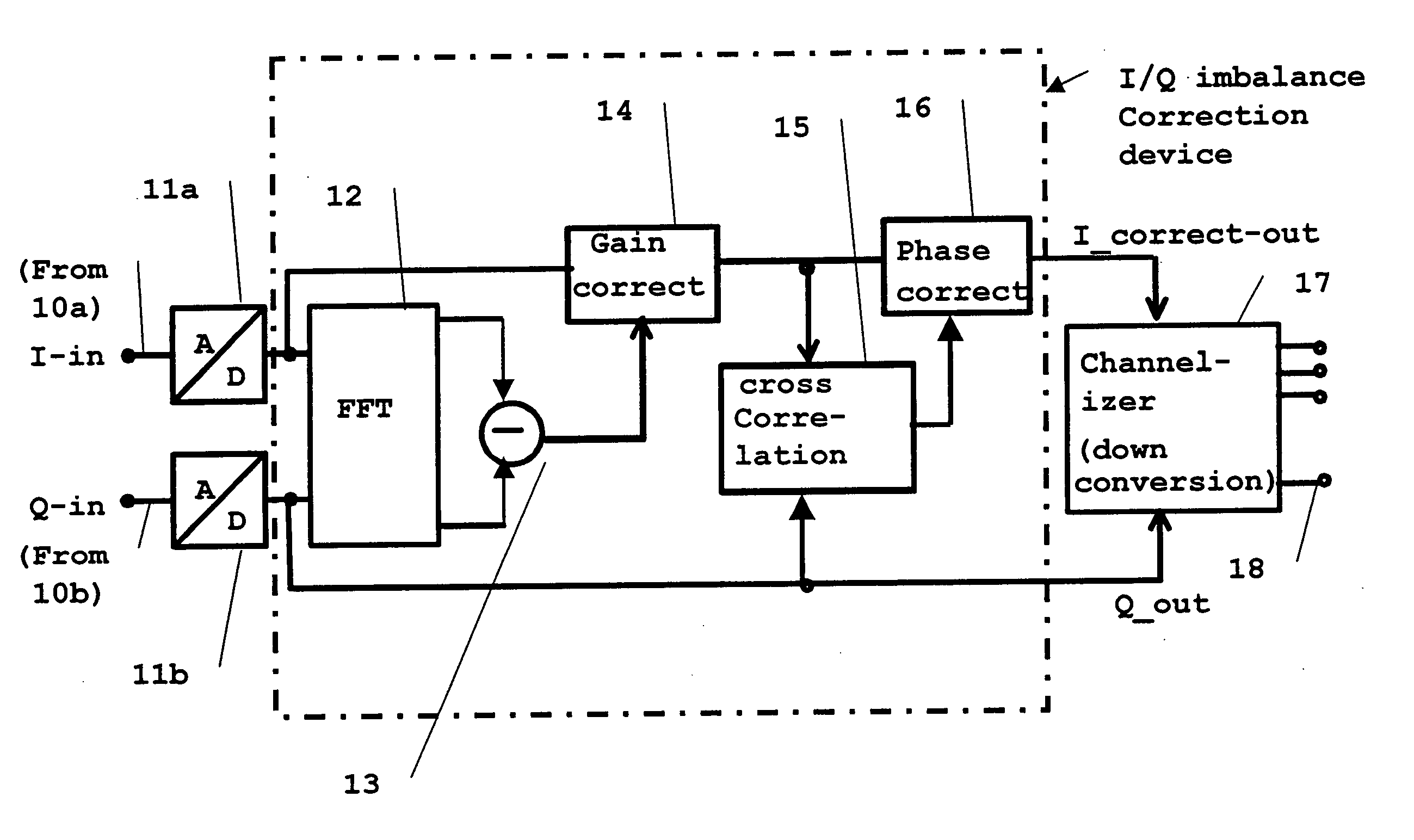

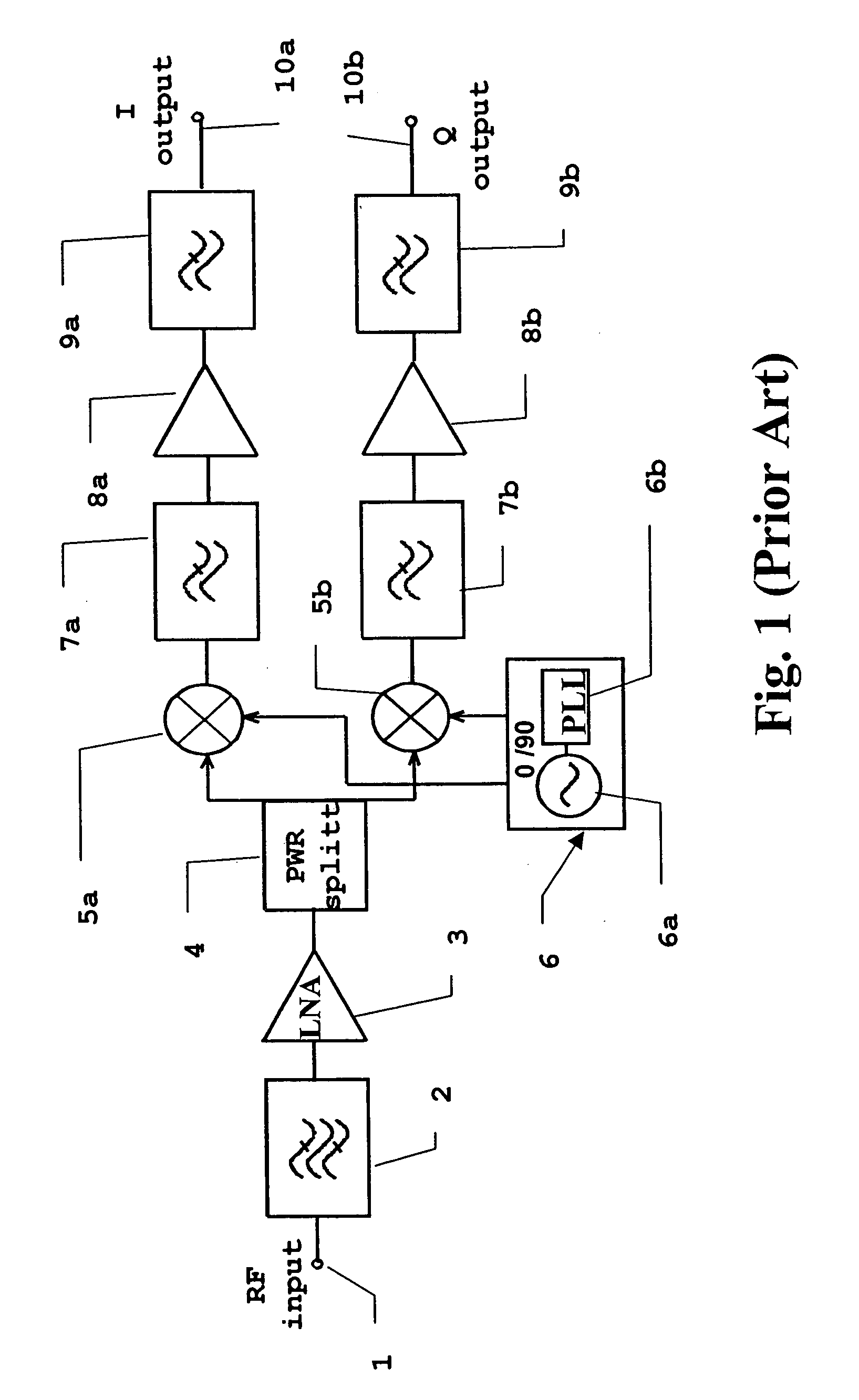

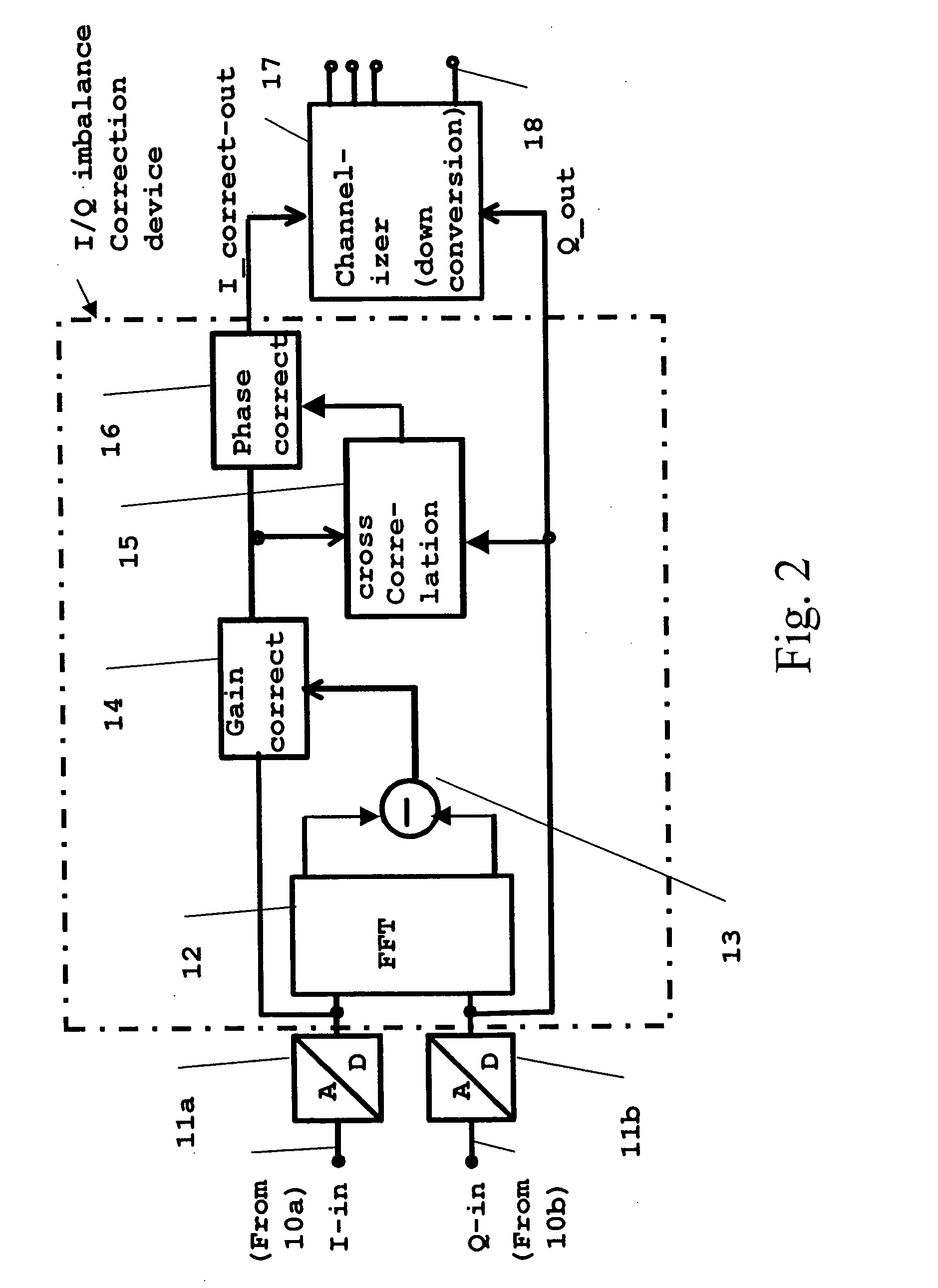

InactiveUS20040082300A1Cost of complexityAvoids very tedious frequency planning processResonant long antennasInterconnection arrangementsPower differencePhase correction

The present invention concerns a digital imbalance correction device, comprising input means adapted to receive first input signals I-in, Q-in containing a plurality of channels from an I / Q converter stage at respective input terminals, each input terminal being associated to a respective signal branch, a time-to-frequency-domain-transforming means FFT adapted to perform a transformation of said first input signals from time-domain into frequency-domain, the transformation result being represented as a power spectrum of said respective first input signals, a subtracting means arranged to receive at its inputs second input signals which are represented by the power spectra of said respective transformed first input signals and to output the gain difference as a function of frequency at its output, a cross-correlation means arranged to receive at its inputs third input signals based on said input signals, and to output a cross-correlation of said third input signals, said cross-correlation output being proportional to a phase error between said respective correlation input signals, a gain correction means arranged in one of said respective signal branches and receiving at its input a fourth input signal based said associated first input signal, wherein a gain of said fourth input signal is corrected based on said power difference spectrum such that said gain of said fourth input signal equals the gain of the other one of said first input signals, and a phase correction means arranged in one of said respective signal branches and receiving at its input a fifth input signal based said associated first input signal, wherein a phase of said fifth input signal is corrected based on said cross-correlation output, such that said phase of said fifth input signal is in quadrature relation to the other one of said first input signals. The present invention also concerns a corresponding method.

Owner:NOKIA CORP

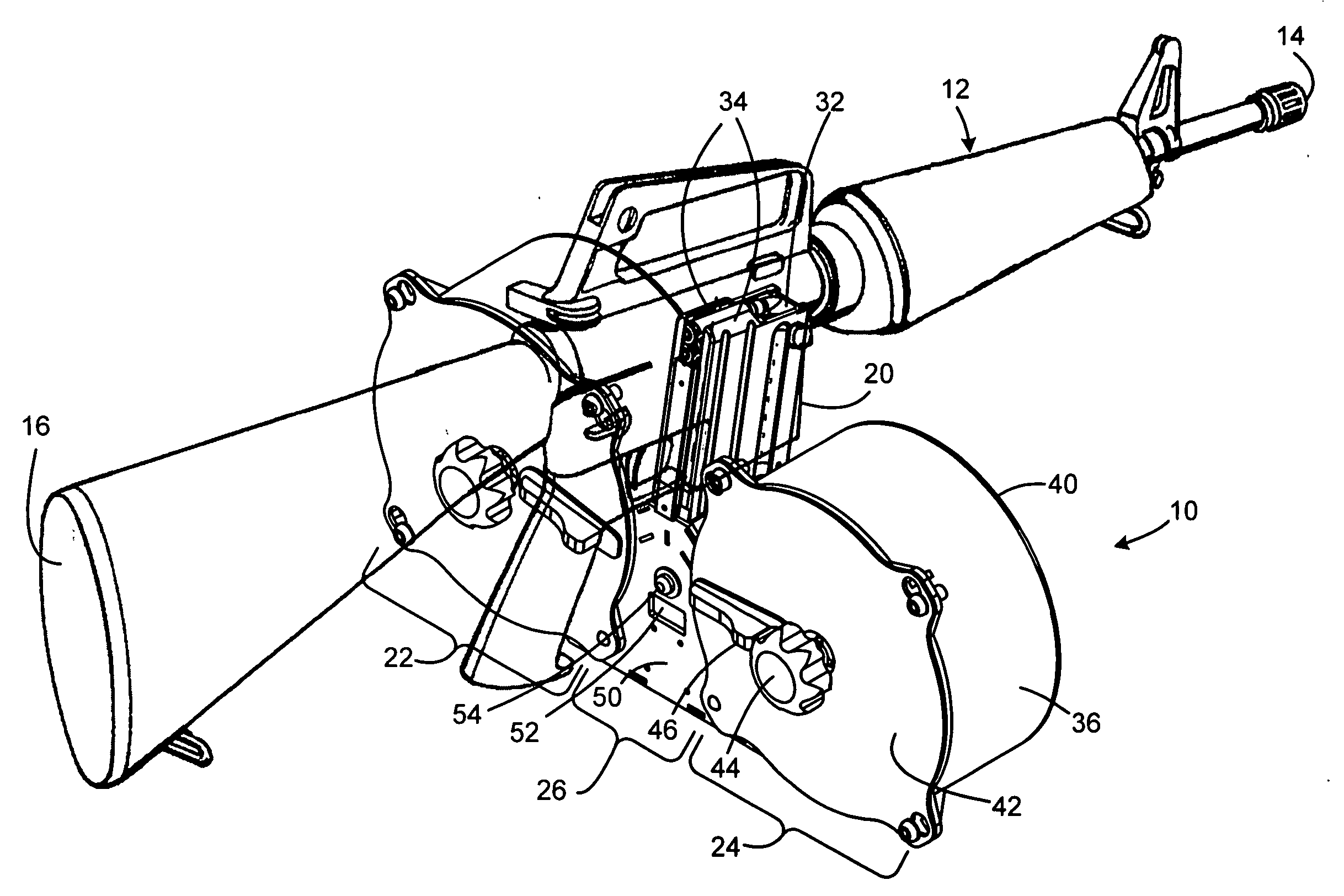

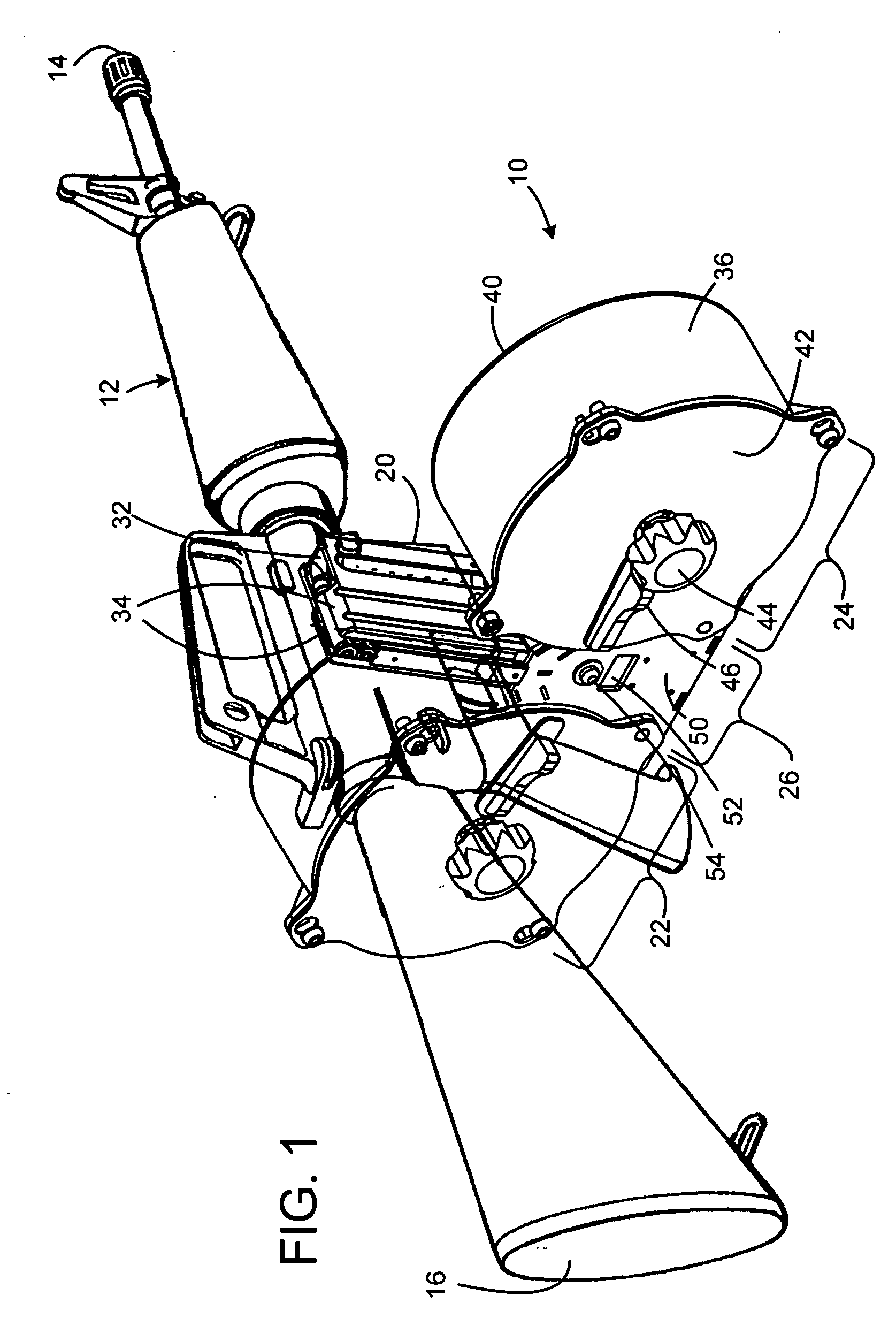

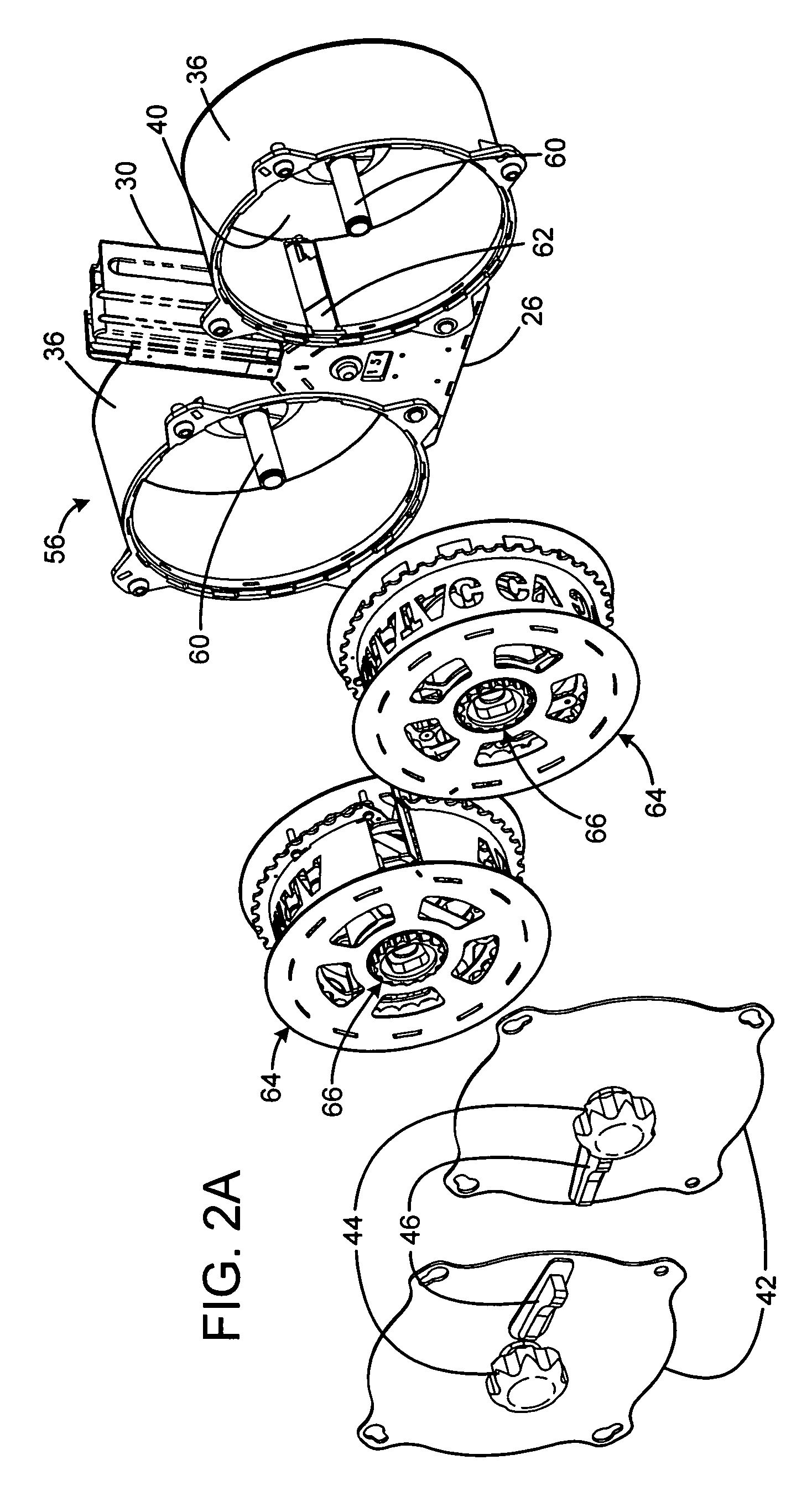

Drum magazine for firearm

ActiveUS20070107592A1Avoid small quantitiesSmall armBreech mechanismsAmmunition loadingEngineeringSprocket

A detachable magazine for storing and delivering ammunition to a firearm having a magazine well. The magazine has a body with a column adapted for insertion into the magazine well. The column has a passage for transmitting ammunition to the firearm. The body includes a drum housing defining a substantially cylindrical chamber communicating with the column passage. A first sprocket element is rotatably received in the chamber and has a serrated periphery, with each serration adapted to receive an ammunition cartridge. A second sprocket element is rotatably received in the chamber, and is concentric with the first sprocket element, having a serrated periphery with each serration adapted to receive an ammunition cartridge. A spring element is connected to at least one of the sprocket elements, and operates to rotatably bias the sprocket elements to transmit cartridges from the drum chamber to the column passage. The magazine may have a pair of drums, and the sprockets may be tapered, to facilitate feeding of tapered cartridges. The magazine may include a counter to indicate the quantity of ammunition consumed or remaining. The magazine may include the ability to power and de-power spring motor.

