Method for preparing sodium carbonate and sodium hydroxide by mirabilite liquid circulation

A liquid phase circulation, Glauber's salt technology, applied in chemical instruments and methods, alkali metal compounds, alkali metal carbonates, etc., can solve the problems of low utilization rate, complex equipment, difficult waste liquid treatment, etc. The effect of reducing and simplifying the recovery process of intermediate substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

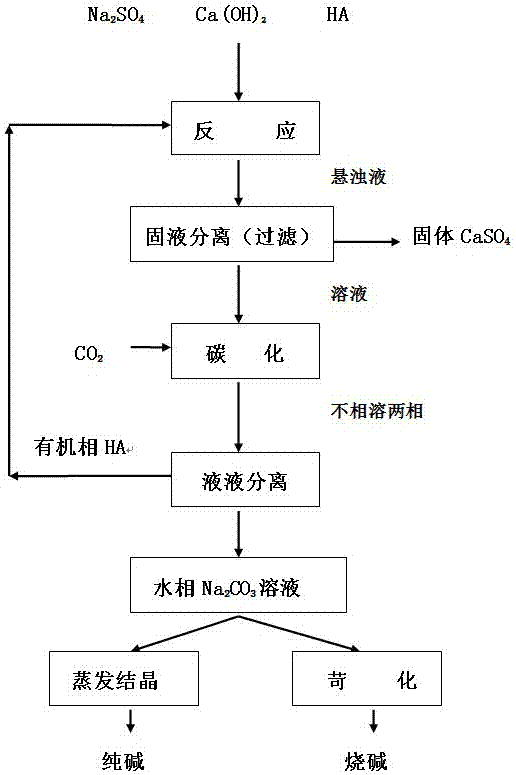

[0051] A kind of method for preparing soda ash and caustic soda by mirabilite liquid phase circulation method, such as figure 1 As shown, Glauber's salt 12g, water 50g, calcium oxide 6.4g, intermediate substance cresol 25g, normal pressure, reaction temperature 20°C, fully stirred, reaction time 0.5h. After the reaction is over. The calcium sulfate precipitate was separated by filtration to obtain the intermediate substance cresol sodium salt, the measured concentration was 1.24 mol / L, and the conversion rate of Glauber's salt was 91%.

[0052] Introduce carbon dioxide (content ≥ 99%) into the intermediate substance cresol sodium salt, control the carbonization temperature at room temperature, and control the carbon dioxide pressure at about 0.09M Pa. When the pH of the solution is 10, the reaction is stopped, and the carbonization solution is allowed to stand and separate into layers. Separate 25g of cresol, an intermediate substance, and add to the first step reaction for r...

Embodiment 2

[0054] A kind of method for preparing soda ash and caustic soda by mirabilite liquid phase circulation method, such as figure 1 As shown, Glauber's salt 12g, water 50g, calcium oxide 9.