Owner:ARMATAC INDS

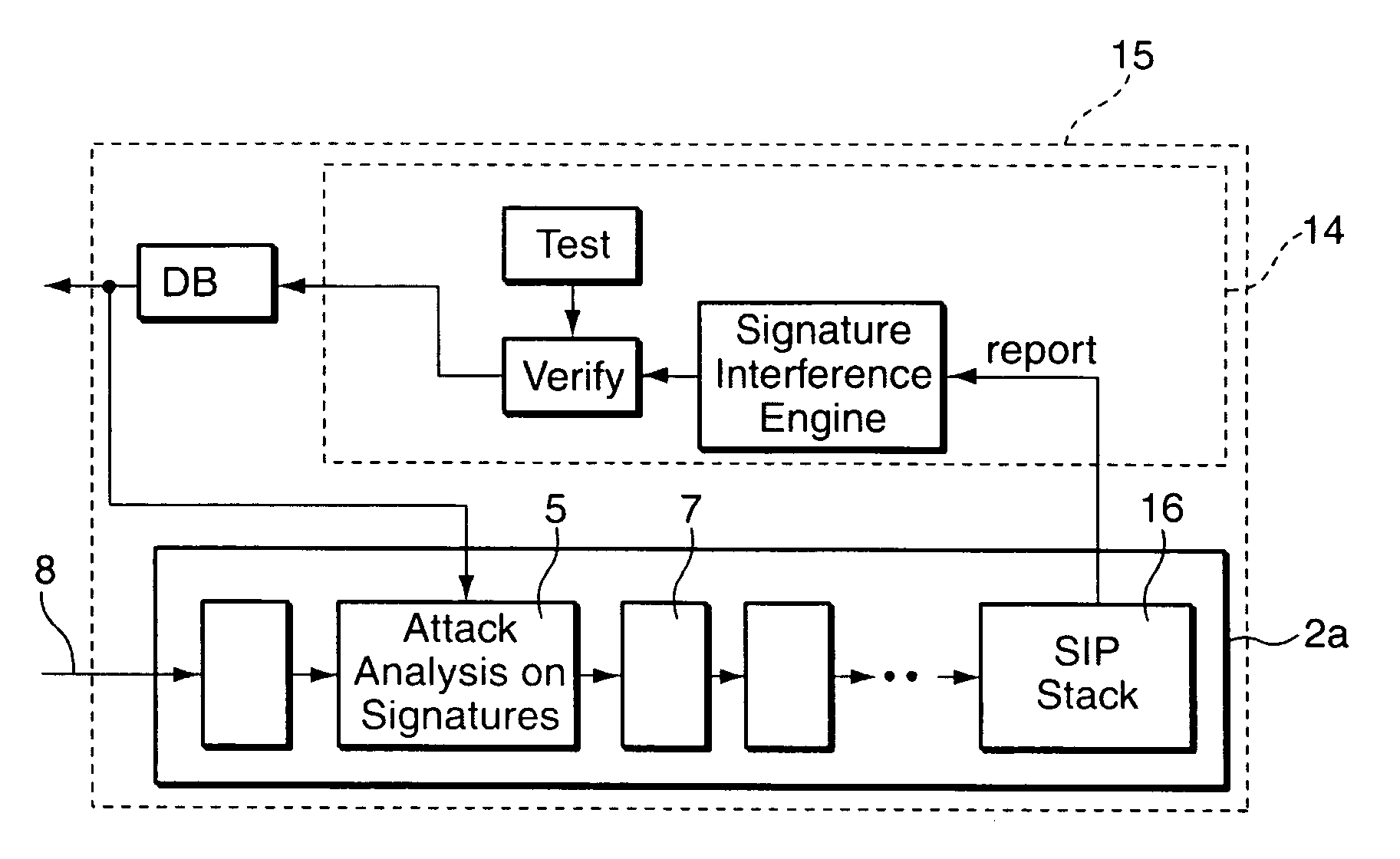

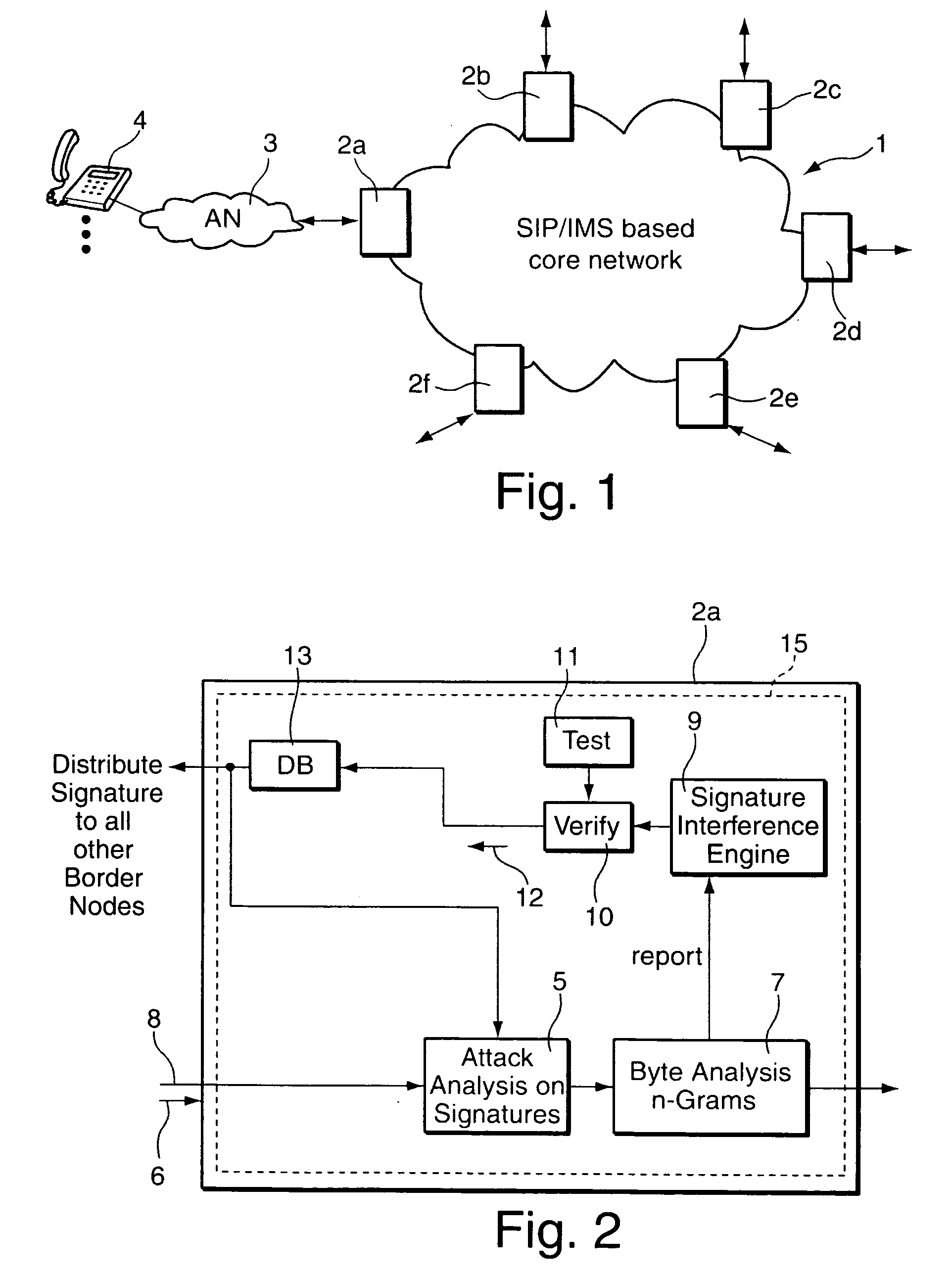

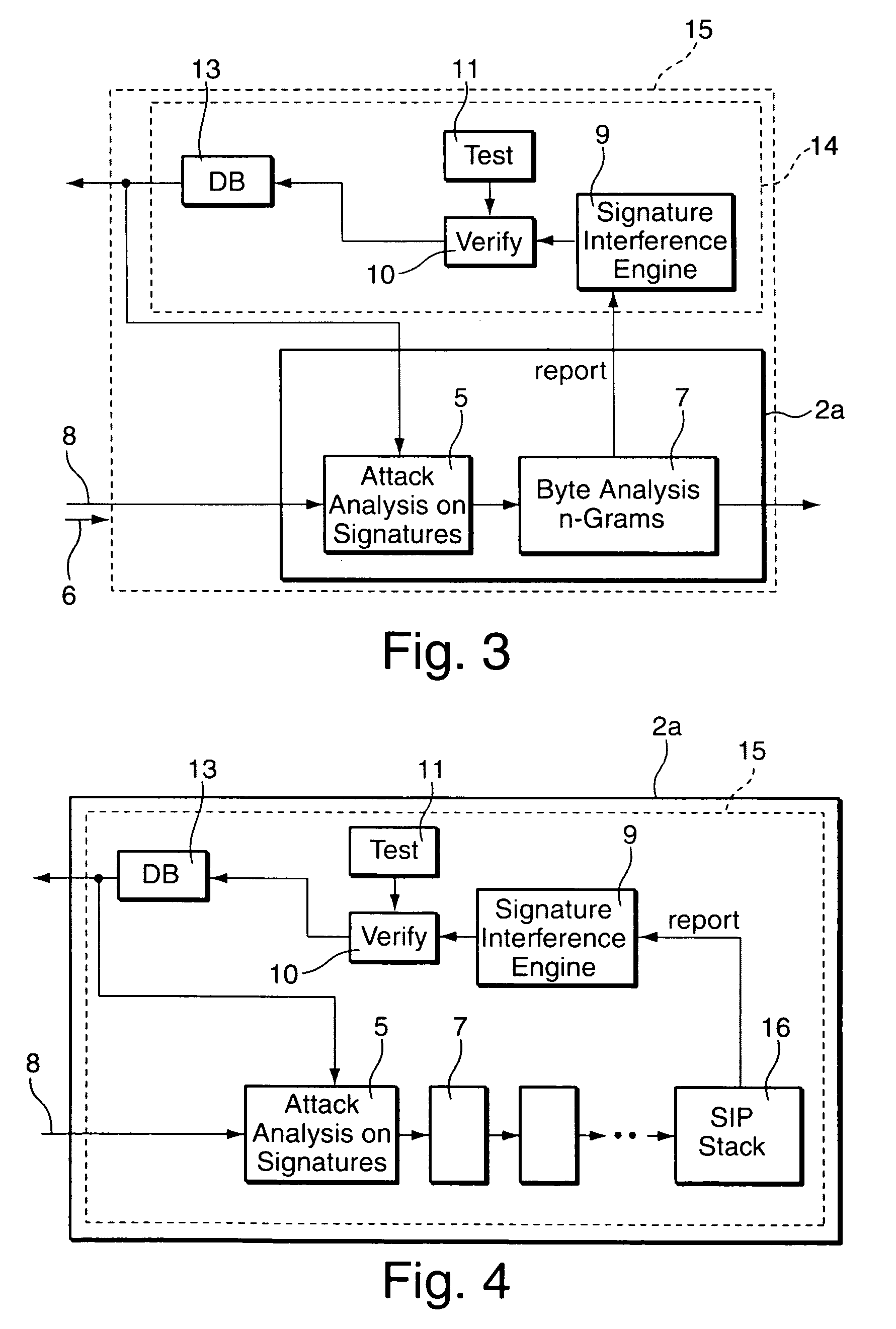

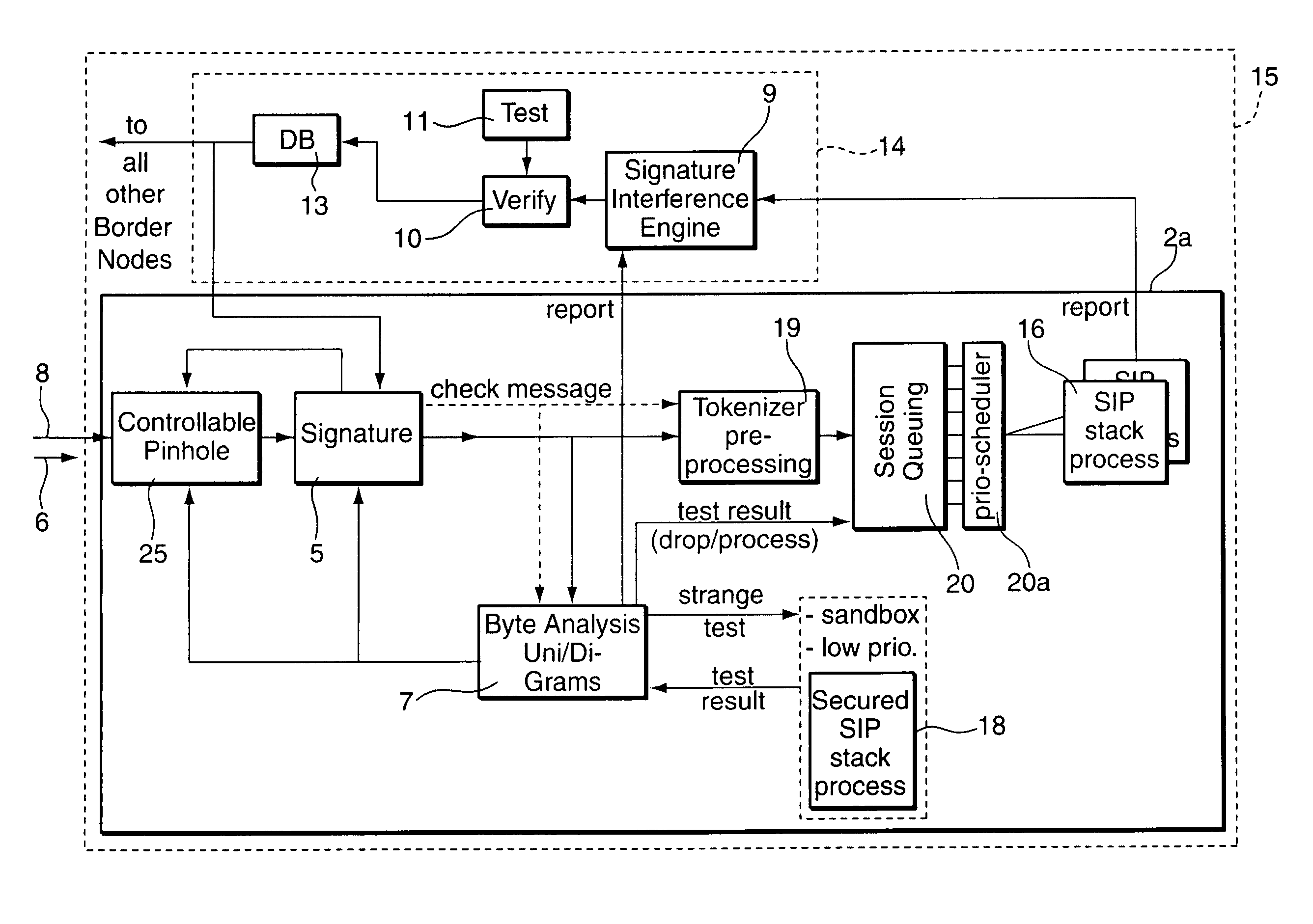

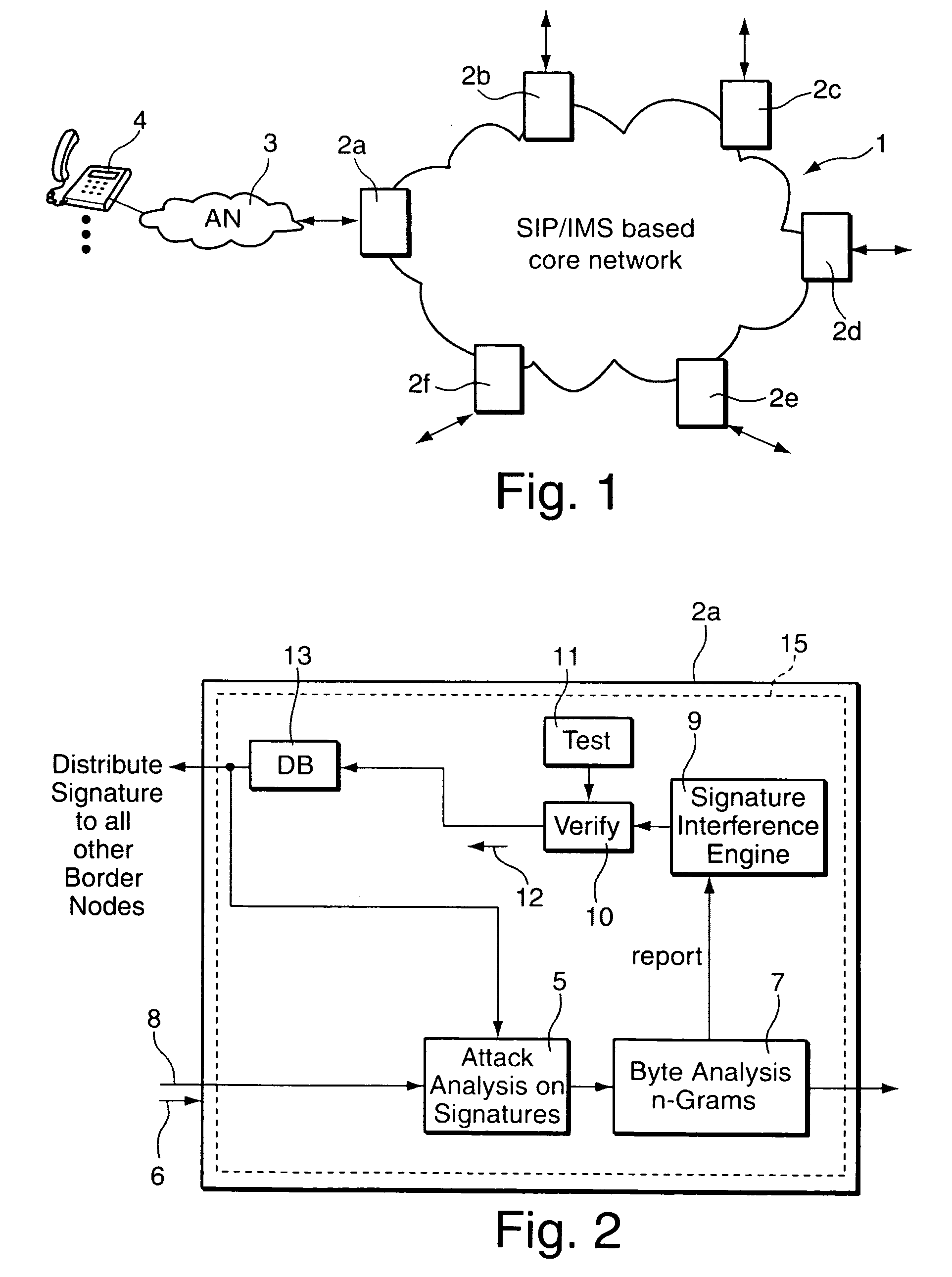

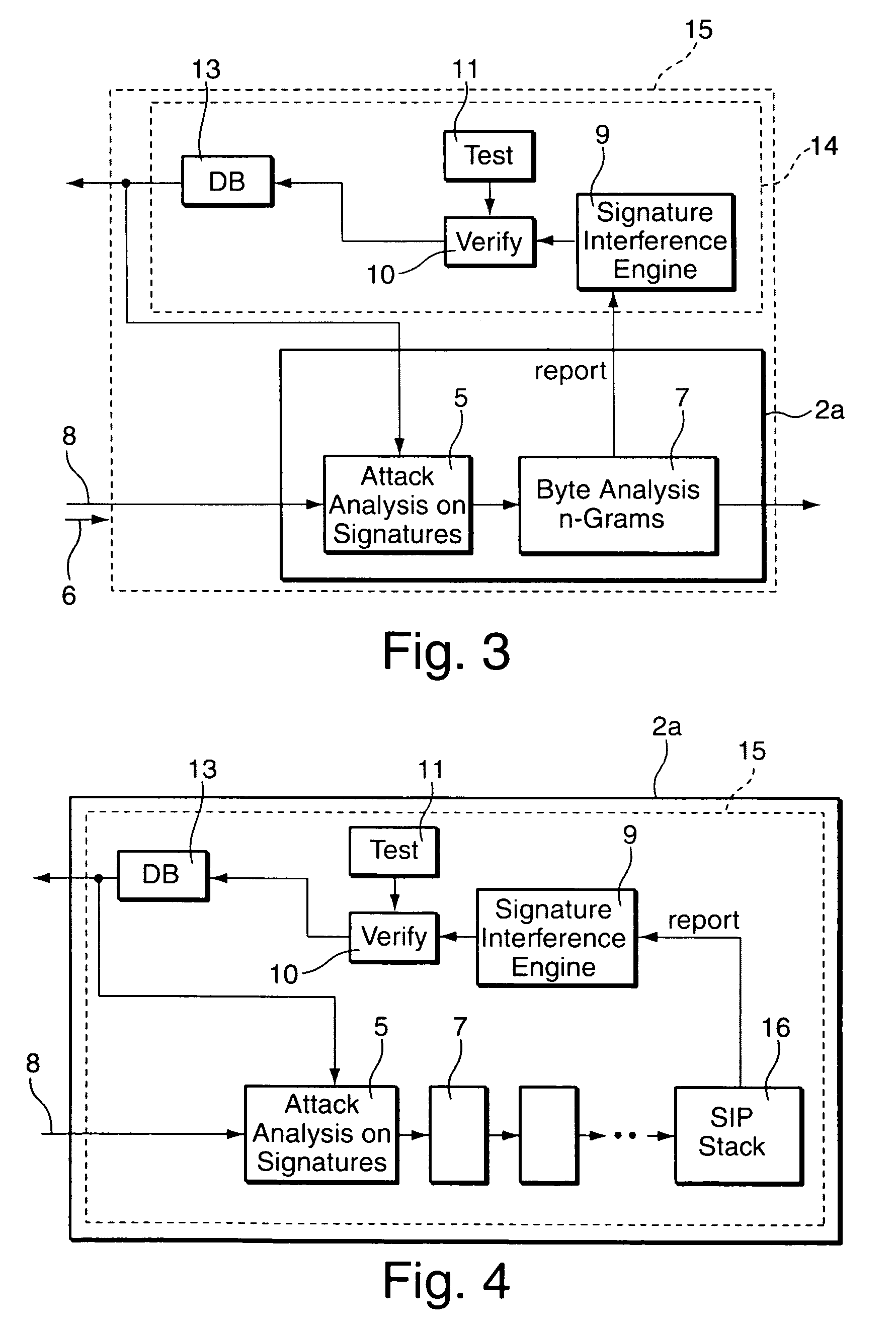

Attack protection for a packet-based network

ActiveUS20090265778A1Effective protectionCumbersome processMemory loss protectionError detection/correctionNetwork packetAnomaly detection

The invention relates to a protection unit (15) for protecting a packet-based network from attacks, comprising: a signature analyzer (5) for analyzing a packet stream (6) received in a security border node (2a) of the packet-based network (1) and for detecting attacks by comparing signatures of the packet stream (6) with a set of signatures of previously identified attacks, an anomaly detector, in particular a statistical analyzer (7), for detecting anomalies in the packet stream (6), and a signature interference unit (9) for updating the set of signatures when anomalies in the packet stream (6) are detected, the updated set of signatures (12) being subsequently used for performing the signature analysis. A distribution unit (13) distributes at least one signature of the updated set of signatures (12) to at least one further, preferably to each further security border node of the packet-based network (1). The invention also relates to a security border node comprising such a protection unit, to a network comprising at least two such protection units, and to a corresponding protection method.

Owner:ALCATEL LUCENT SAS

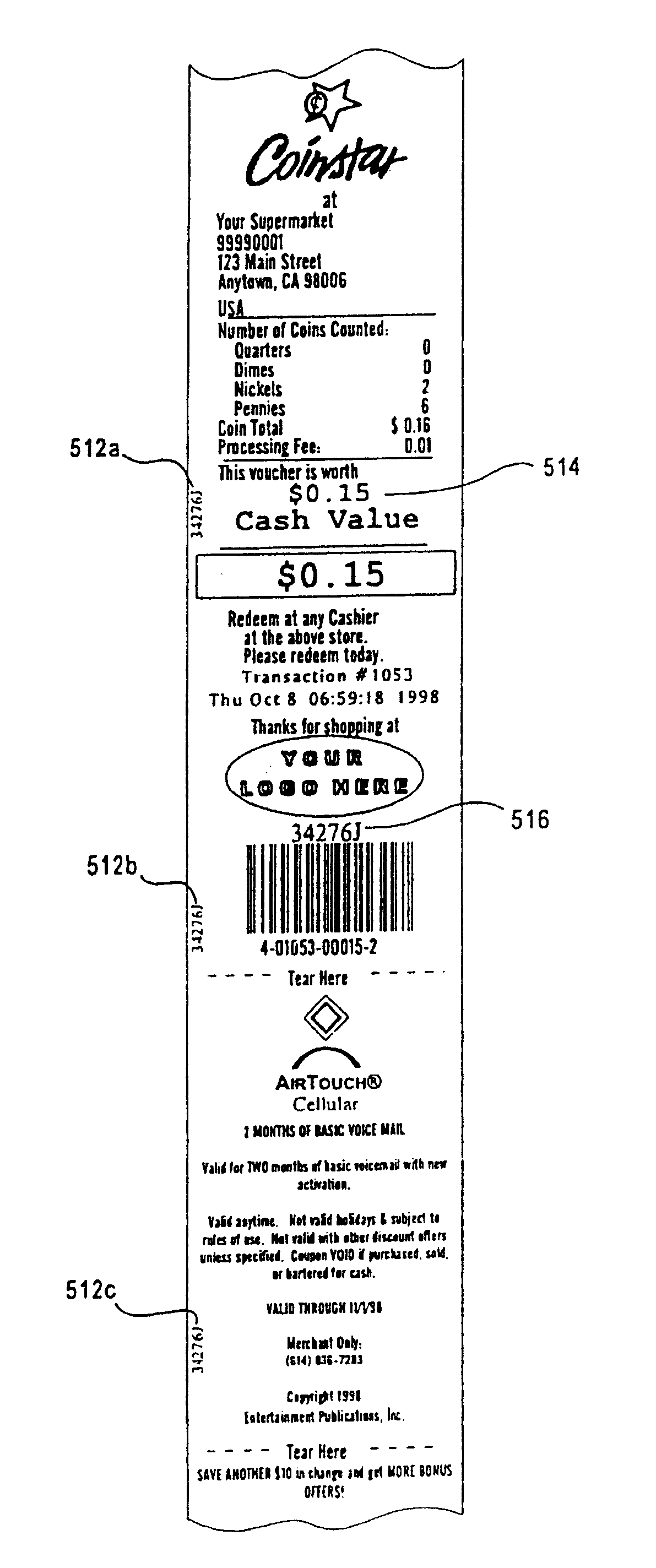

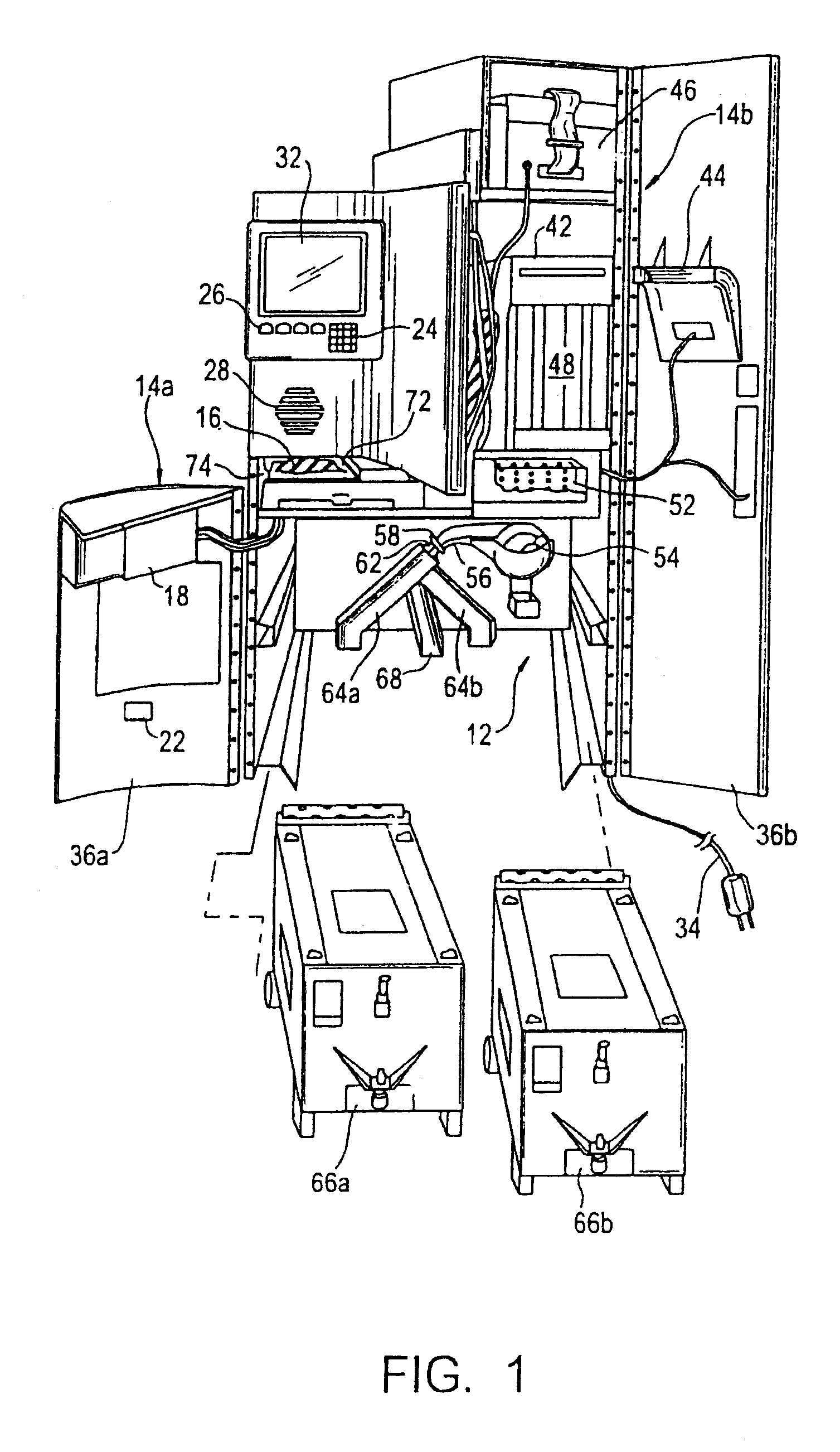

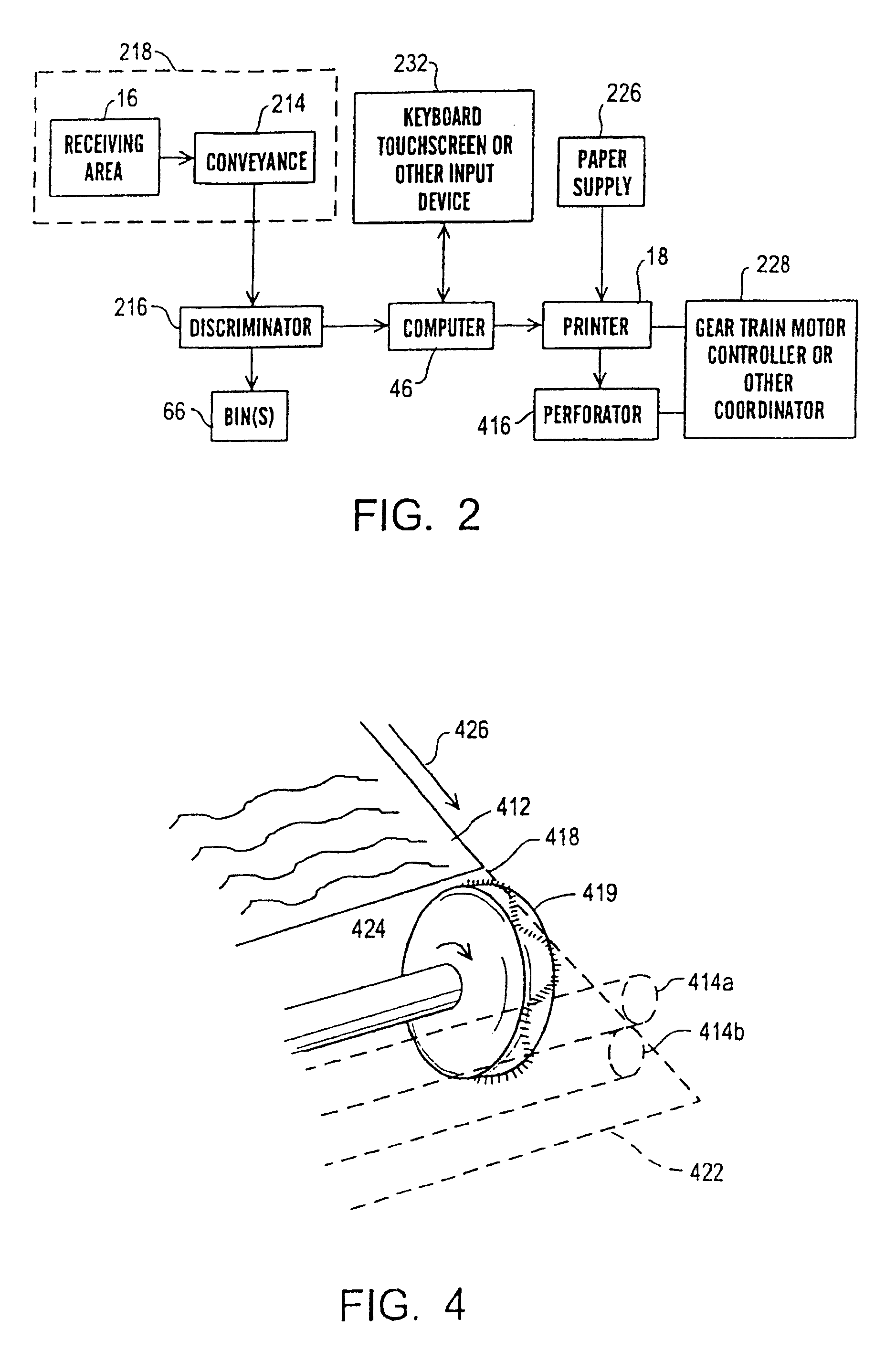

Coin-discriminator voucher anti-counterfeiting method and apparatus

InactiveUS7931304B2Reduce the burden onShorten the timeCredit registering devices actuationPayment architectureDiscriminatorVoucher

Vouchers and methods for providing vouchers configured to assist in distinguishing unauthorized duplicate or counterfeit vouchers are disclosed herein. In one embodiment, a voucher can include a substrate, a first indicia on the substrate, and a thermally responsive second indicia on the substrate. At least one of the first indicia and the second indicia can indicate a value of the voucher. A system which assists in detecting alteration of value documents or transmissions, such as a coin counter voucher is provided. Voucher information such as the voucher value is included in the voucher in an encrypted or otherwise modified form. When the voucher is presented for redemptions, the encrypted information is decrypted and compared to independently available voucher information. Failure of the information to match indicates that the voucher has been altered or should otherwise be further checked.

Owner:COINSTAR ASSET HLDG LLC

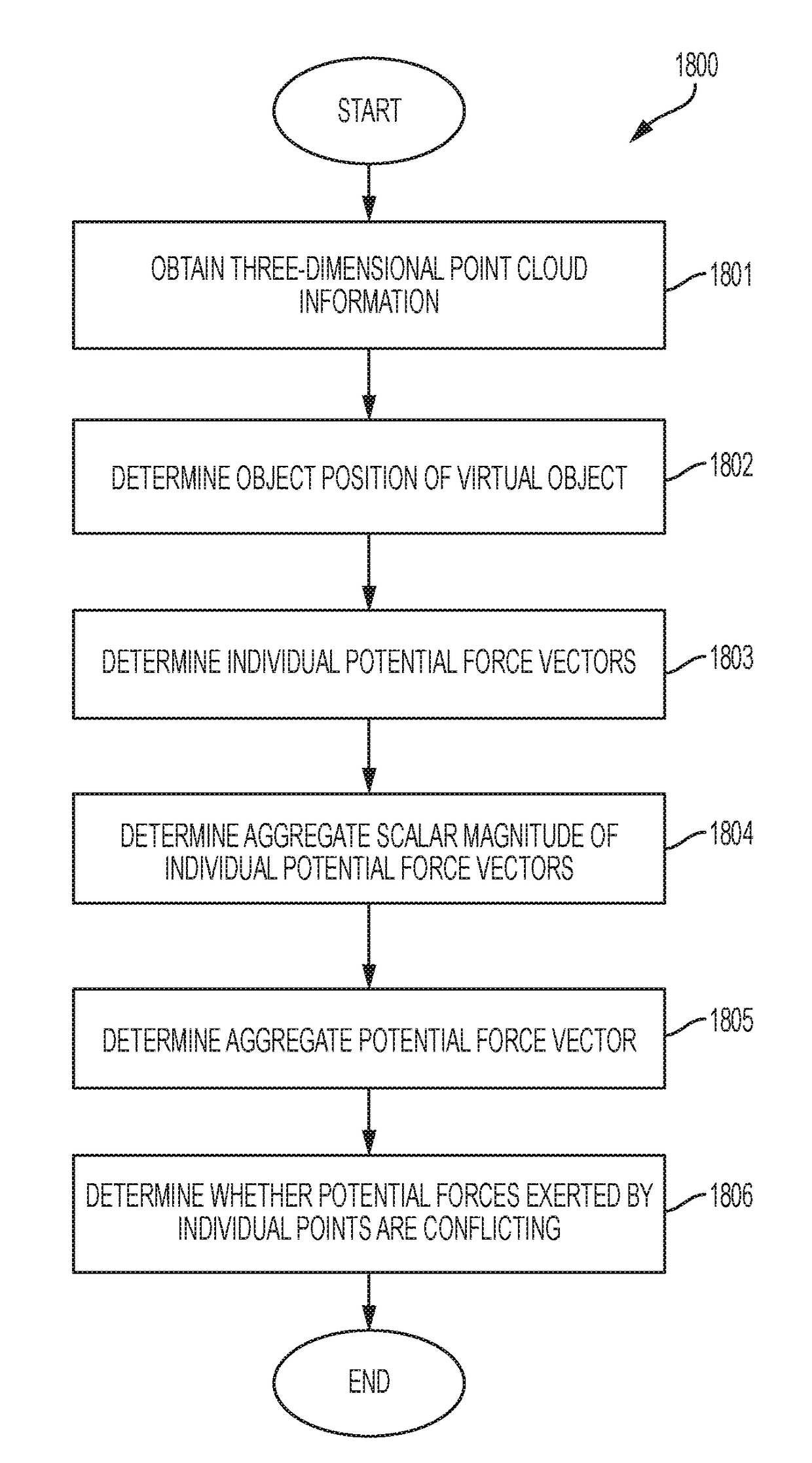

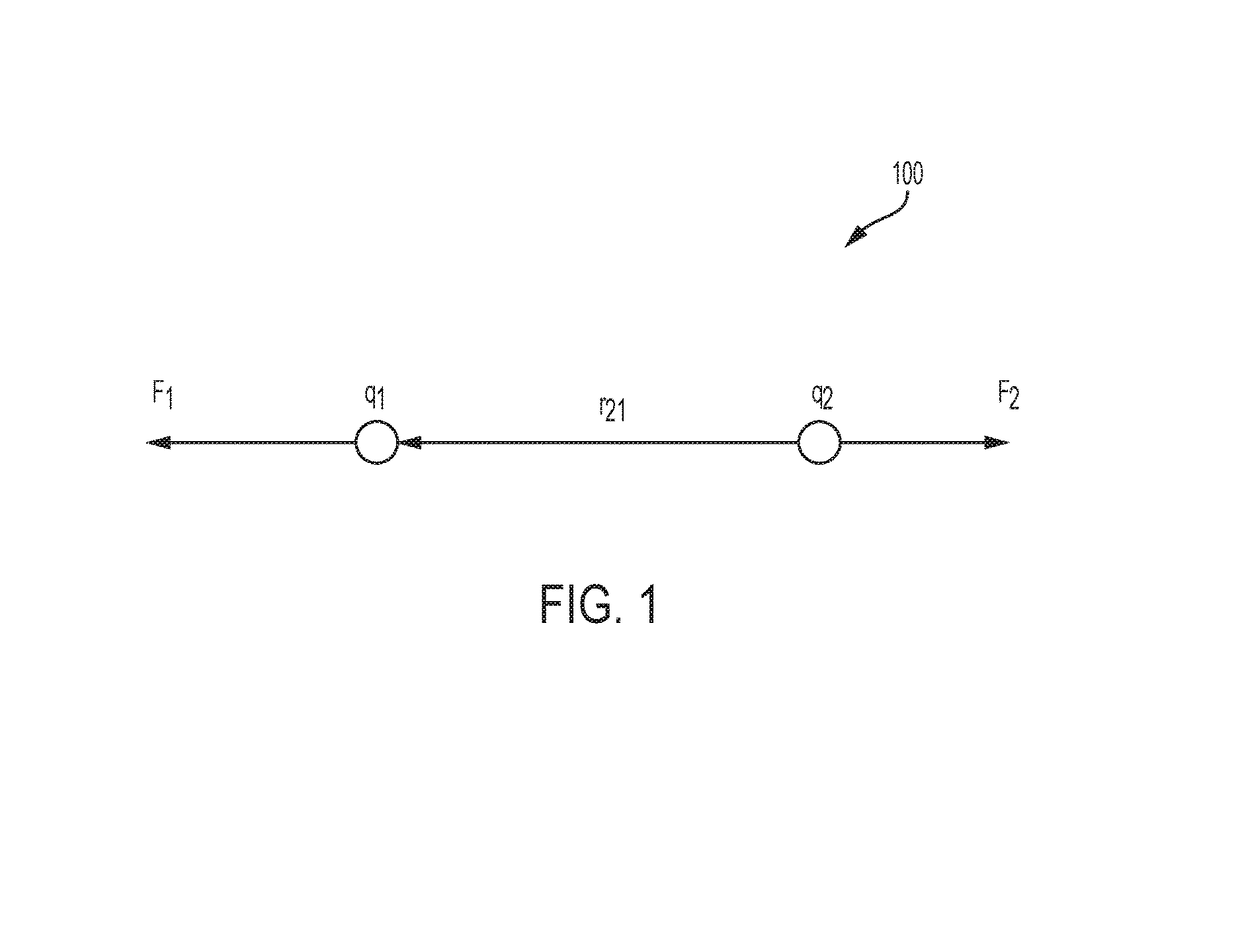

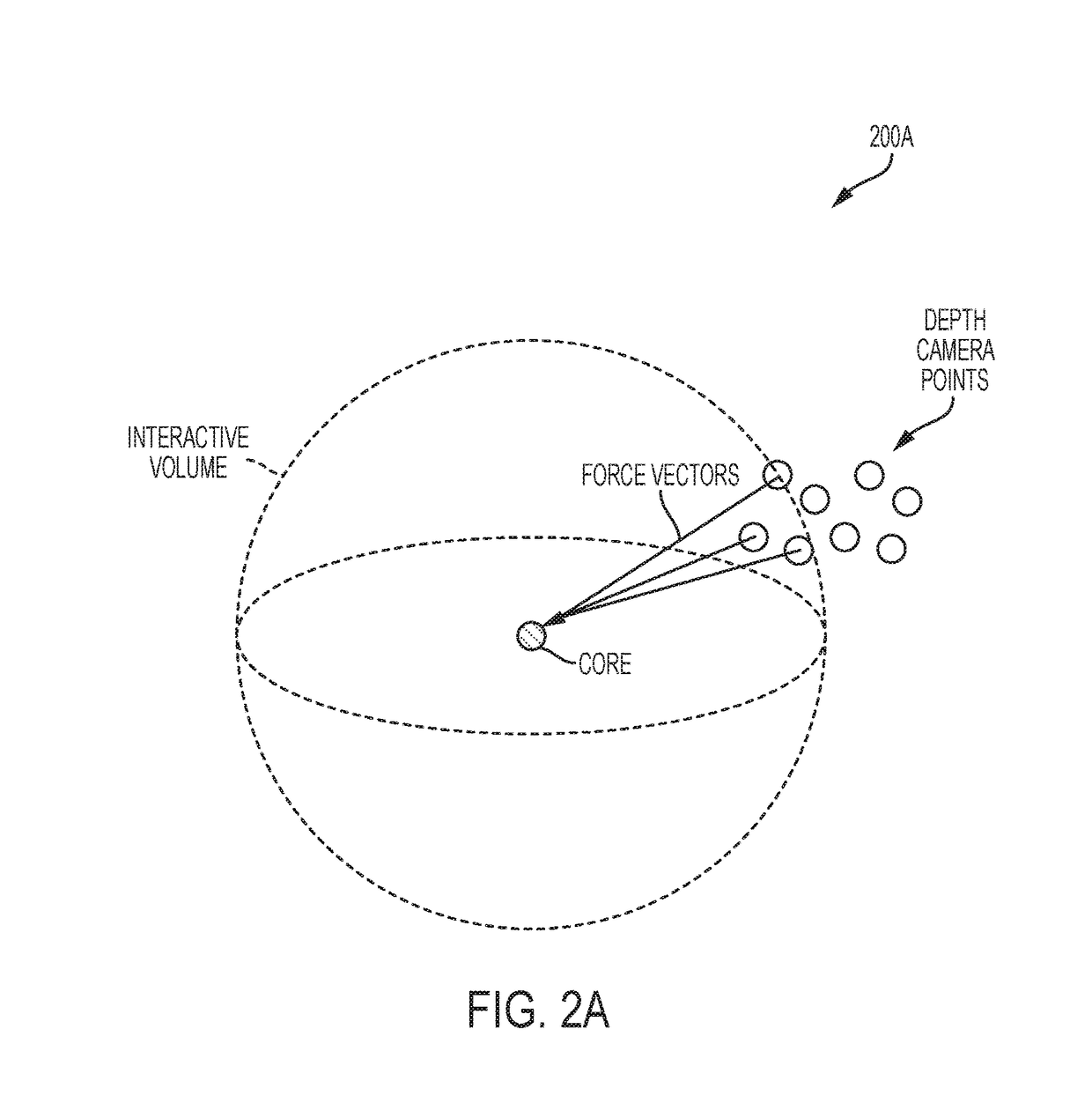

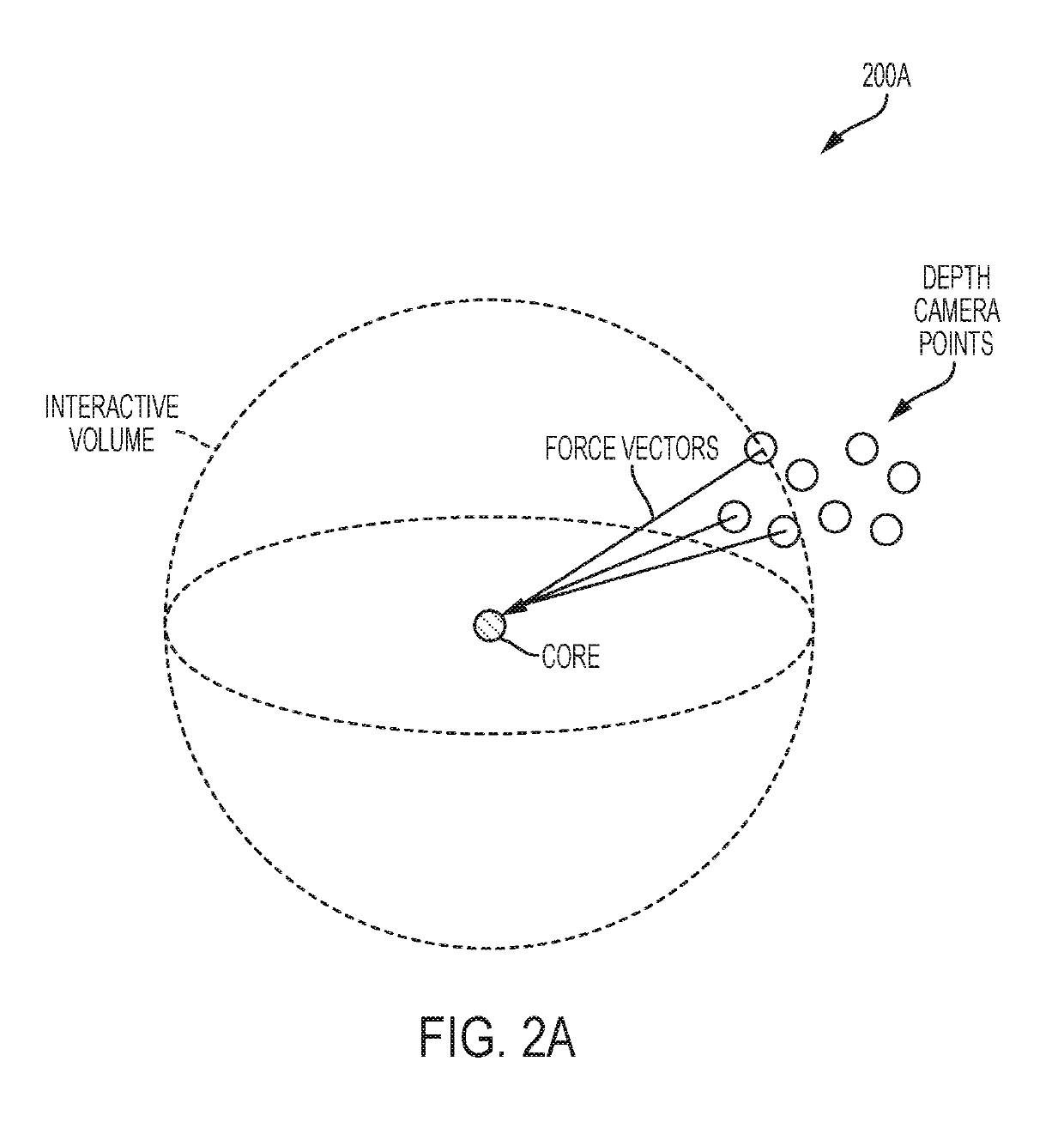

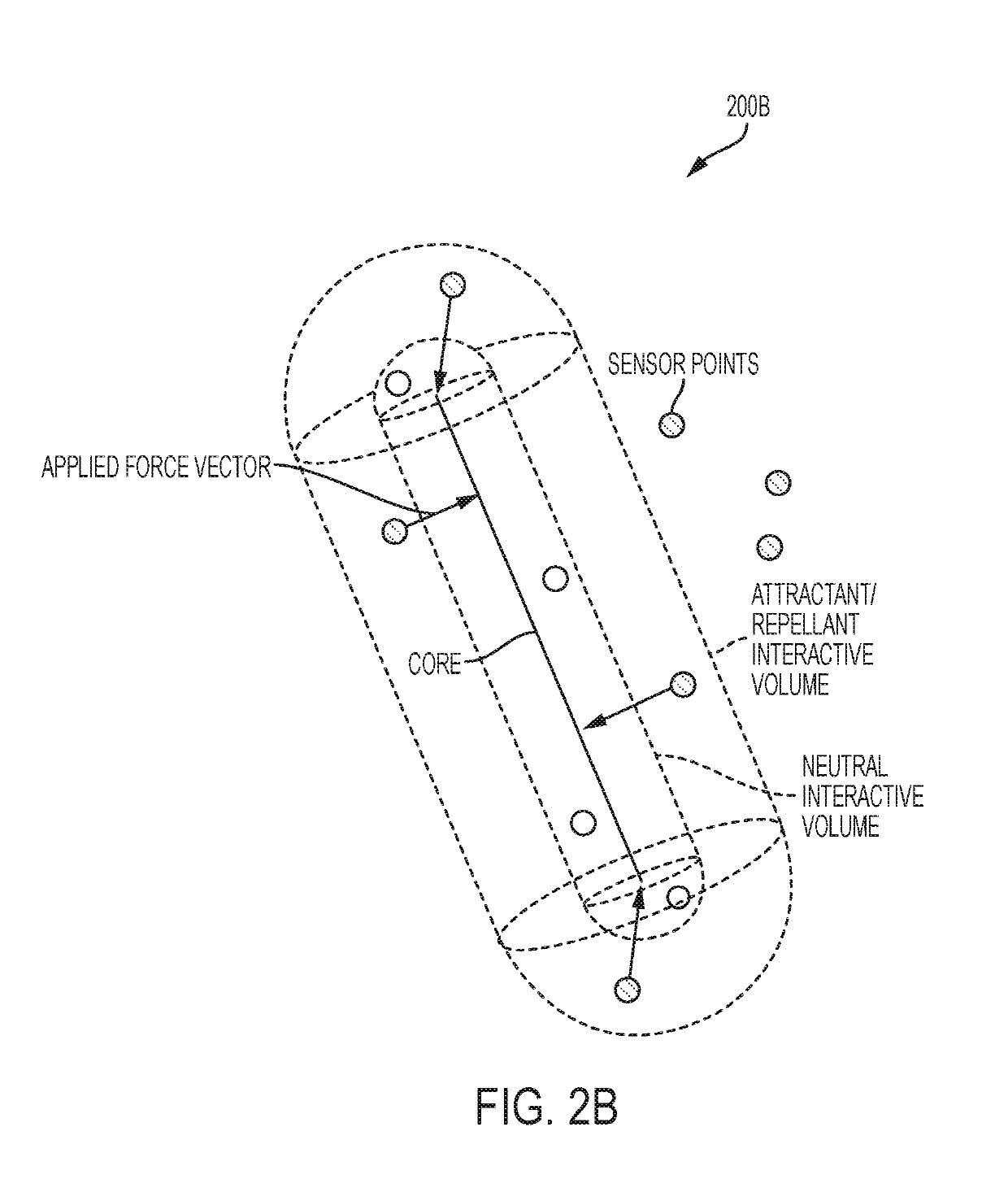

System and method for simulating user interaction with virtual objects in an interactive space

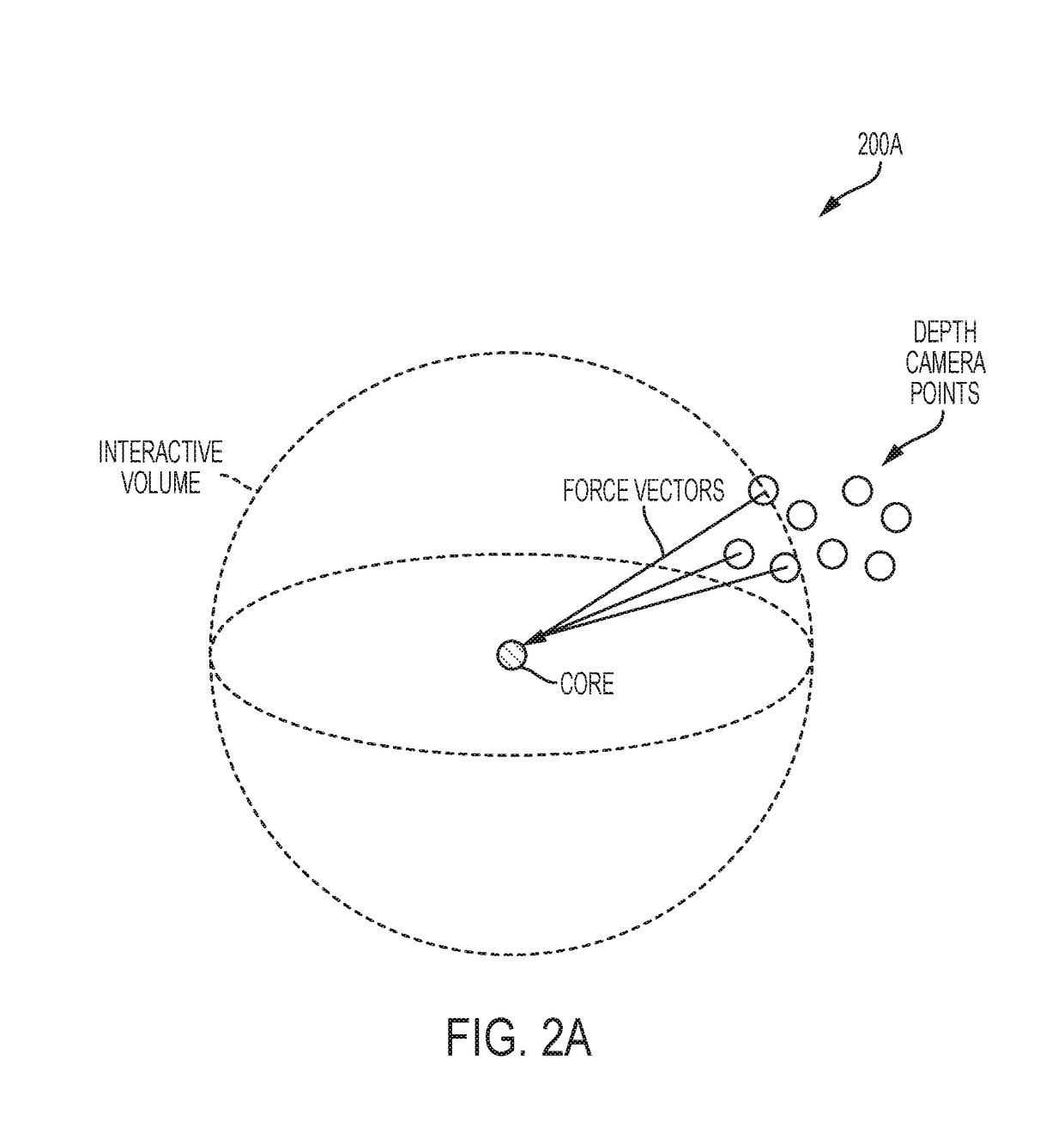

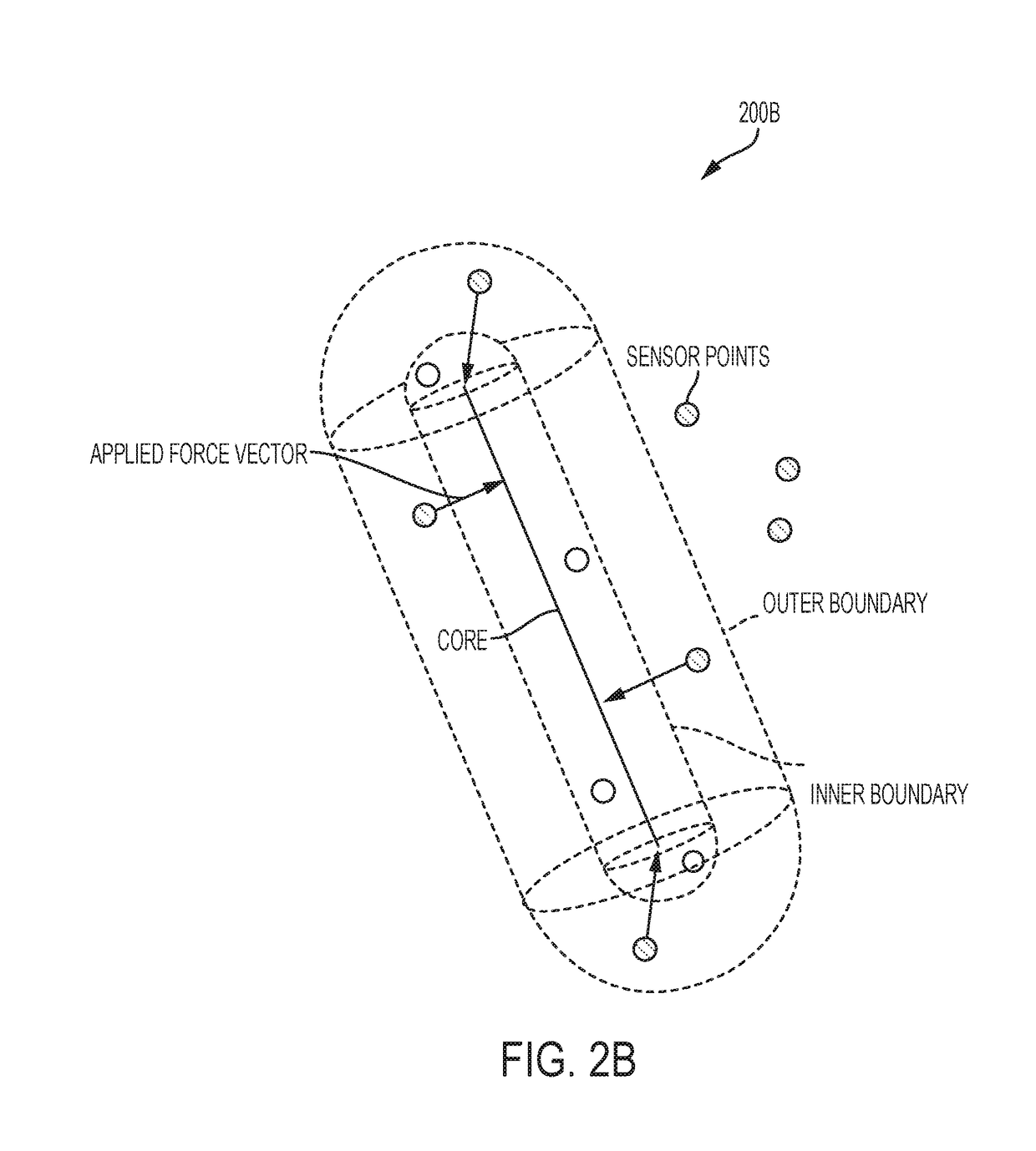

ActiveUS9928661B1Cumbersome processReduce noiseInput/output for user-computer interactionImage enhancementPoint cloudVolumetric imaging

Systems and methods for simulating user interaction with virtual objects in an augmented reality environment are provided. Three-dimensional point cloud information from a three-dimensional volumetric imaging sensor may be obtained. An object position of a virtual object may be determined. Individual potential force vectors for potential forces exerted on the virtual object may be determined. An individual potential force vector may be defined by one or more of a magnitude, a direction, and / or other information. An aggregate scalar magnitude of the individual potential force vectors may be determined. An aggregate potential force vector may be determined by aggregating the magnitudes and directions of the individual potential force vectors. It may be determined whether the potential forces exerted on the virtual object are conflicting.

Owner:META +1

Digital imbalance correction method and device in a receiver for multi-carrier applications

InactiveUS7376170B2Minimal complexityCumbersome processResonant long antennasInterconnection arrangementsTime domainPhase correction

Owner:NOKIA CORP

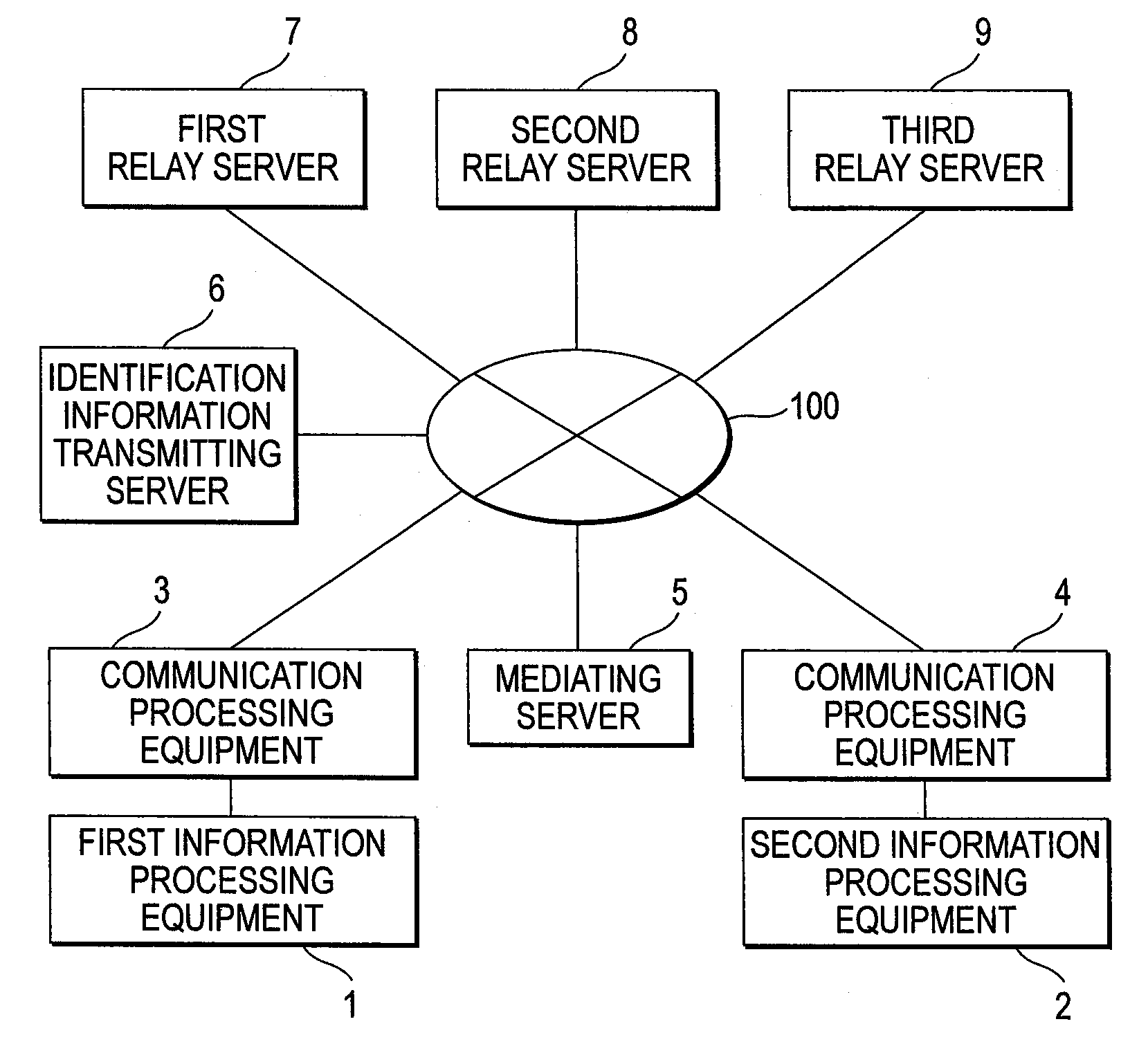

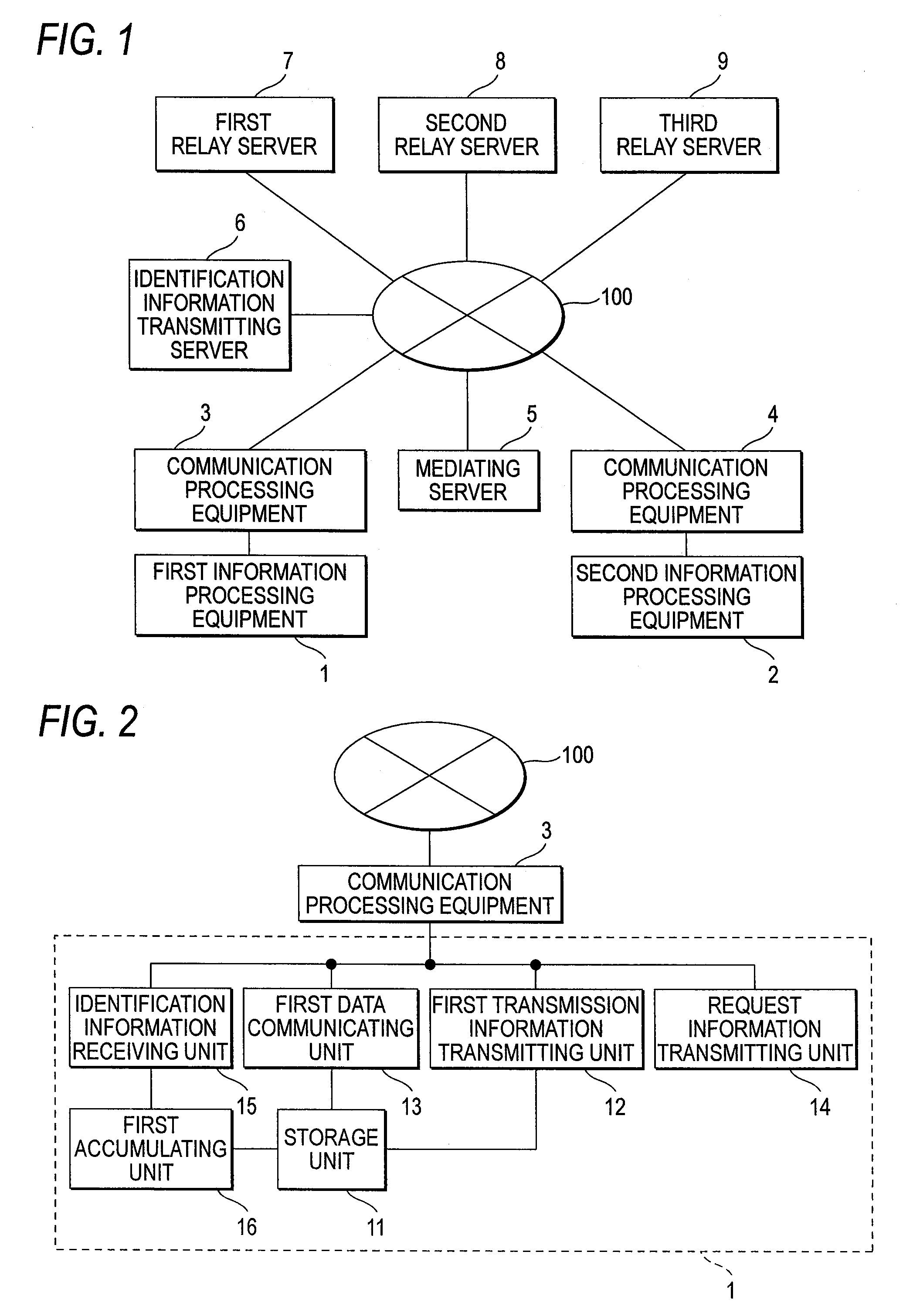

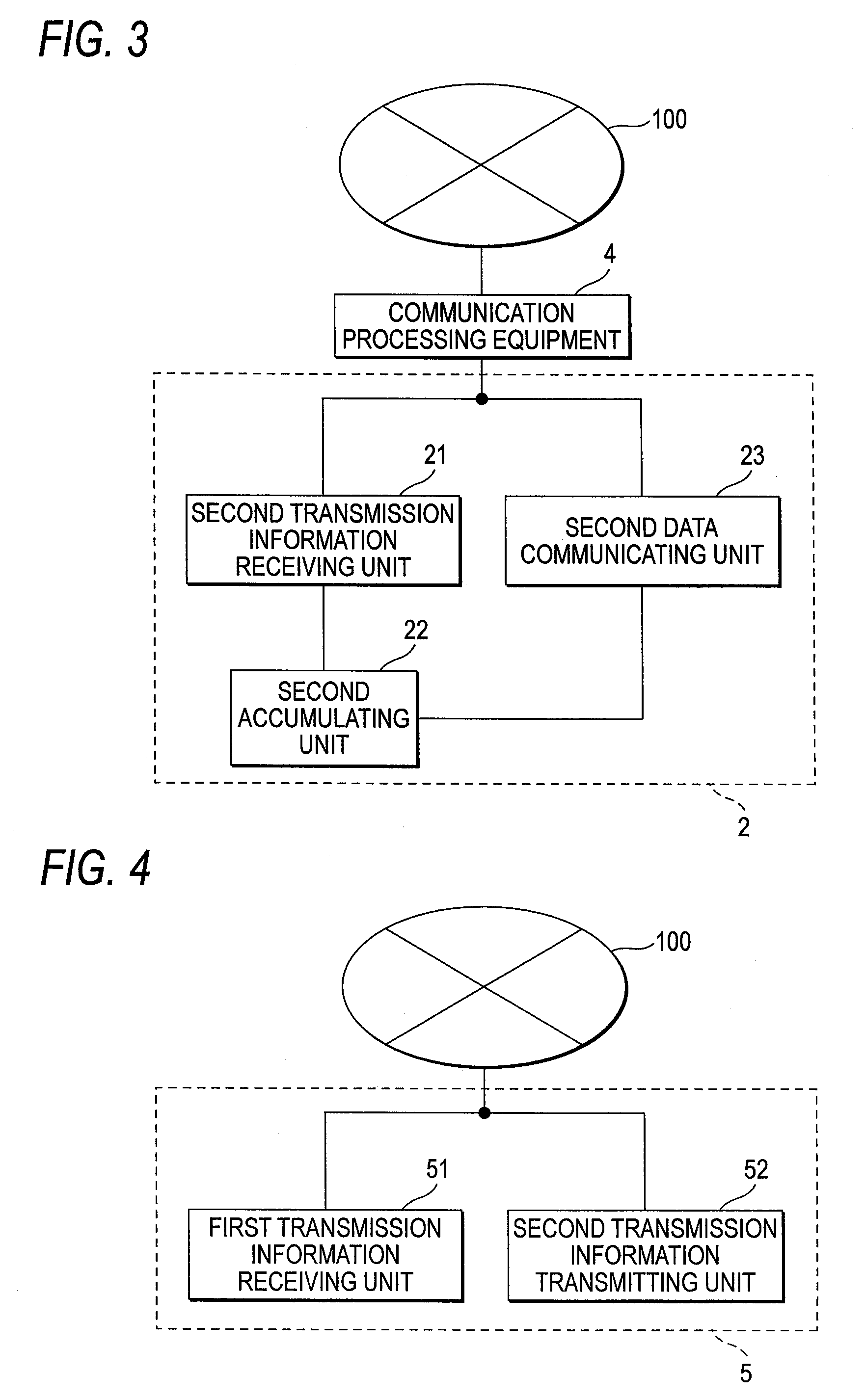

Communication system, information processor, intervening server, identification information transmitting server, communication method and program

ActiveUS20090073969A1Appropriately executedEasy to handleData switching by path configurationCommunications systemInformation processor

A first information processing equipment transmits, to a mediating server, the first transmission information which is the information containing the relay server identification information for identifying the relay server employed in the data relay between information processing equipments, and executes the data relay with the second information processing equipment through the relay server identified by the relay server identification information. The mediating server receives the first transmission information and transmits, to a second information processing equipment, the second transmission information which is the information containing the relay server identification information contained in the first transmission information. The second information processing equipment receives the second transmission information and executes the data relay with the first information processing equipment through the relay server identified by the relay server identification information contained in the second transmission information.

Owner:PANASONIC CORP

Methods and apparatus for accelerating content authored for multiple devices

ActiveUS9817916B2Reduce deliveryCumbersome processMultiple digital computer combinationsApparatus for meter-controlled dispensingProxy serverWeb content

Owner:AKAMAI TECH INC

Cecropin A-magainin hybrid gene engineering bactericidal peptide

InactiveCN1896107AReduce manufacturing costLow priceAntibacterial agentsPeptide/protein ingredientsCrystallographyYeast

An eka-cecropinA-magainin heterozygous gene engineering antibacterial peptide is prepared by adopting No.1-7 amino acid residue on N end of cecropinA CA and No.2-12 amino acid residue on N end of magainin M, design synthesizing heterozygous peptide CA(1-7)-M(2-12) gene by codon, connecting with carrier pPICZ alpha-A, mutating by point mutation technology to obtain mutant pPICZ alpha-CA-Mu-1, pPICZ alpha-CA-Mu-2 and pPICZ alpha-CA-Mu-3, converting SMD1168, and expressing CecA-Mag heterozygous antibacterial peptide to make into use under alcohol hydrogenase starter regulation.

Owner:NANJING AGRICULTURAL UNIVERSITY

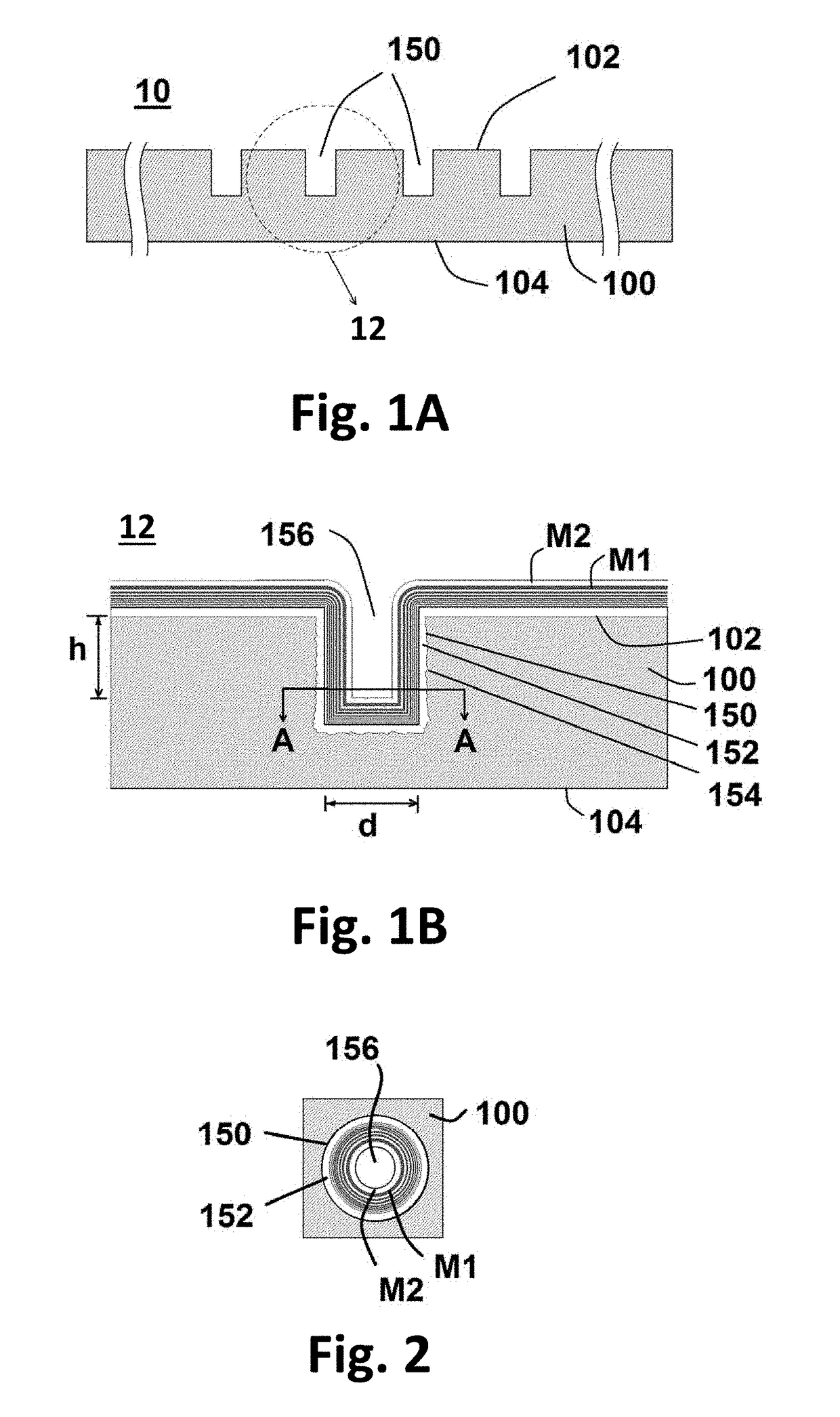

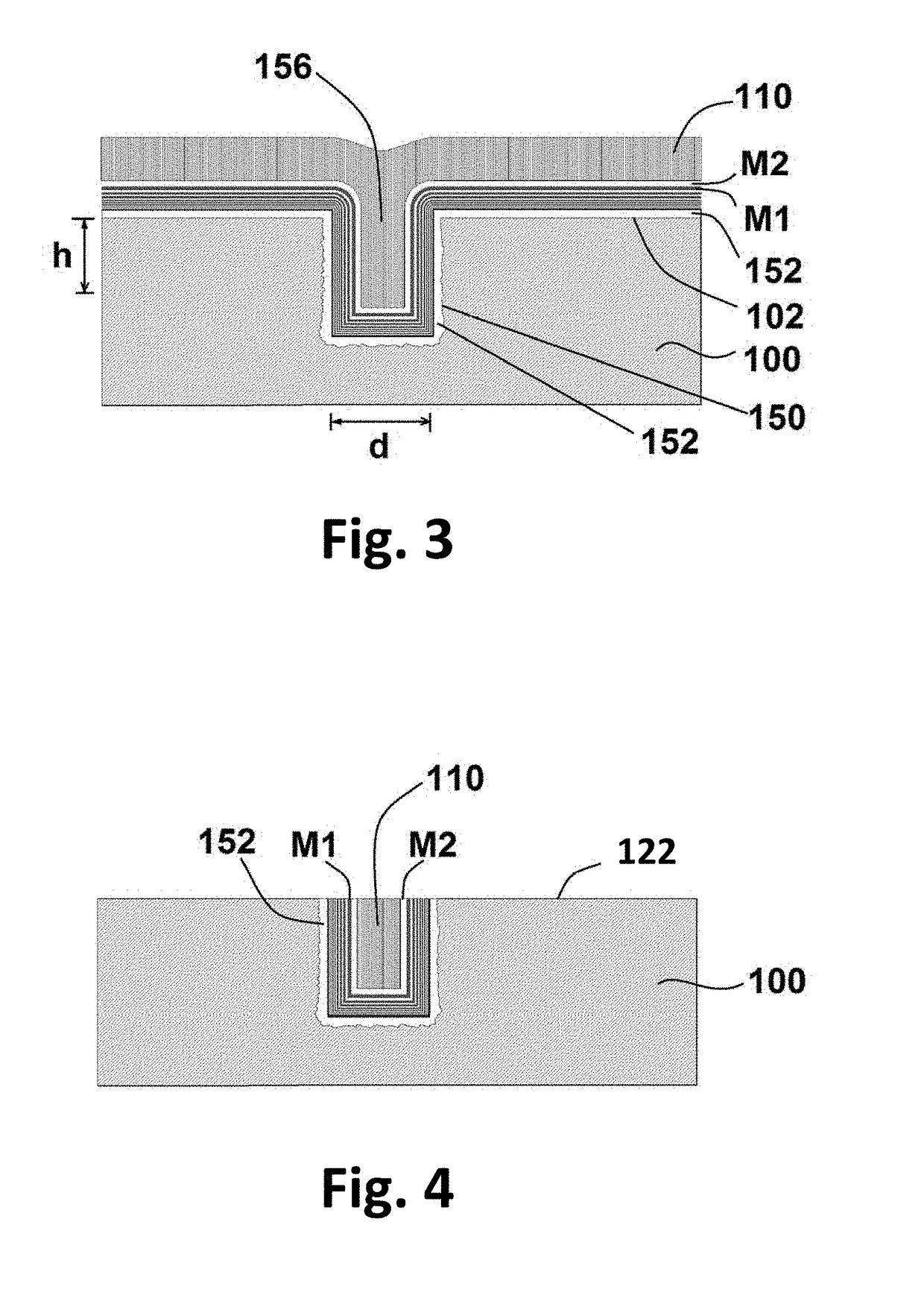

Batch-processing method for super-high aspect ratio diffractive optics

ActiveUS20170256330A1Well representedConfers robustnessHandling using diffraction/refraction/reflectionVacuum evaporation coatingOptical propertyPlanar substrate

A method for fabrication of diffractive optics by batch processing is disclosed, having applicability to high resolution ultra-high aspect ratio Fresnel Zone Plates for focusing of X-rays or gamma-rays having energies up to hundreds of keV. An array of precursor forms is etched into a planar substrate. Sidewalls of the forms are smoothed to a required surface roughness. A sequence of alternating layers of different complex refractive index, for binary or higher order diffractive optics, are deposited on the precursor forms by atomic layer deposition (ALD), to provide diffractive line patterns. Thinnest layers may have nanometer thicknesses. After front surface planarization and thinning of the substrate to expose first and second surfaces of the diffractive line patterns of the diffractive optic, the height h in the propagation direction provides a designed absorption difference and / or phase shift difference between adjacent diffractive lines. Optionally, post-processing enhances mechanical, thermal, electrical and optical properties.

Owner:ALCORIX CO

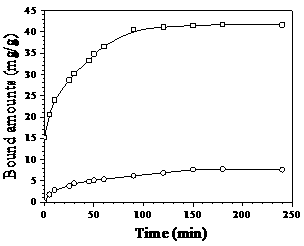

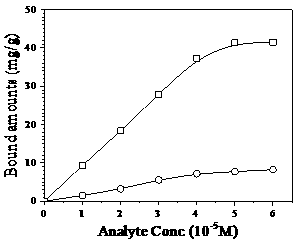

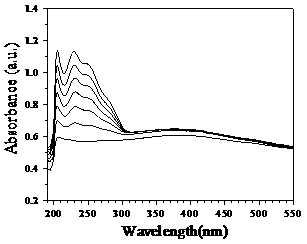

Preparation method of Fe3O4@PEG@SiO2 artificial antibody for detecting thifensulfuron methyl

ActiveCN106970215AImprove adsorption capacityHigh magnetizationOther chemical processesColor/spectral properties measurementsPolyethylene glycolAbsorption rate

A preparation method of Fe3O4@PEG@SiO2 artificial antibody for detecting thifensulfuron methyl comprises modifying the surface of Fe3O4 magnetic nanoparticles with polyethylene glycol 2000, coating the surface with SiO2 shell layer to form a core-shell-shell structure, diluting marker molecules in the SiO2 shell layer to form specific recognition site holes complementary with marker molecular structure, size and functionality so as to arrive at molecular selective recognition and detection for target analyses. The preparation method of the artificial antibody comprises the steps of first, preparing Fe3O4 magnetic nanoparticles, and modifying their surface with polyethylene glycol; second, adding the target molecule thifensulfuron methyl, a crosslinking agent and a catalyst, and hydrolyzing to obtain Fe3O4@PEG@SiO2 particles with surface-marked thifensulfuron methyl; third, diluting template molecule with a mixed solution of acetic acid and acetone having a volume ratio of 1:4 to obtain the Fe3O4@PEG@SiO2 artificial antibody with selective recognition marker molecules, the antibody having maximum saturated binding capacity of 41.28 mg / g for thifensulfuron methyl, the absorption rate reaches 0.45 mg / g.min within first 30 min which is 5.34 times and 3.46 times that of a non-marking method.

Owner:HEFEI UNIV

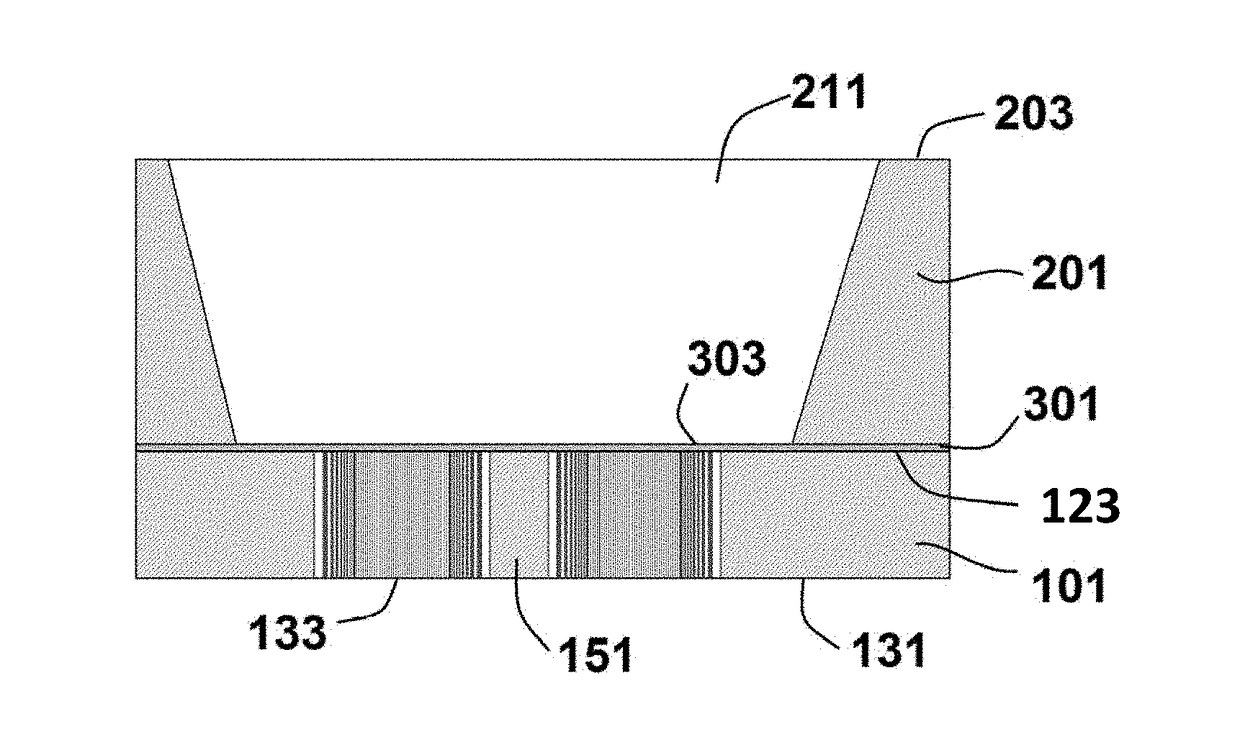

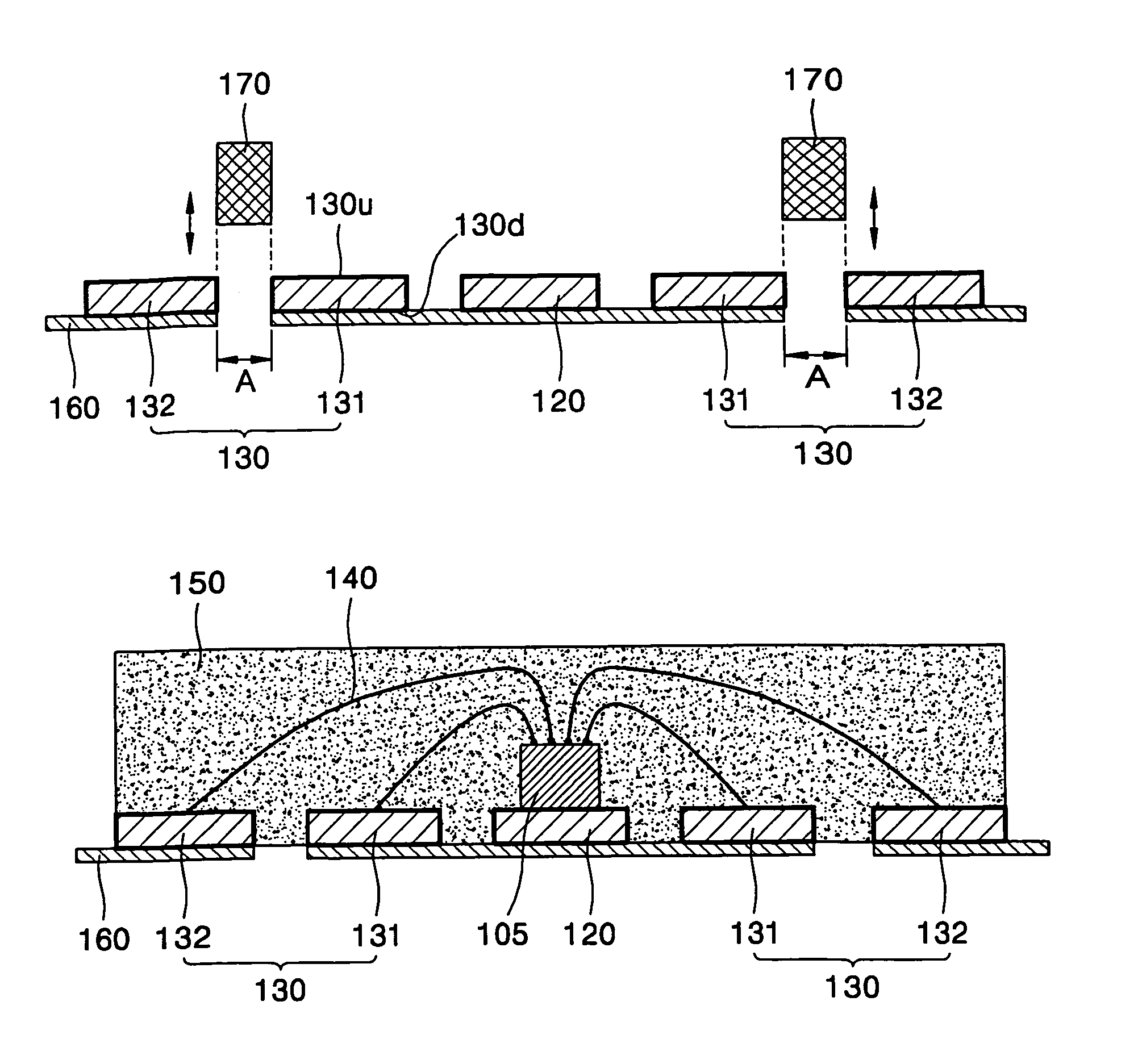

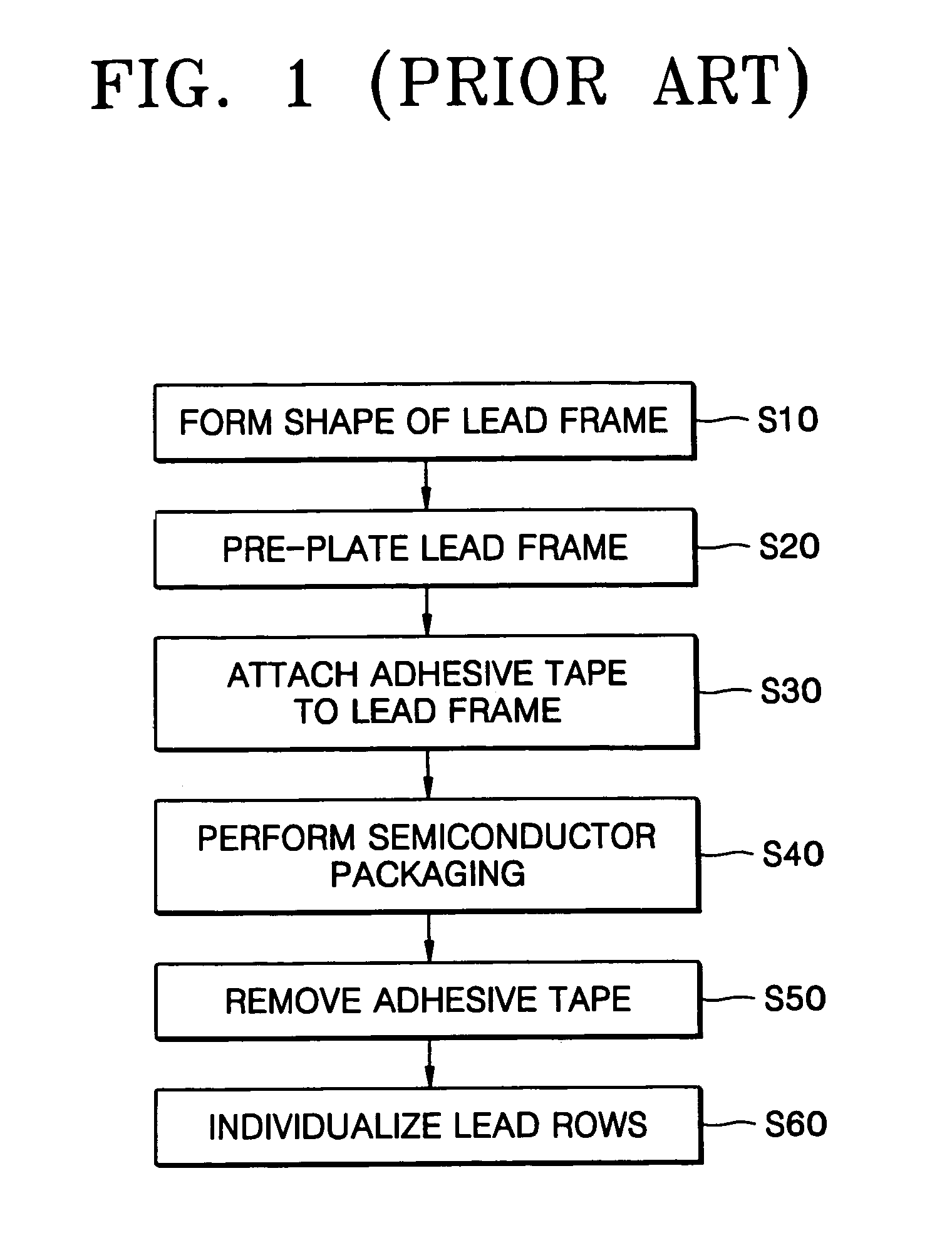

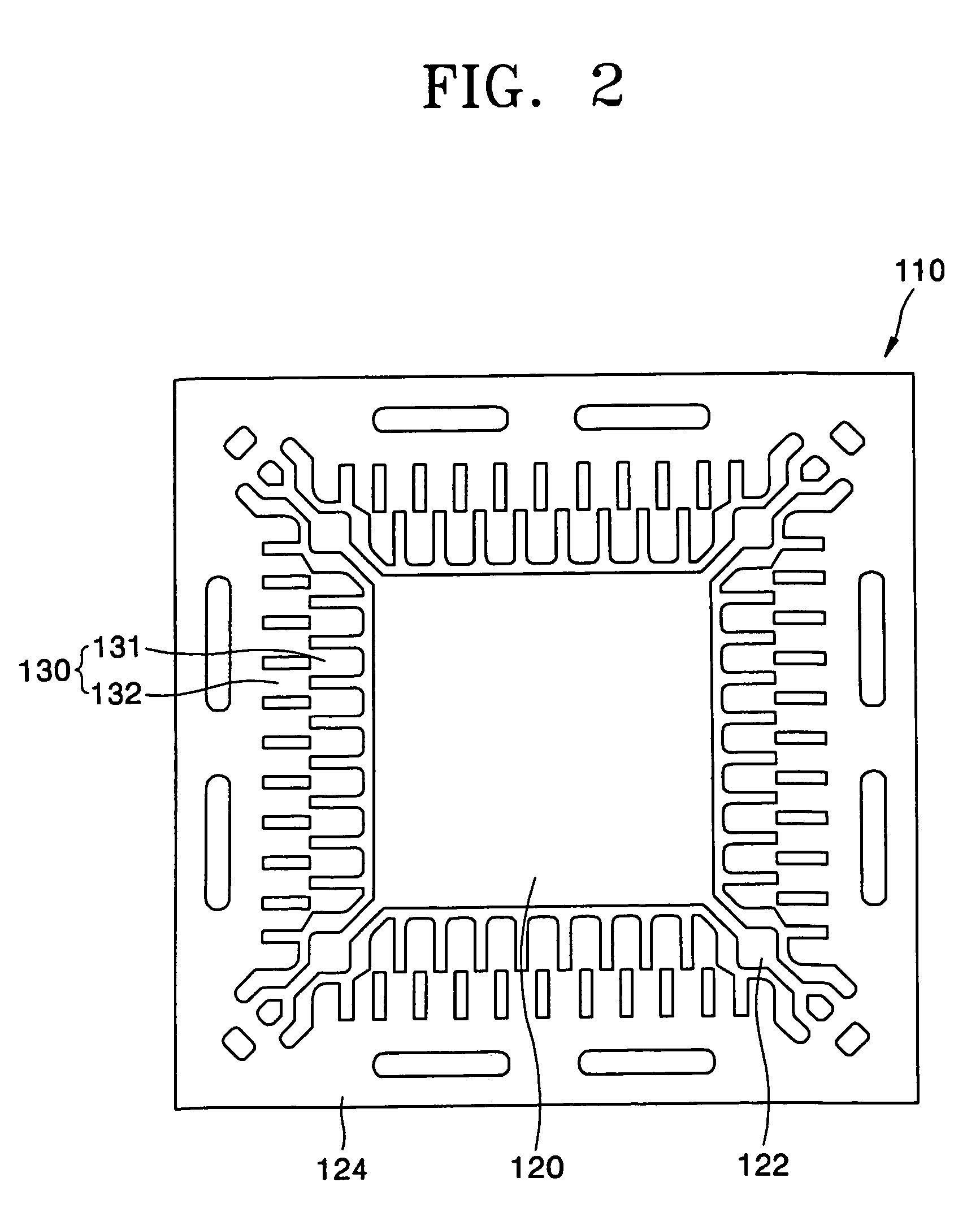

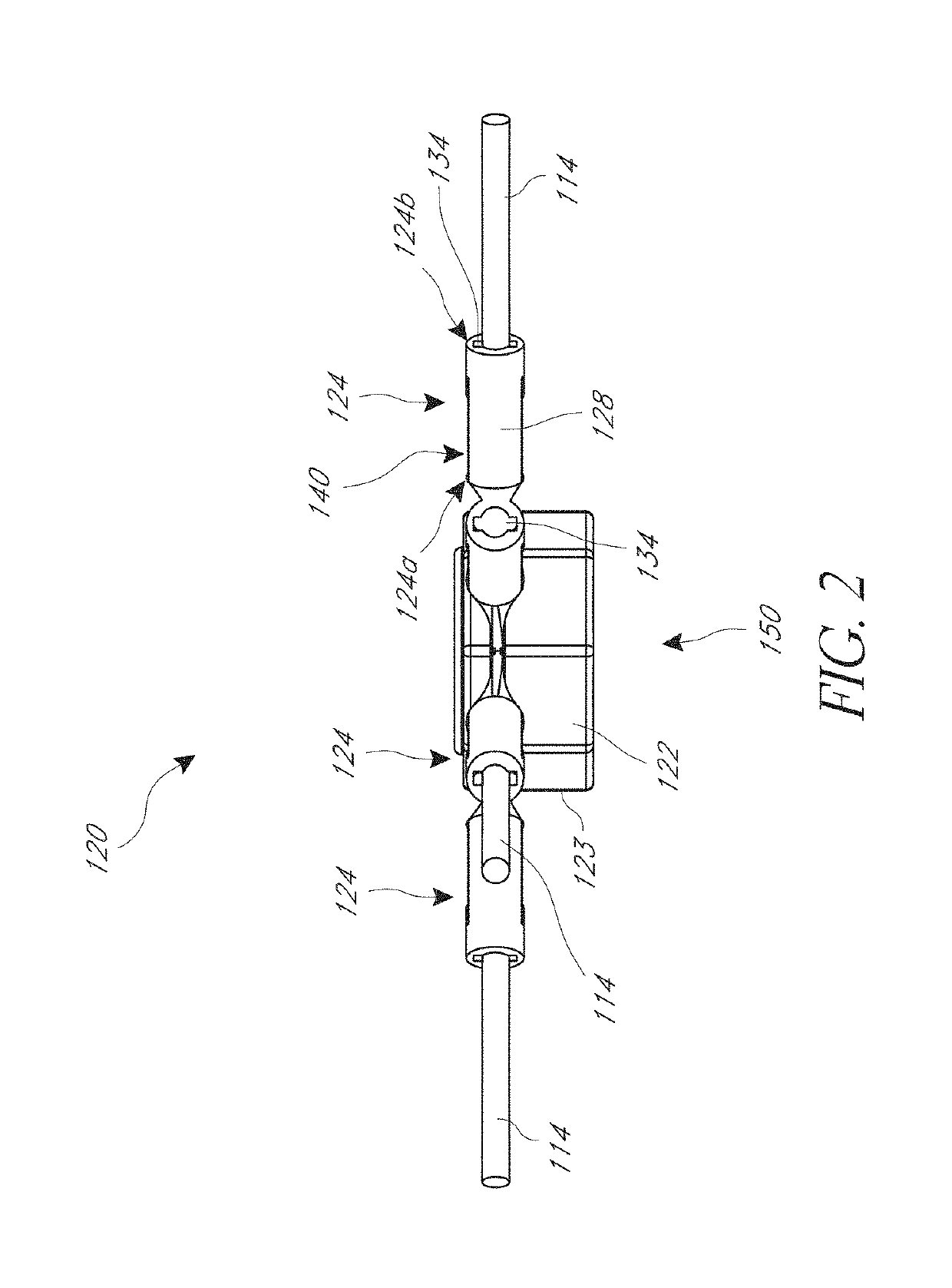

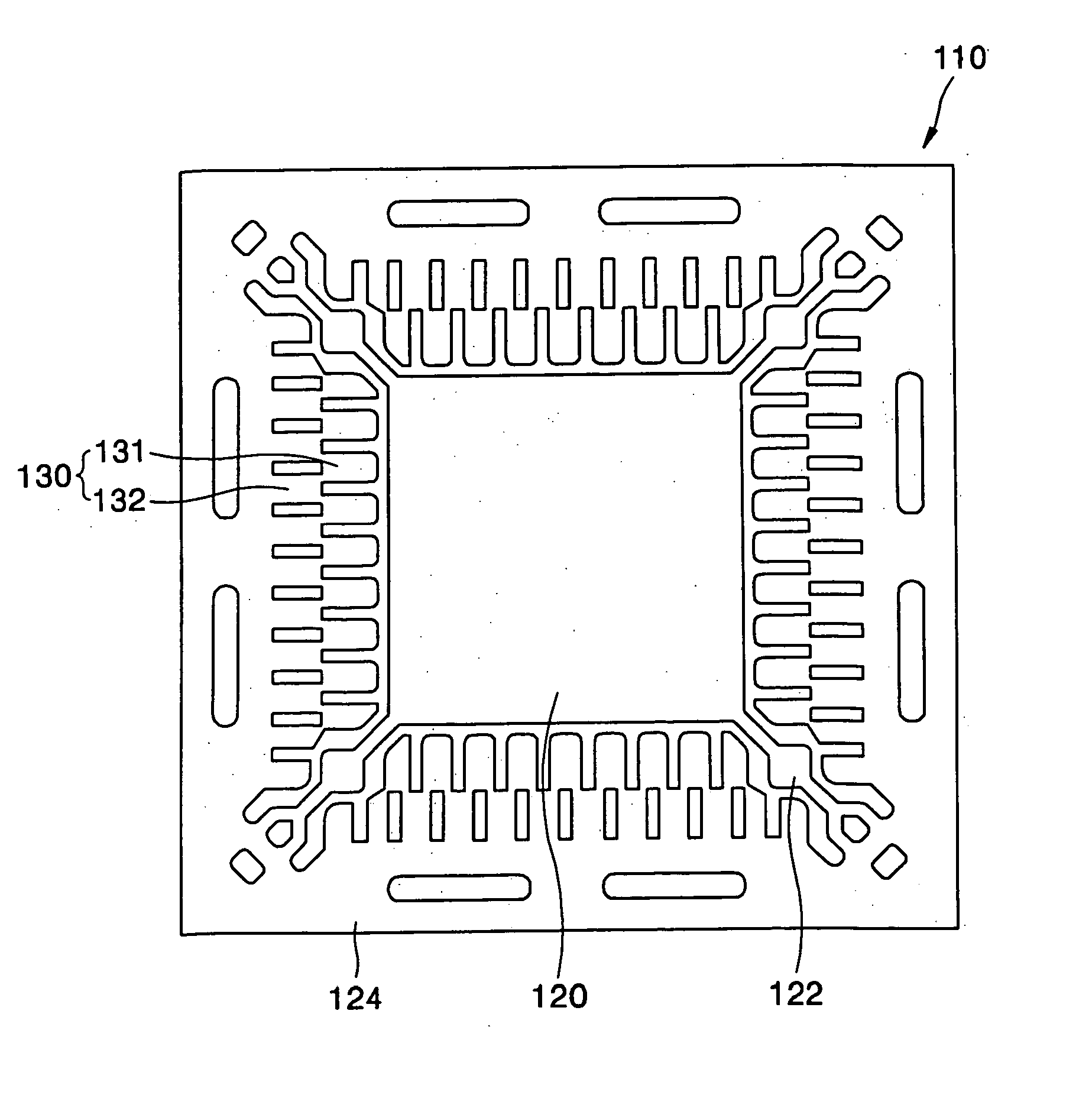

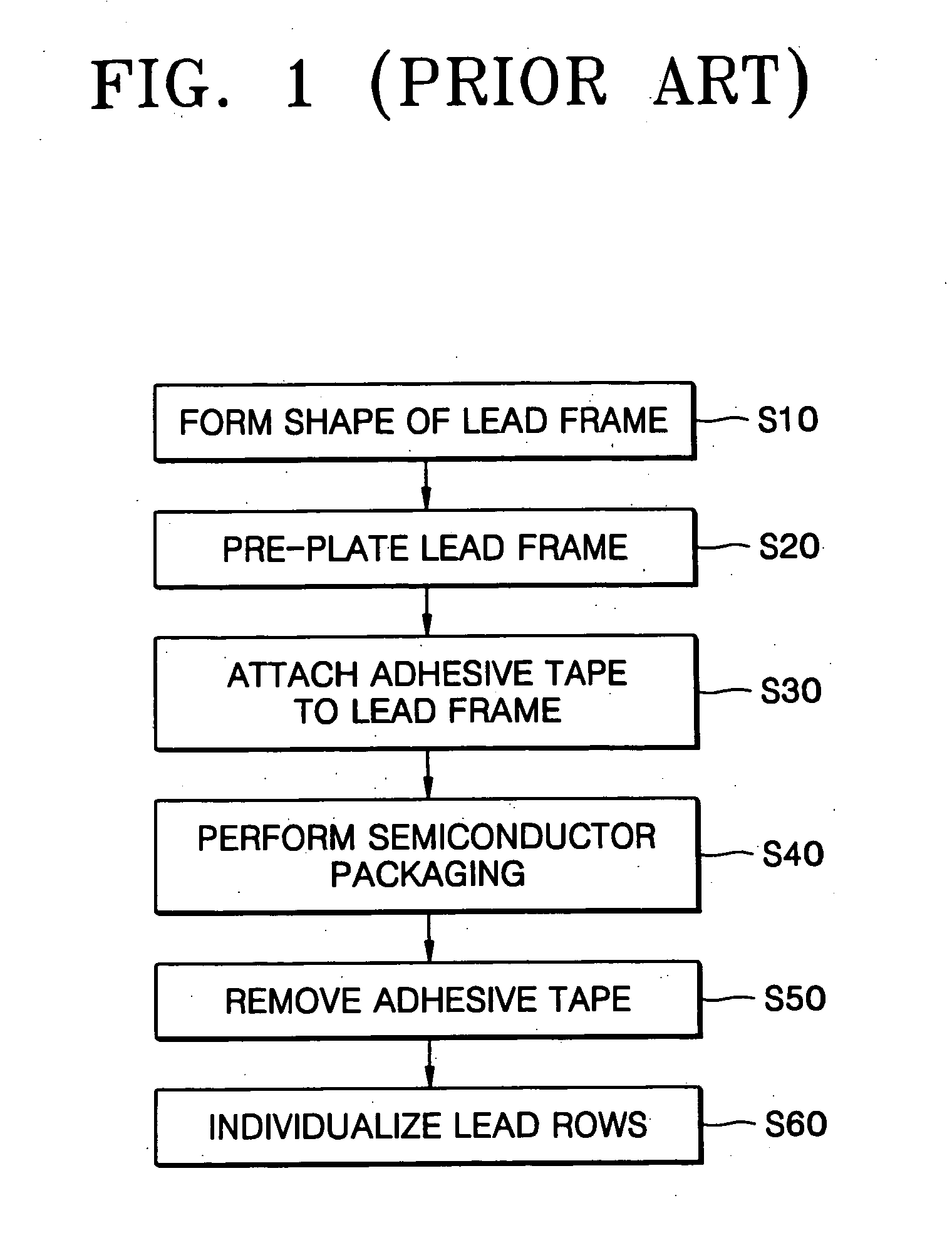

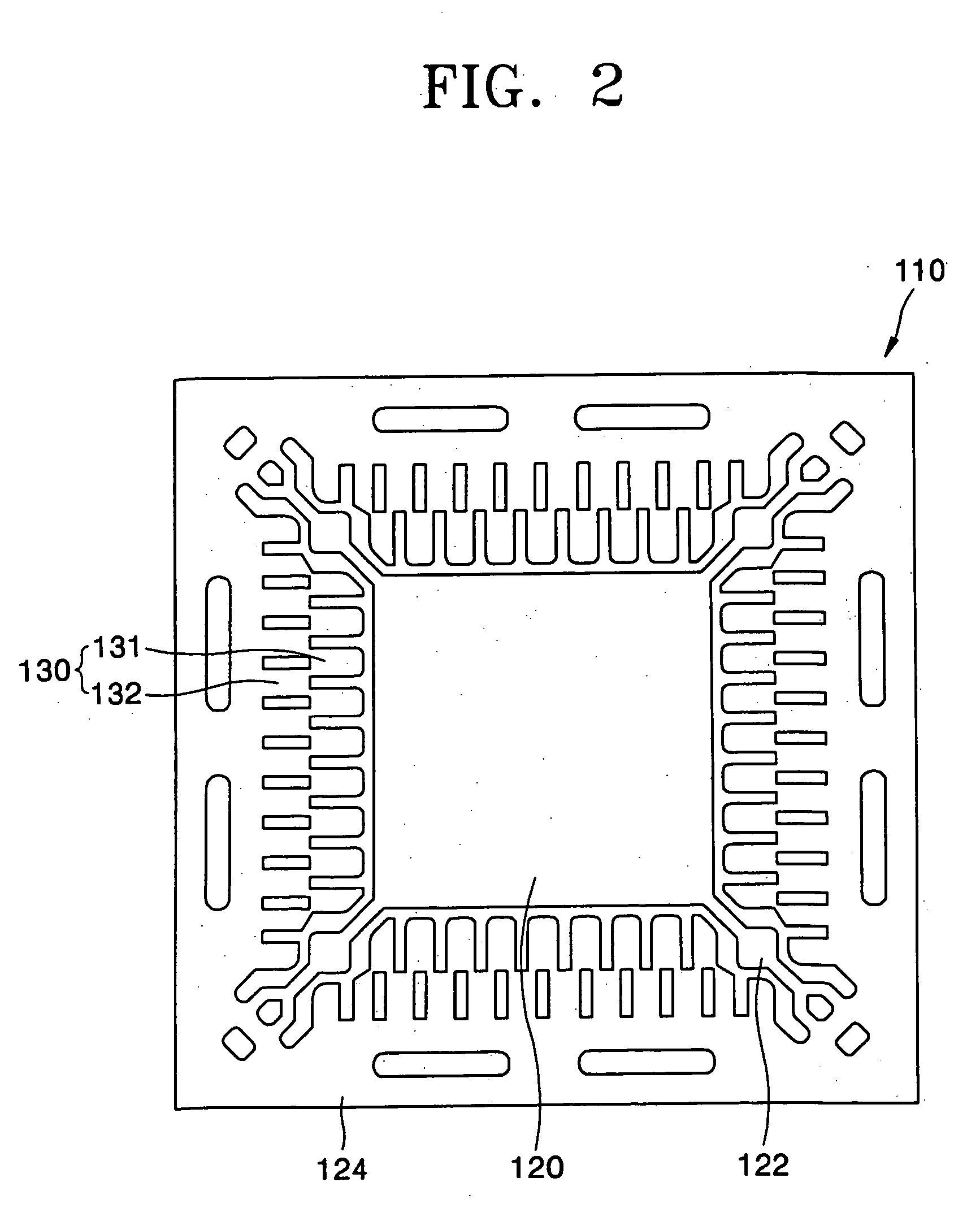

Semiconductor package having multiple row of leads

ActiveUS7173321B2Increase the number ofCumbersome processSemiconductor/solid-state device detailsCasings/cabinets/drawers detailsSemiconductor chipSemiconductor package

Provided is a method of producing a semiconductor package including at least two rows of leads in which the leads of each row separately connecting a semiconductor chip to an external substrate. The method includes: forming a lead frame, the lead frame including a die pad and a plurality of leads arranged about the die pad; attaching an adhesive tape to a surface of the lead frame covering at least substantially the die pad and the plurality of leads; removing portions of the leads and the adhesive tape disposed in a dividing region and thereby separating at least some of the plurality of leads to form multiple rows of leads; and mounting a semiconductor chip on the die pad, electrically connecting the semiconductor chip with the lead frame, and molding the lead frame and the semiconductor chip to provide a semiconductor package. The adhesive tape attached at undesirable locations of the lead frame is preferably removed after provision of the semiconductor package.

Owner:HAESUNG CO LTD

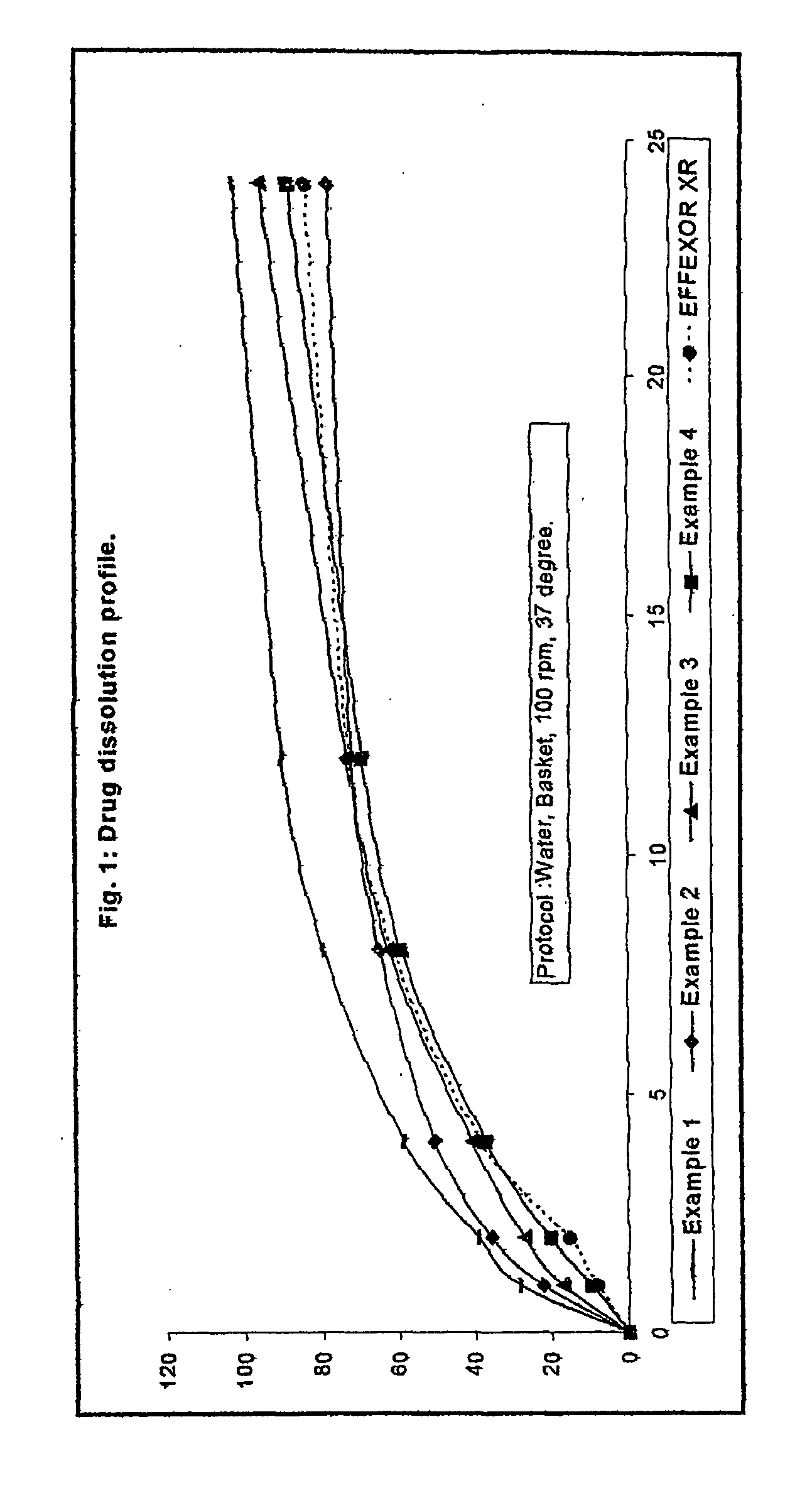

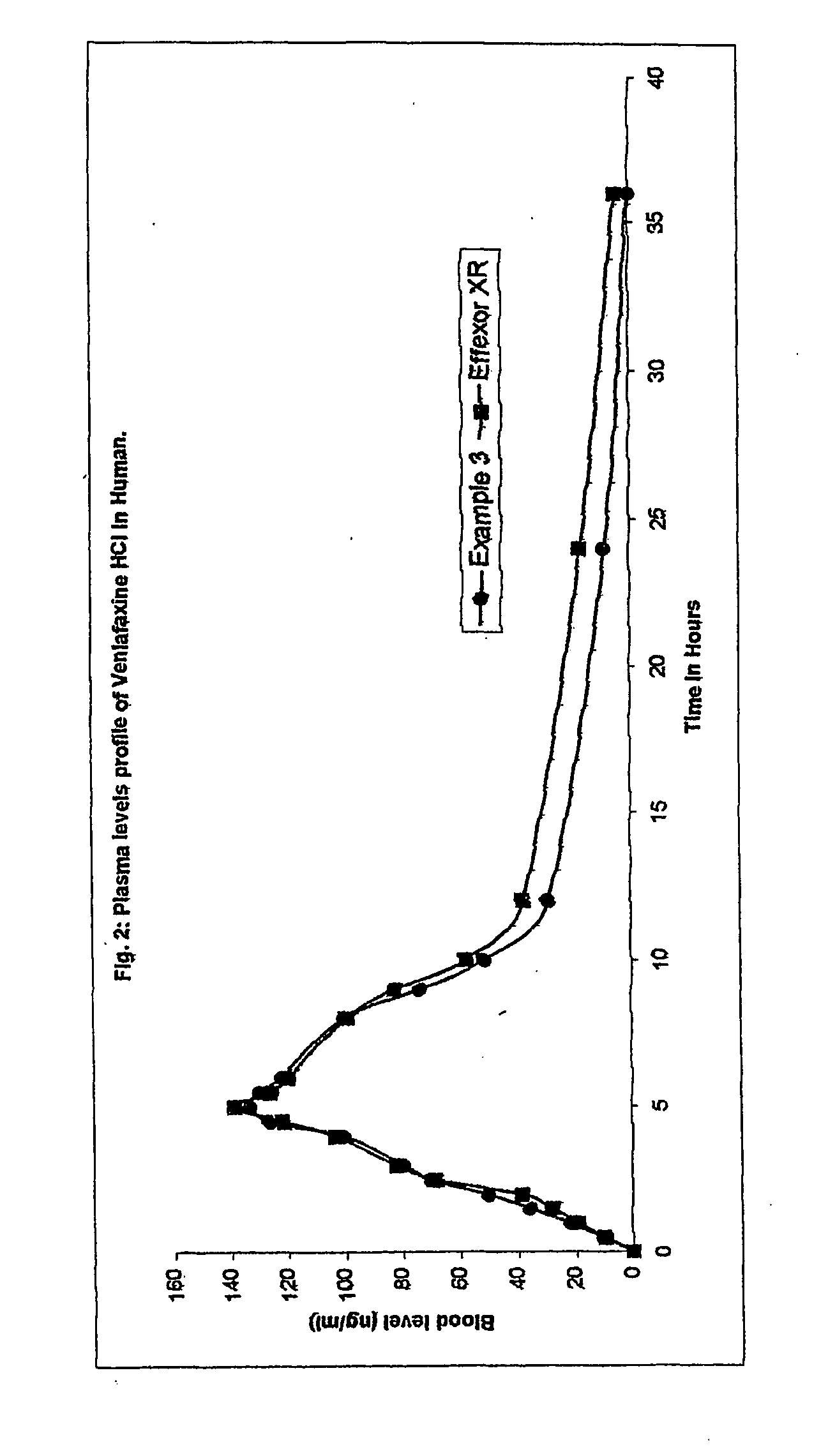

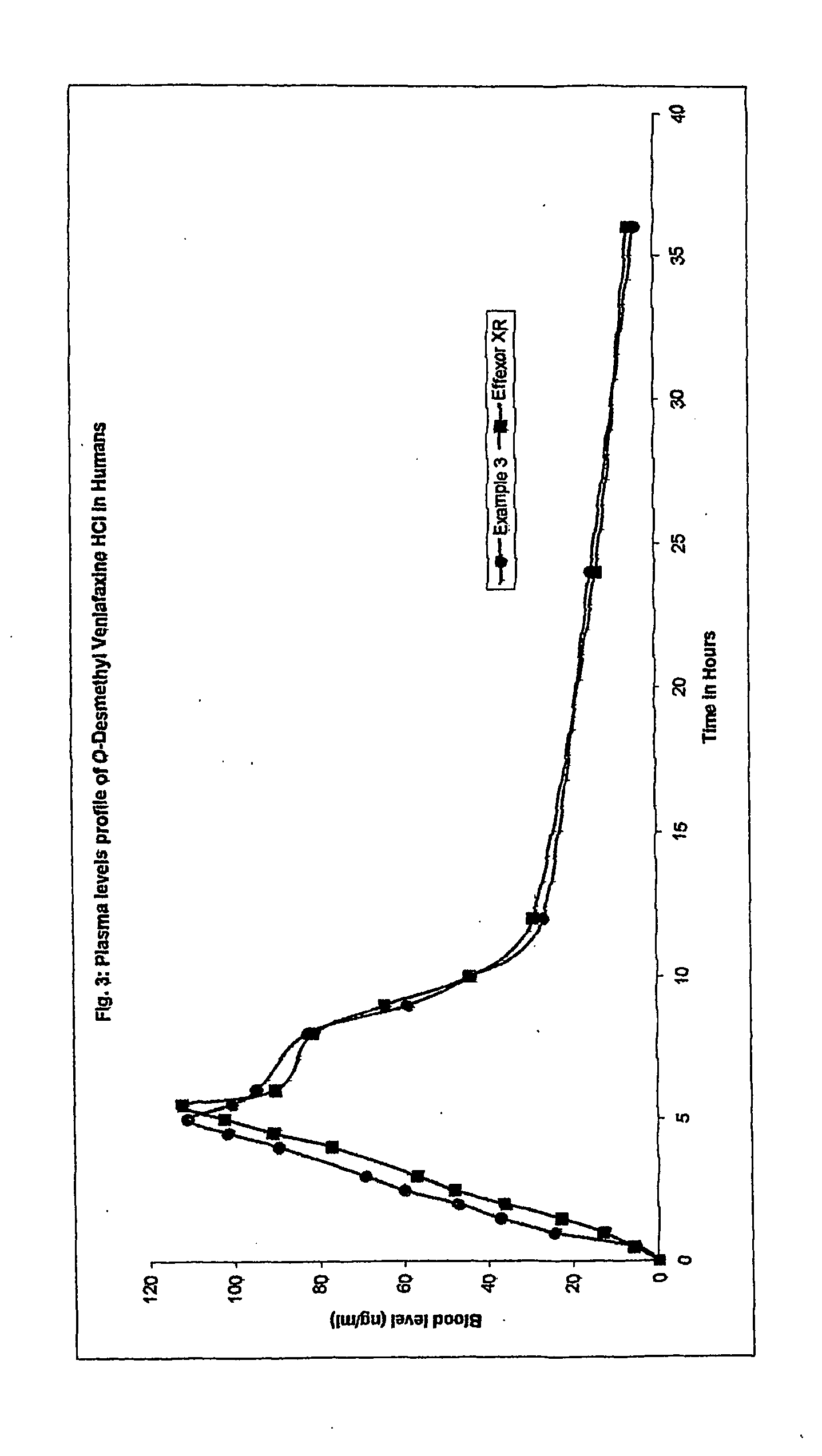

Extended release osmo-microsealed formulation

InactiveUS20070110808A1Good water solubilityEffective controlBiocideOrganic active ingredientsParticulatesHydrophilic polymers

The extended release osmo-microsealed formulation includes three controlled release systems associated in series. First, there is an inner solid particulate phase containing Venlafaxine Hydrochloride (Active), and one or more hydrophobic polymers, one or more diluents required to increase the bulk one or more osmogen (agents which can generate osmotic pressure across the hydrophobic coating) and one or more binder polymers essentially to provide strength / hardness to the particle. Second, there is an outer solid continuous phase including one or more hydrophilic polymers, that is further compressed into a tablet. Third, there is an optional functional coat surrounding the tablet. The process / method for forming the Osmo-microsealed extended release delivery system and the process for using such system for treating human ailment / depression are also provided.

Owner:ALEMBIC LTD

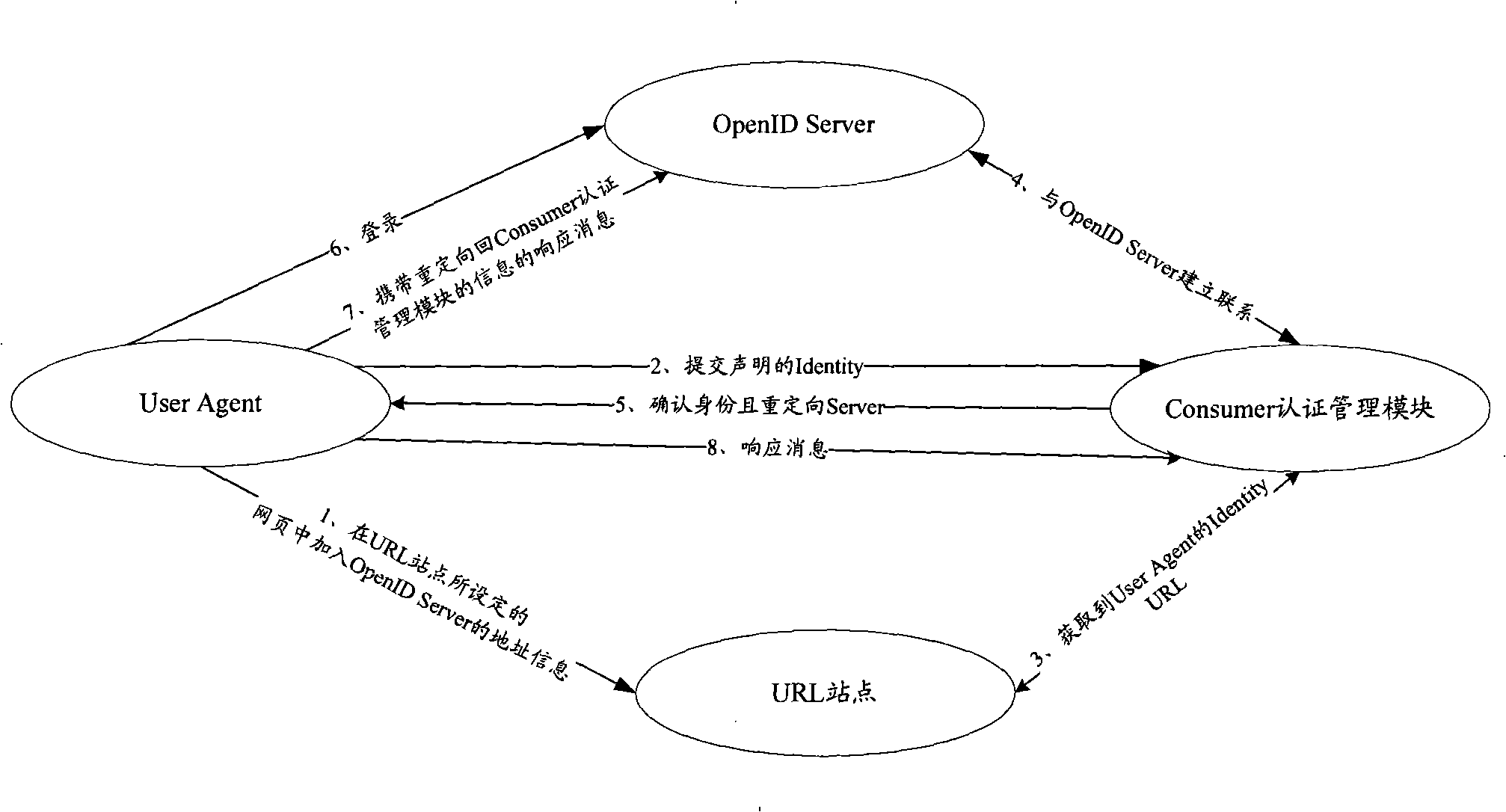

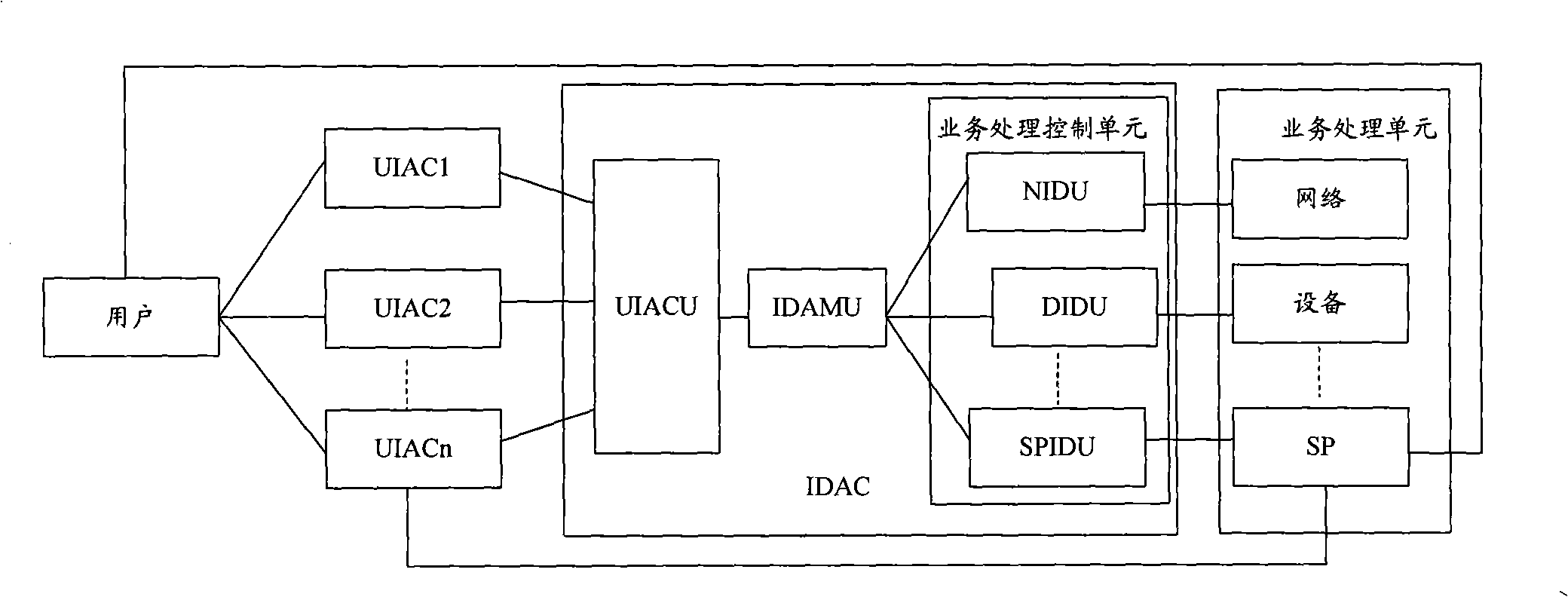

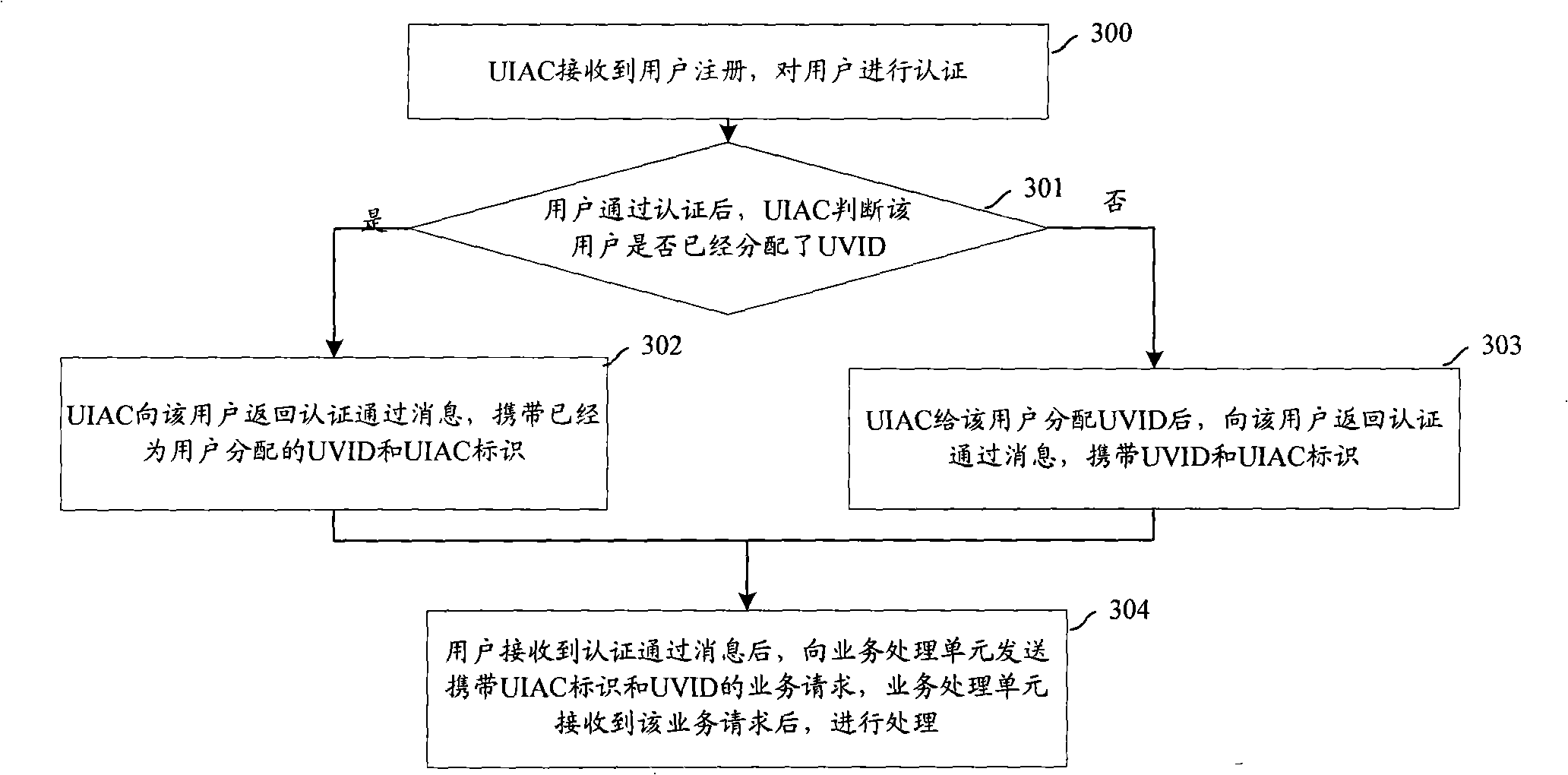

System, device and method for identity security authentication

InactiveCN101291220AImprove securityCumbersome processKey distribution for secure communicationUser identity/authority verificationSecurity authentication

The invention discloses a system, a device and a method for safe identity authentication. The system comprises an identity authentication center, a user identity authentication center and a service processing unit, wherein, the user identity authentication center is used for distributing identity authentication center identification to the identity authentication center and distributing identification to the service processing unit; the identity authentication center is used for distributing user virtual identification uniquely identifying the user to the user register and for sending the user virtual identification and the distributed user identity authentication center identification to the user; and the service processing unit is used for receiving a service request, authenticating the user according to the user virtual identification and the user identity authentication center identification carried by the request and processing the service request. The system, the device and the method can not only improve the security of the user identity authentication but also effectively protect the privacy of the user identity information.

Owner:HUAWEI TECH CO LTD

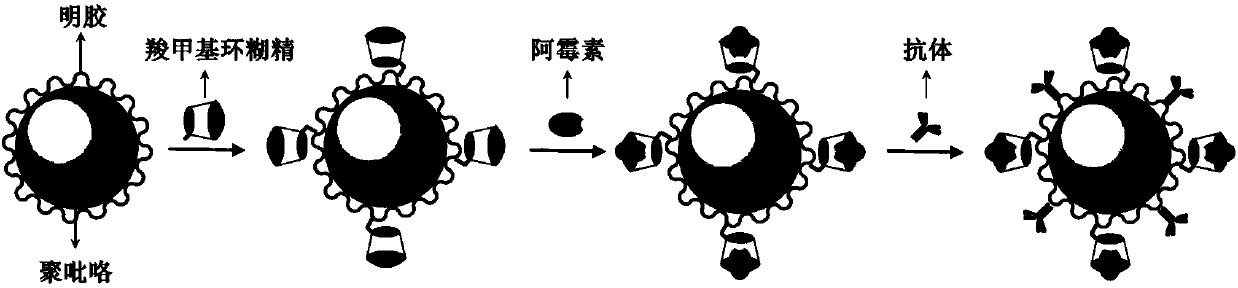

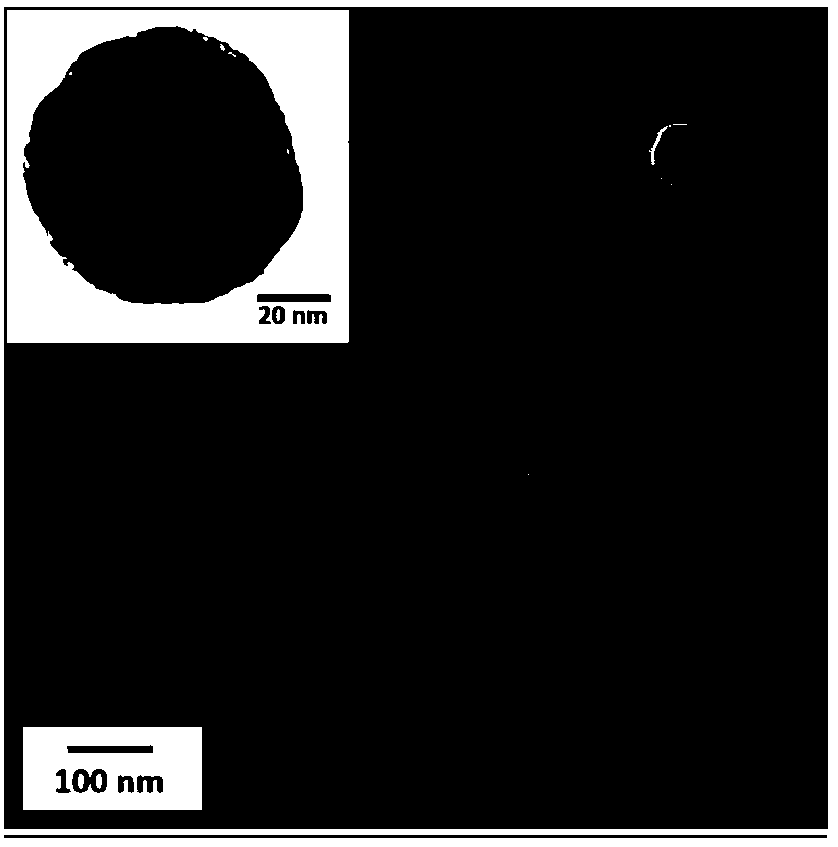

Diagnosis and treatment preparation with multi-stimuli-responsive medicine controlled release function and preparation method and application thereof

ActiveCN107596366AHigh biosecuritySolve the complex surface modification processEnergy modified materialsEchographic/ultrasound-imaging preparationsSide effectMedical physics

The invention discloses a diagnosis and treatment preparation with a multi-stimuli-responsive medicine controlled release function and a preparation method and application thereof. According to the prepared preparation, polypyrrole nano particles are used as a core and externally modified by a cyclodextrin-chemotherapeutics compound and a targeted group, and the preparation has the effects of multi-stimuli-responsive medicine controlled release, photoacoustic imaging and chemotherapeutic and photo-thermal combined treatment. According to the preparation, three medicine controlled release mechanisms including pH values, gelatinase and photo-thermal response are combined, and the selectivity of chemotherapeutics to tumors is improved; imaging and treatment are fused, in-vivo distribution ofthe preparation can be monitored in real time, and the laser radiation position, power and time during photo-thermal treatment are guided; and chemotherapeutics and photo-thermal treatment are combined, so that the tumor recurrence rate is effectively lowered. By means of the composite preparation, the diagnosis and treatment efficiency is effectively improved, the medical effect is improved, thetoxic and side effects are lowered, and the diagnosis and treatment preparation has good clinic application prospects.

Owner:INSITUTE OF BIOPHYSICS CHINESE ACADEMY OF SCIENCES +1

Systems and methods to facilitate interactions in an interactive space

ActiveUS10168768B1Cumbersome processReduce noiseInput/output for user-computer interactionDetails for portable computersHuman–computer interaction

Owner:META +1

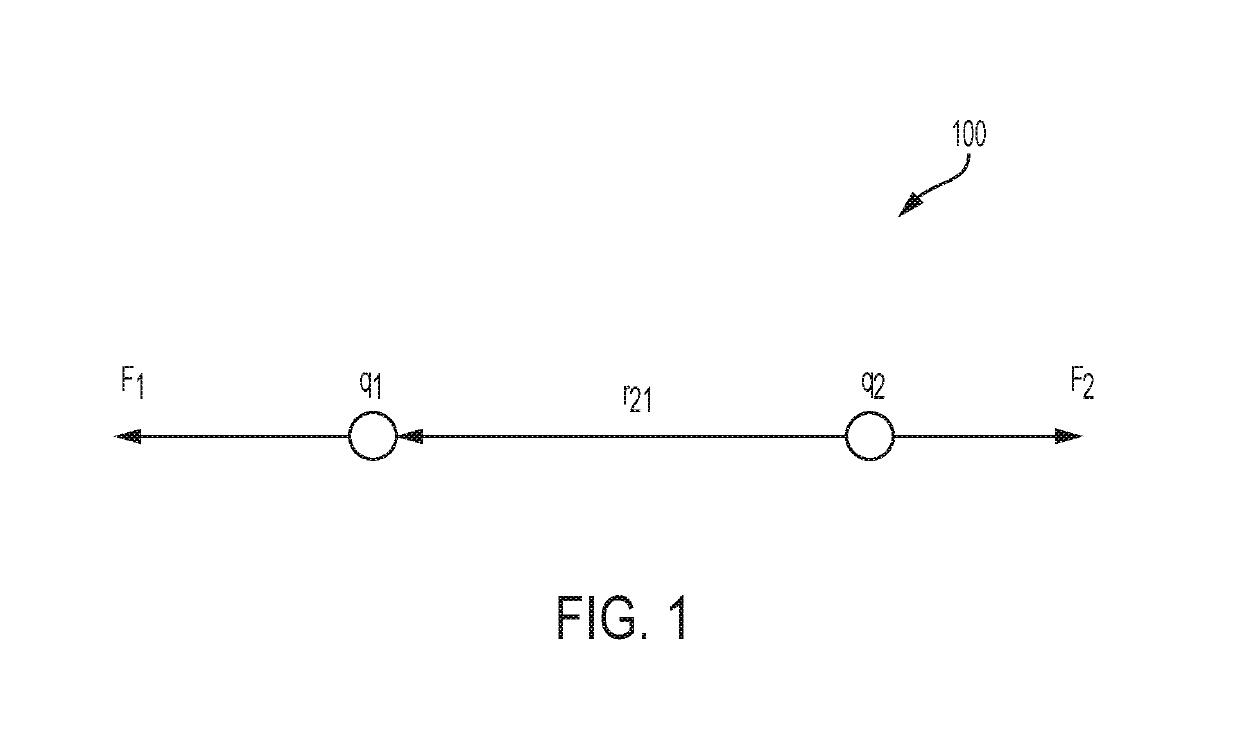

Systems and methods for reducing processing load when simulating user interaction with virtual objects in an augmented reality space and/or evaluating user interaction with virtual objects in an augmented reality space

ActiveUS10489931B1Cumbersome processReduce noiseInput/output for user-computer interactionImage enhancementVirtual worldAugment reality

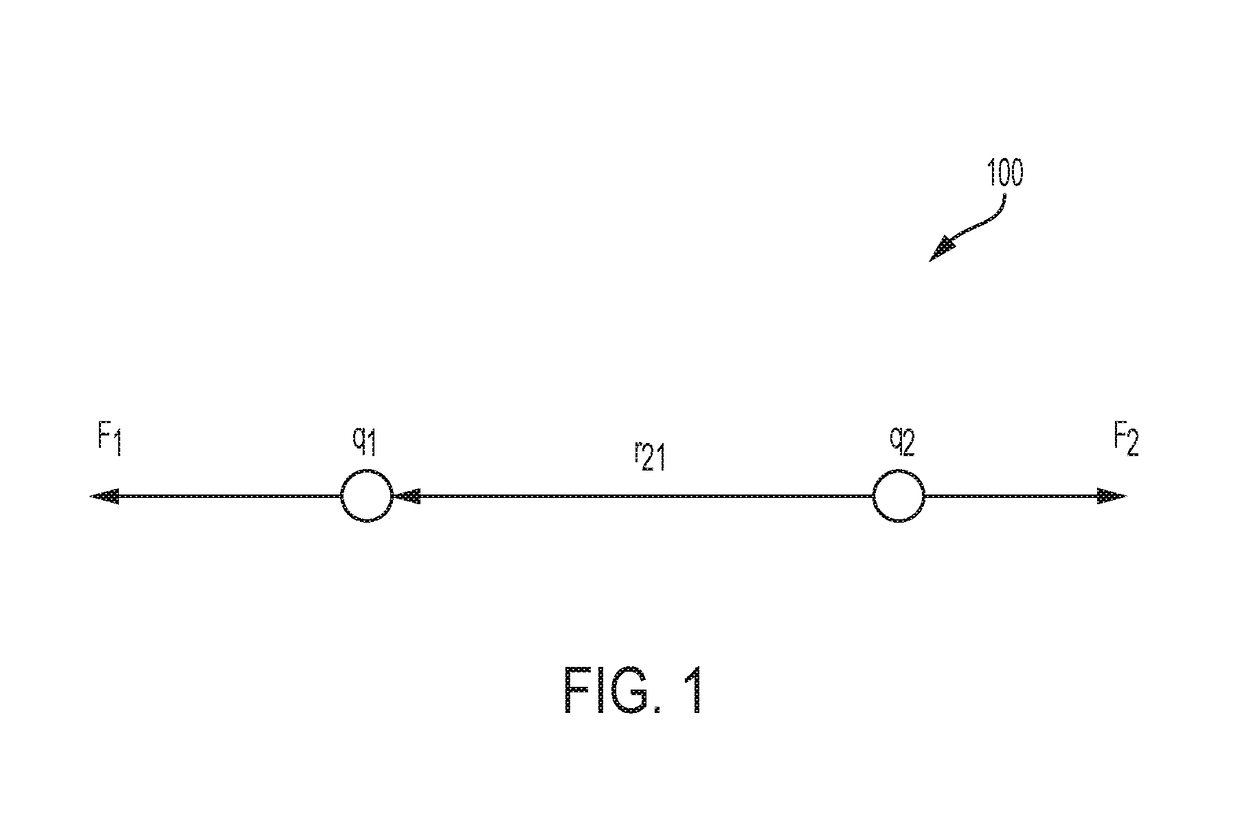

Systems and methods for reducing processing load when simulating user interaction with virtual objects in an interactive space and / or evaluating user interaction with virtual objects in an interactive space are described herein. Interactions may include interactions between one or more real-world objects and one or more virtual objects. A real world object may be detected and / or modeled in a virtual world as a collection of point charges.

Owner:META +1

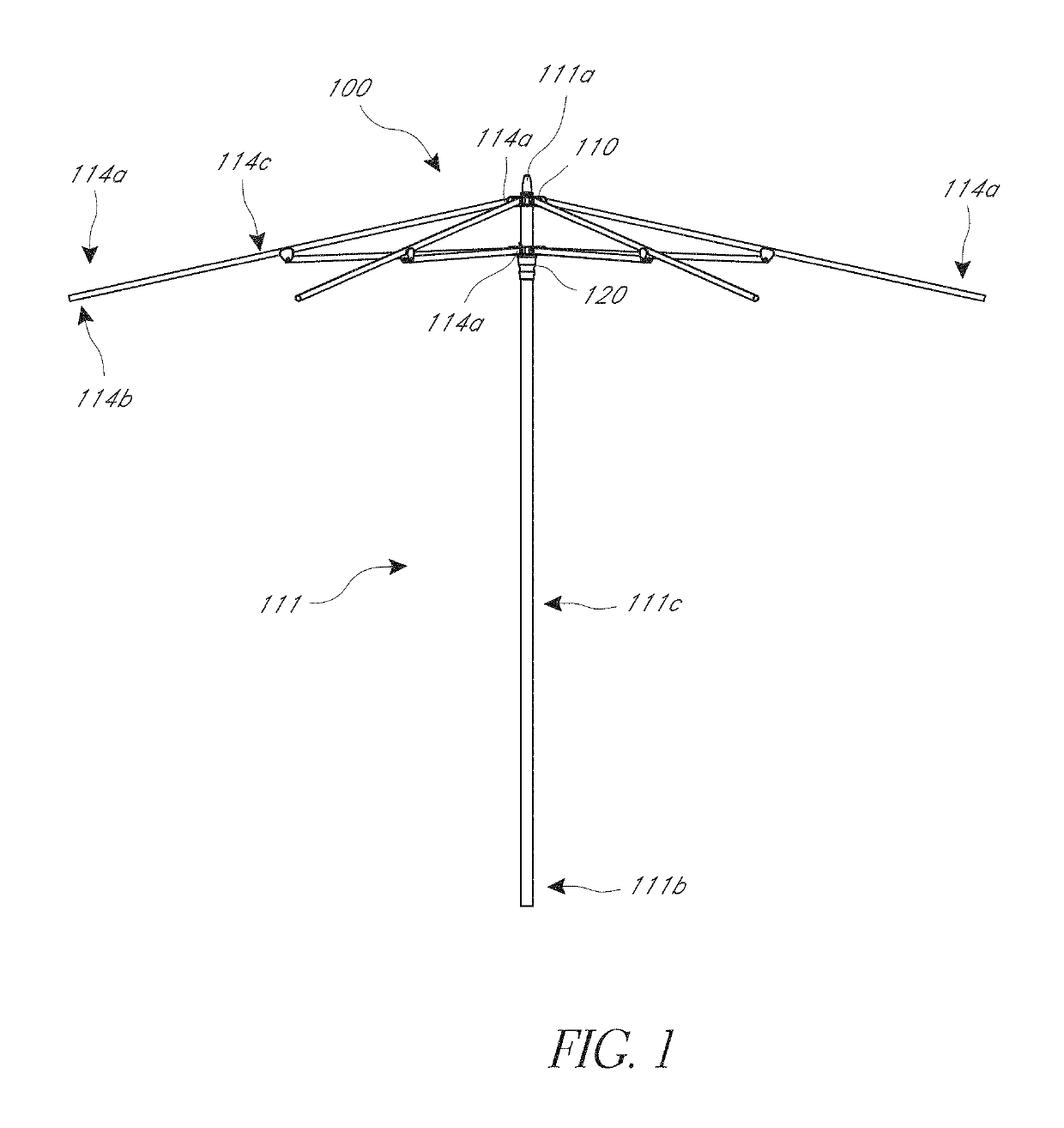

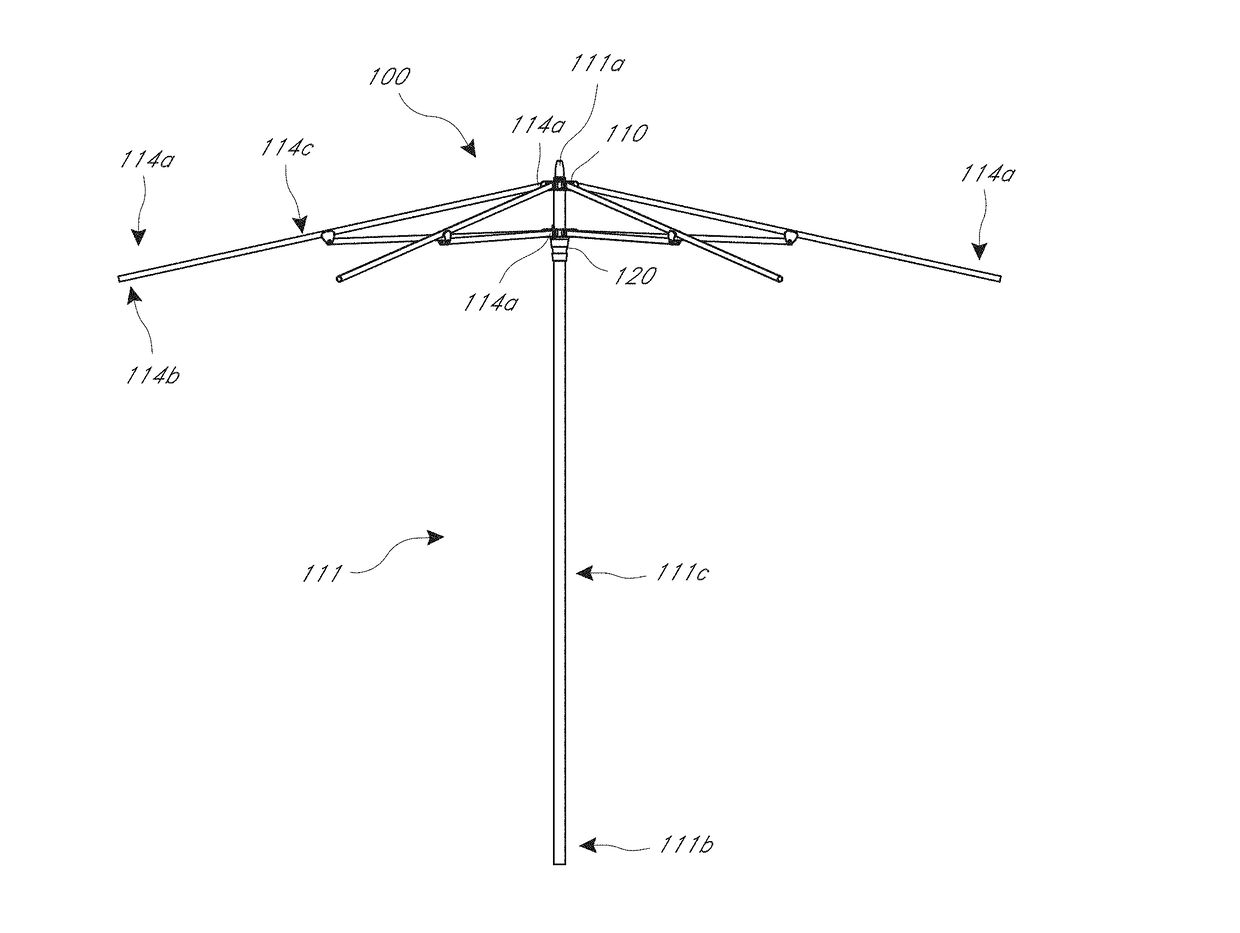

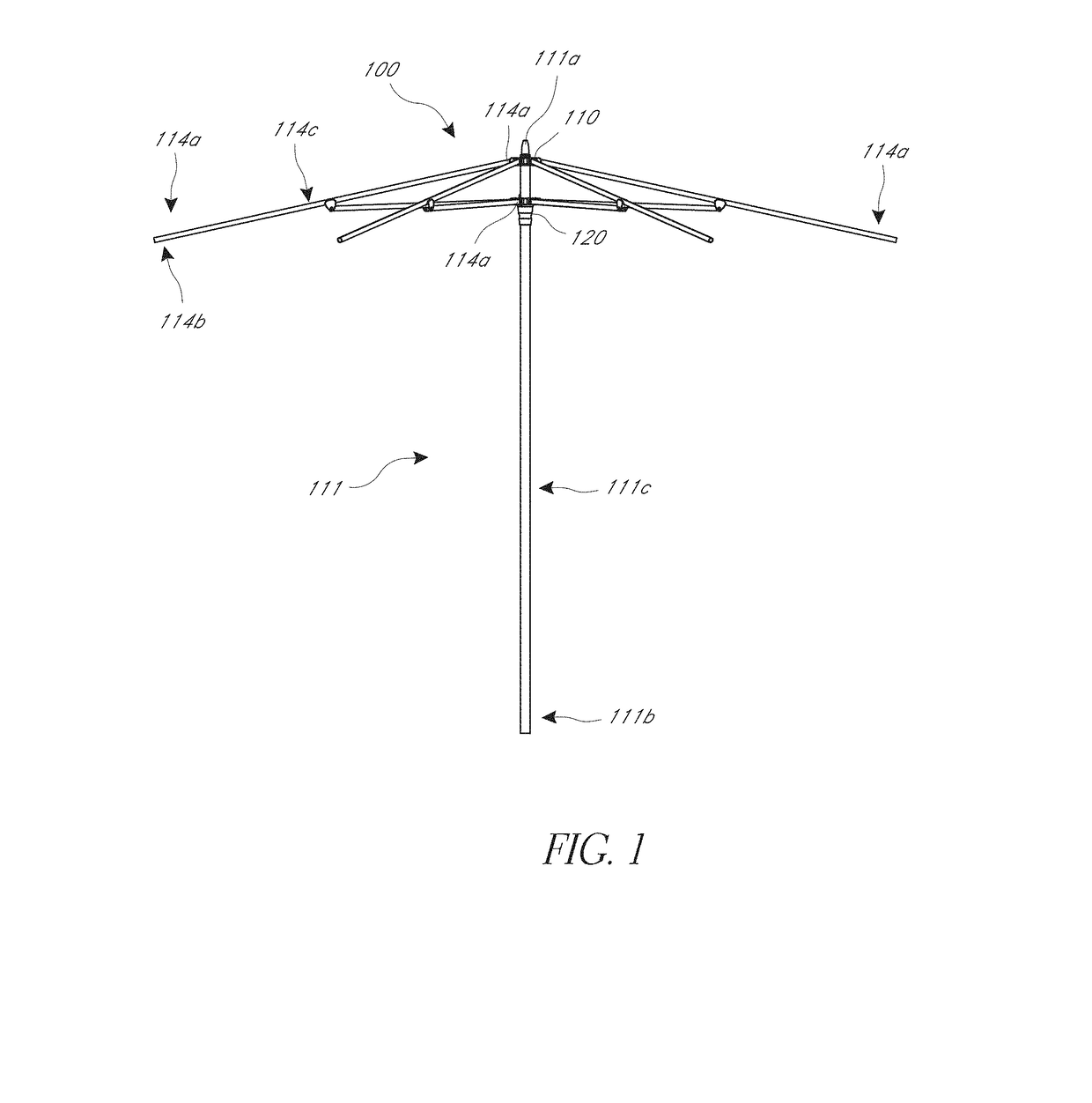

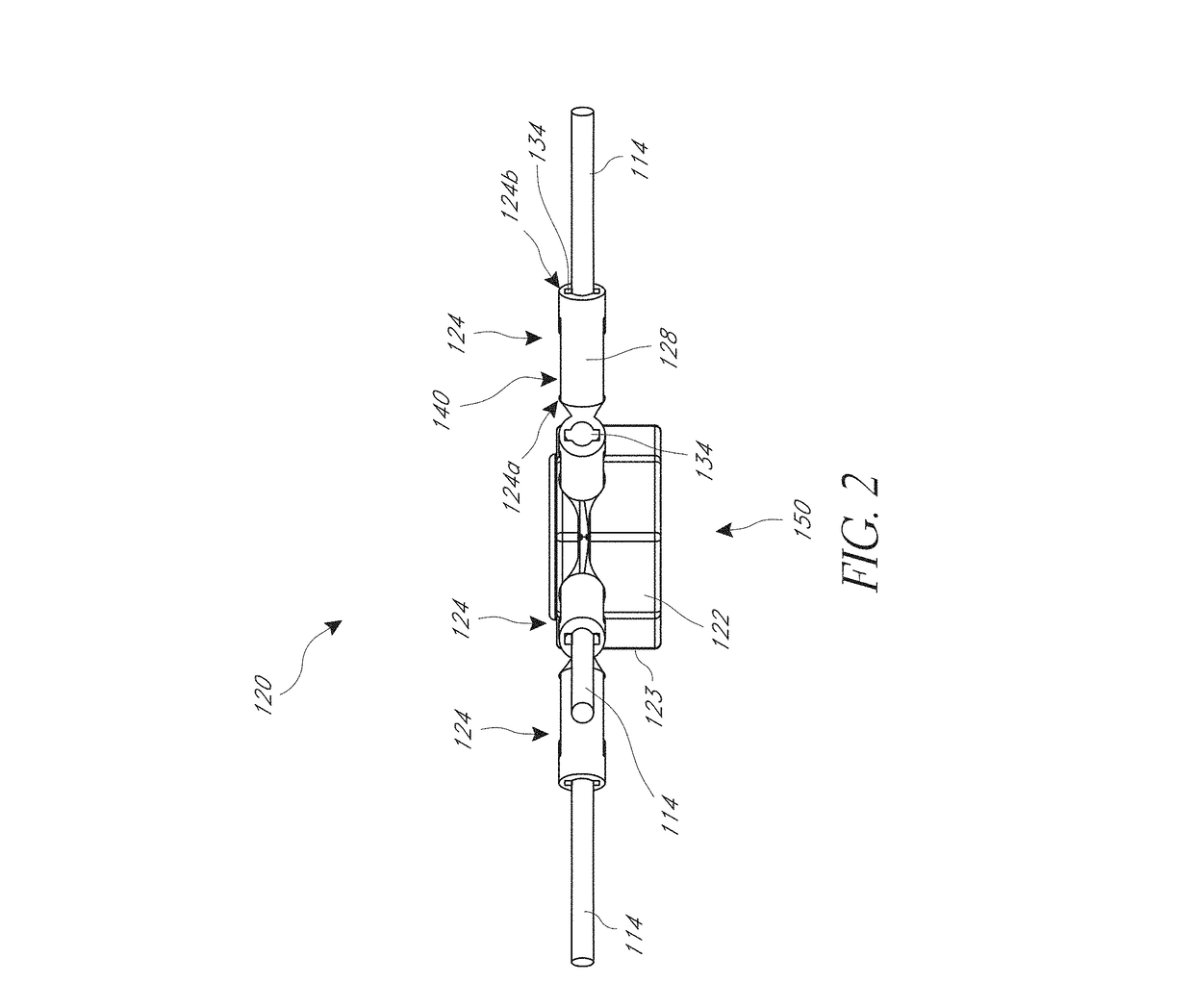

Umbrella rib connector assemblies and methods

Owner:MA ZHUN AN

Method of manufacturing semiconductor package having multiple rows of leads

ActiveUS20050233500A1Increase the number ofCumbersome processSemiconductor/solid-state device detailsCasings/cabinets/drawers detailsSemiconductor chipSemiconductor package

Provided is a method of producing a semiconductor package including at least two rows of leads in which the leads of each row separately connecting a semiconductor chip to an external substrate. The method includes: forming a lead frame, the lead frame including a die pad and a plurality of leads arranged about the die pad; attaching an adhesive tape to a surface of the lead frame covering at least substantially the die pad and the plurality of leads; removing portions of the leads and the adhesive tape disposed in a dividing region and thereby separating at least some of the plurality of leads to form multiple rows of leads; and mounting a semiconductor chip on the die pad, electrically connecting the semiconductor chip with the lead frame, and molding the lead frame and the semiconductor chip to provide a semiconductor package. The adhesive tape attached at undesirable locations of the lead frame is preferably removed after provision of the semiconductor package.

Owner:HAESUNG CO LTD

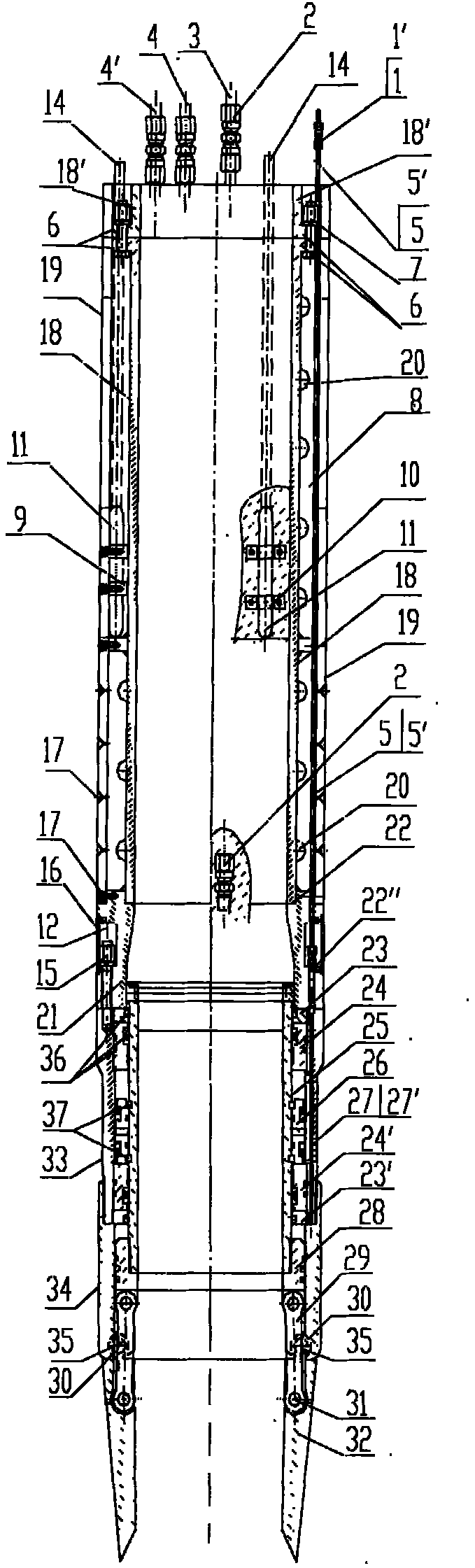

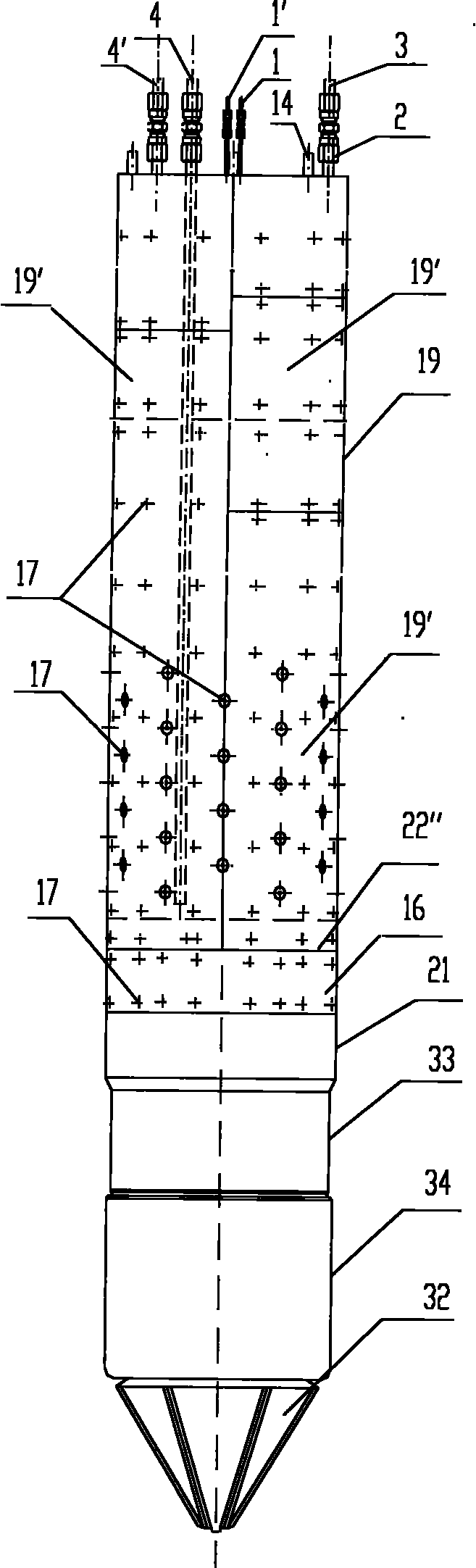

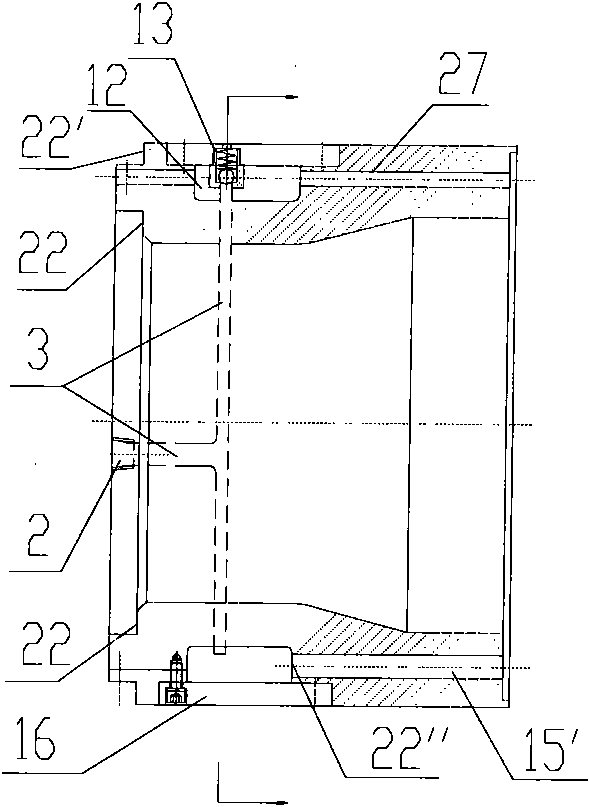

Multi-disk pouring pile one-step molding device and construction method thereof

The invention relates to a pressure grouting and vibrator built-in multi-disk pouring pile one-step molding device and a construction method thereof, belonging to the technical fields of piling machinery and construction of building industry. In the device, by adopting pressure grouting structure and built-in vibrator structure characteristics, a plurality of disk pouring piles are molded in one step by high-pressure guniting and vibrating pile pulling for synchronously constructing concrete vibration tamping extruded expansion through eight procedures of forming pores, expanding the disks several times, carrying out automatic pressure guniting on the peripheral side of a pile body in the pressing process or changing soft soil into higher-strength cement soil character by cement nano slurry, placing a reinforcement cage, pouring cement, carrying out automatic pressure guniting on the peripheral side of the pile body again in the lifting process, vibrating and pulling the pile by the built-in vibrator for synchronously constructing concrete controllable vibration tamping and molding the pile. The invention has simple main body structure, safe and reliable construction operation, simple and convenient construction procedure, high frictional resistance of the soft soil, high bearing capacity of the pile and environmental-friendly construction site.

Owner:QINGDAO JINGLI ENG

Attack protection for a packet-based network

ActiveUS8601564B2Cumbersome processReduce processing loadMemory loss protectionError detection/correctionNetwork packet

The invention relates to a protection unit for protecting a packet-based network from attacks, comprising: a signature analyzer for analyzing a packet stream received in a security border node of the packet-based network and for detecting attacks by comparing signatures of the packet stream with a set of signatures of previously identified attacks, an anomaly detector for detecting anomalies in the packet stream, and a signature interference unit for updating the set of signatures when anomalies in the packet stream are detected, the updated set of signatures being subsequently used for performing the signature analysis. A distribution unit distributes at least one signature of the updated set of signatures to at least one further security border node of the packet-based network. The invention also relates to a security border node comprising such a protection unit, a network comprising at least two such protection units, and a corresponding protection method.

Owner:ALCATEL LUCENT SAS

Surface paint spraying technological process for larger-area metal workpiece

InactiveCN104549934AStrict process requirementsCumbersome processPretreated surfacesCoatingsSpray nozzleScratching

The invention relates to a surface paint spraying technological process for a larger-area metal element. According to the surface paint spraying technological process, oil stain on the surface of the metal workpiece in the production process is removed, and cleaning is carried out; rust scale on the steel surface is removed by acid, and cleaning is carried out; the steel surface is phosphatized by a zinc-system phosphate solution, and cleaning is carried out; workpiece paint spraying is carried out after the drying phosphorization and the cleaning; before the paint spraying, variety selection, performance selection, uniform mixing, viscosity selection, purification filtering and color regulation of paint are prepared; during paint spraying, the proper paint and the proper viscosity of the workpiece to be sprayed are selected according to the workpiece to be sprayed, and are determined according to the paint type, the air pressure, the spray nozzle size and the requiring quantity of the sprayed area; polymerized paint is dried, the ordinary drying temperature is 130 to 140 DEG C, the drying time is 30 to 35 minutes, and the polymerized paint is dried; the drying degree of a paint film is checked, and the thickness, the adhesive force, the color, the luster and the surface state of the paint film are checked through visual inspection or cutter blade scratching. The surface paint spraying technological process for the larger-area metal element has the advantages that sprayed paint on the workpiece surface is enabled not generate leak points and peeling, the labor and the materials are saved, the cost is reduced, and the quality is excellent.

Owner:SHANDONG GOLDKING ELECTRICAL APPLIANCES

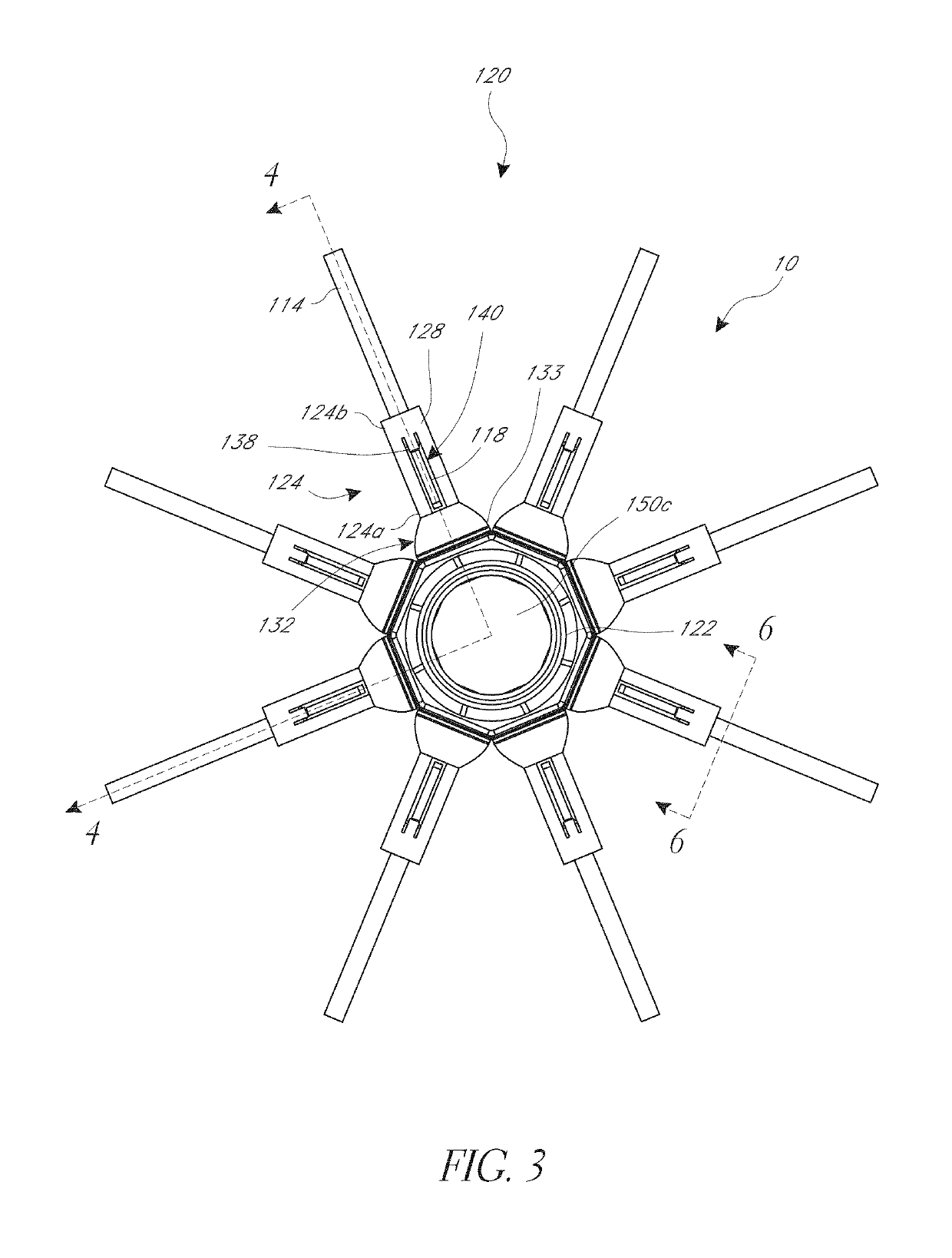

Umbrella rib connector assemblies and methods

ActiveUS20180110303A1Reduce replacement labor and costProtect structural integrityWalking sticksEngineering

In one aspect of the present disclosure, an umbrella hub assembly comprises an a cylindrical portion and a socket coupled to the cylindrical portion. The socket can have a fixed end, a free end, and a cylindrical wall defining a concave space extending from the free end toward the fixed end. The socket can have an access aperture disposed through the cylindrical wall. The assembly can further include an umbrella rib comprising a first end, a second end, and an elongate body extending along a longitudinal axis. The first end can be configured to be received in the concave space through the free end such that the socket engages the umbrella rib and such that the first end is accessible through the access aperture.

Owner:MA ZHUN AN

Method for preparing super-hydrophobic surface on silicon wafer based on laser interference nanometer lithography

ActiveCN103663358AHigh surface energyImprove hydrophilic abilityDecorative surface effectsPhotomechanical exposure apparatusLight intensityBeam splitting

The invention discloses a method for preparing a super-hydrophobic surface on a silicon wafer based on laser interference nanometer lithography. The method comprises the following steps: (1) simulating a four-beam interference pattern by using Matlab (Matrix Laboratory), setting parameters to simulate an ideal lattice model; building a laser interference optical system according to simulation parameters; emitting a beam of laser through a laser, splitting the beam of laser into four beams of laser through a beam splitting system, in which incidence angles Theta1, Theta2, Theta3 and Theta4 are equal to 15 degrees; phase angles which are polarization angles Psi1, Psi2, Psi3 and Psi4 are equal to 90 degrees; the light intensity energy density ratio of four beams of laser is 1:1:1:1; and etching a lattice structure on a silicon wafer through four beams of laser; (2) removing dust pollutants on the surface of the etched silicon wafer by using ultrasonic vibration; (3) processing the etched silicon wafer by using HF and removing SiO2 to obtain a micro-nano surface structure with a contact angle up to 150 degrees.

Owner:CHANGCHUN UNIV OF SCI & TECH

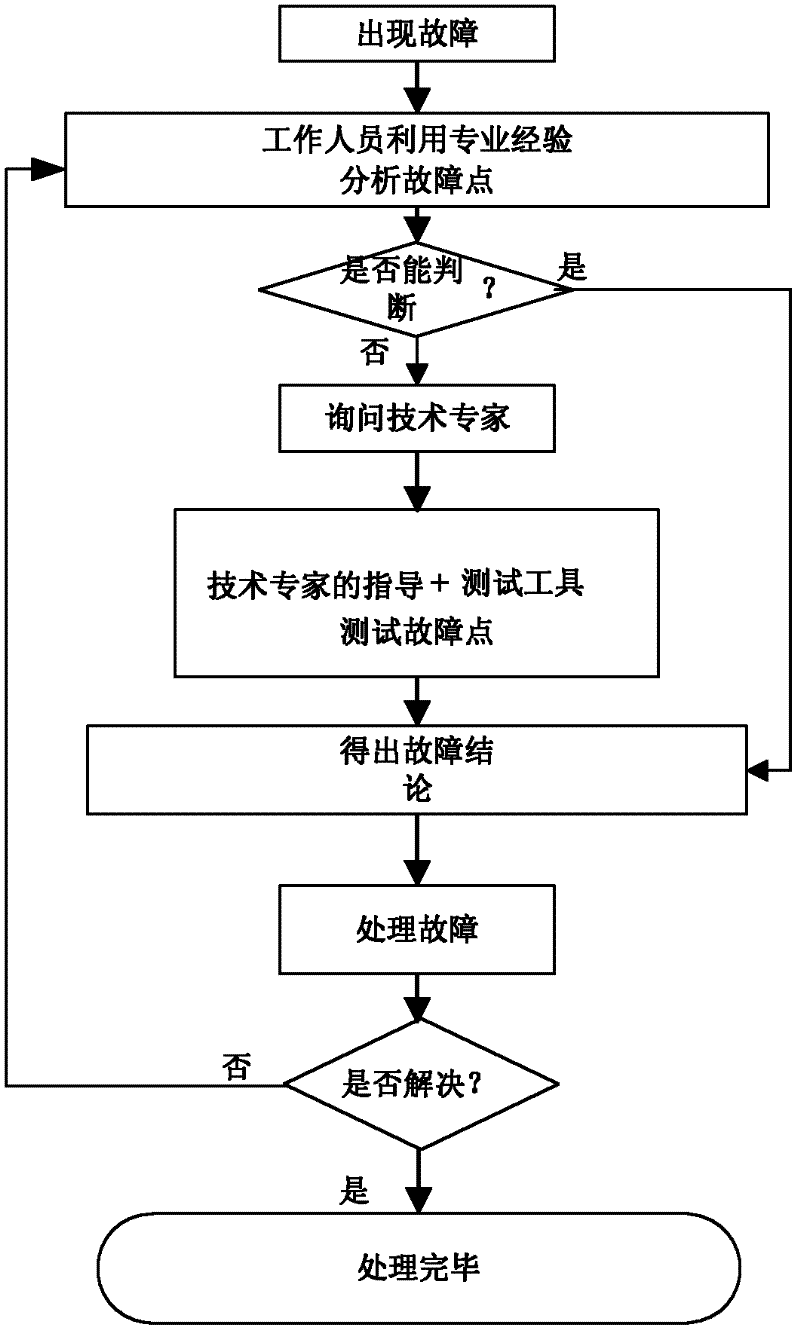

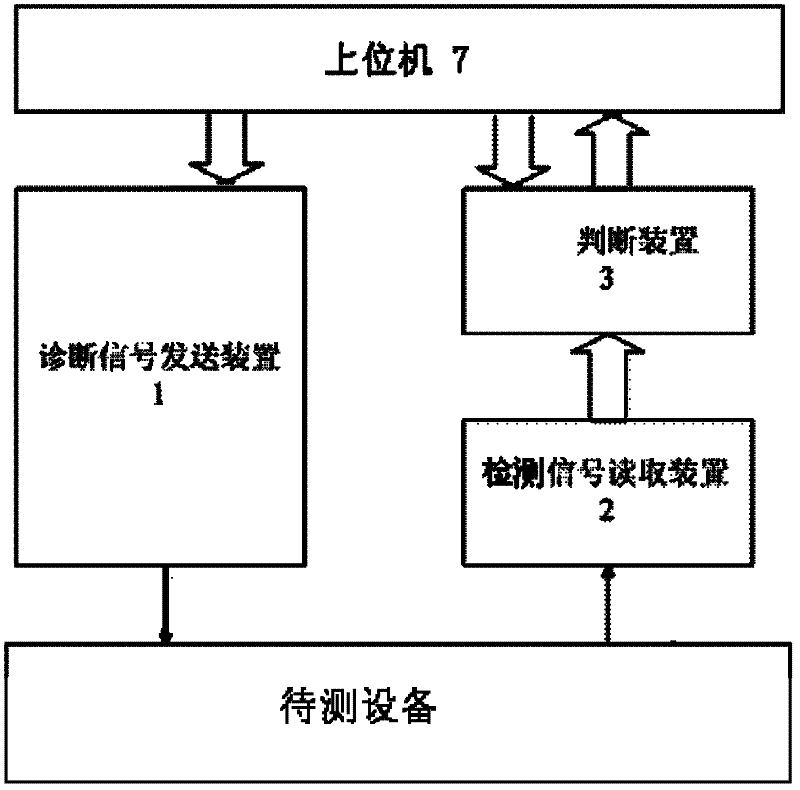

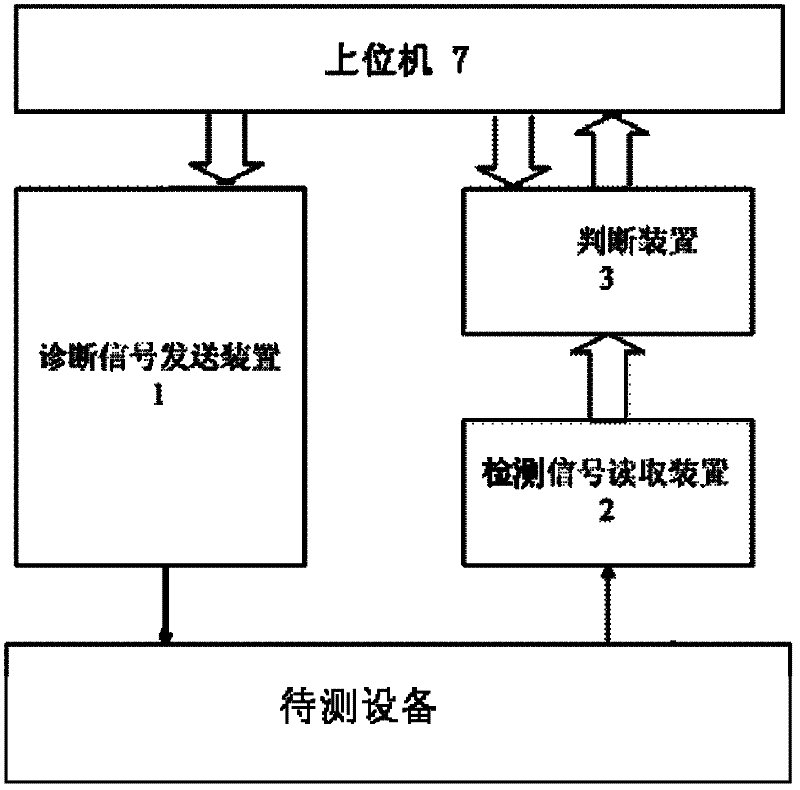

Method, system and engineering machinery for electrical fault diagnosis

InactiveCN102508065APrecise positioningAccurate analysisElectrical testingElectricityElectrical Failure

The invention discloses a method, a system and engineering machinery for electrical fault diagnosis. The method for electrical fault diagnosis includes the steps of sending diagnosis signals to a device or a circuit when the fact that the device or the circuit of to-be-detected equipment is connected with a power supply is detected, reading detection signals from the device or the circuit, and then judging whether a fault exists in the device or the circuit based on the detection signals, or includes the steps of sending the diagnosis signals to the device or the circuit based on initiative diagnosis instructions when the initiative diagnosis instructions are received, reading the detection signals from the device or the circuit, and then judging whether a fault exists in the device or the circuit based on the detection signals. By means of the technical scheme, at least two diagnosis modes of electrifying fault diagnosis and initiative fault diagnosis can be provided, and therefore, accurate location of electrical faults can be achieved, work amount of workers is greatly reduced, diagnosis speed and accuracy are improved, and reliable guarantee is provided for safe operation of the equipment.

Owner:ZOOMLION HEAVY IND CO LTD

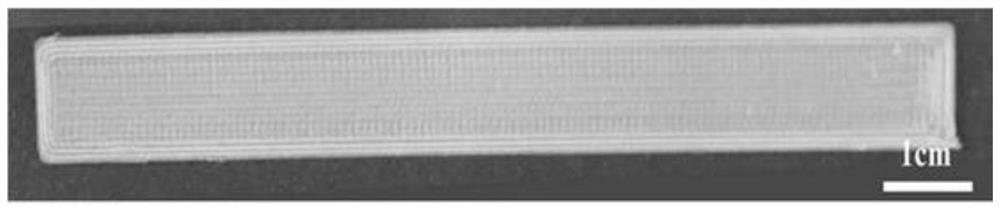

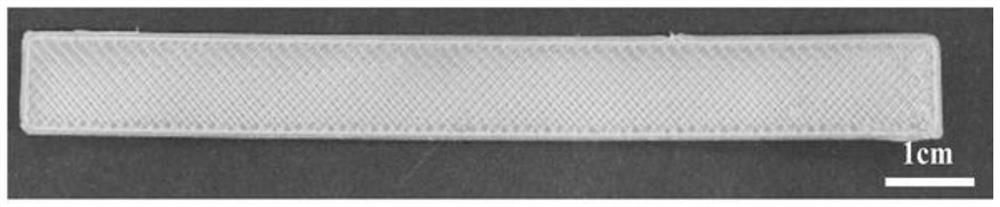

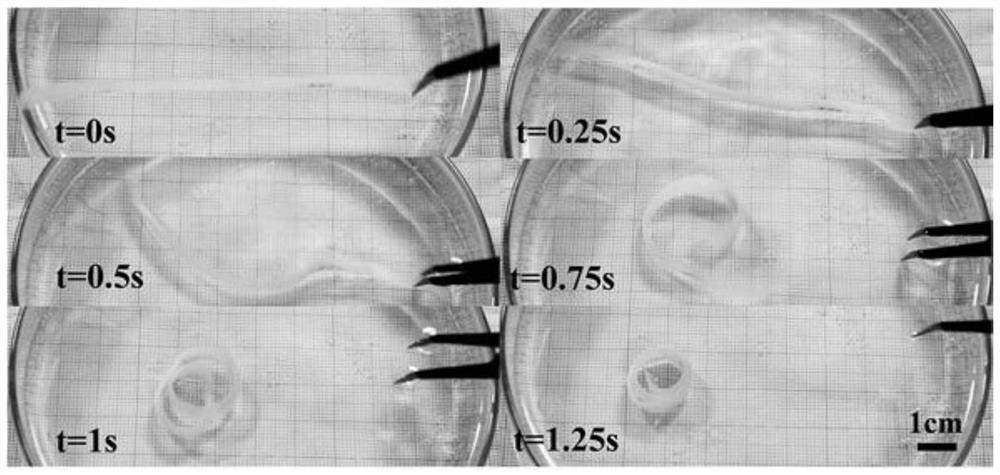

Preparation method of 3D printing shaping-free self-deforming shape memory intelligent material

ActiveCN112454889ASimple temporary shapeCumbersome processAdditive manufacturing apparatus3D object support structures3d printEngineering

The invention discloses a preparation method of a 3D printing shaping-free self-deforming shape memory intelligent material. The method comprises the steps that firstly, the structure of the materialis designed, and three-dimensional modeling is conducted on the material by using Solidworks; secondly, the model is sliced according to the design, and an STL format file is generated by means of conversion; thirdly, the STL format file is input into a 3D printing system, a printing path and 3D printing parameters are set, and the interlayer crossing angle is 0-180 degrees; fourthly, a fused deposition modeling process is adopted, wherein a printing extrusion head and a bottom plate are restored to zero positions firstly, the height of the extrusion head is finely adjusted, the distance between the extrusion head and the bottom plate is adjusted to be 0.2mm-0.6mm, so that extrusion wires are pre-stretched when the material is subjected to 3D printing, the prestress is stored in the material due to the limitation of the bottom plate or a bonding layer, and the temporary shape of the material can be fixed; fifthly, printing is conducted; and sixthly, the printed material is heated to reach temperature higher than glass-transition temperature; According to the preparation method, high-precision shaping can be realized, and multi-mode and diversified self-deformation can be realized.

Owner:JILIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com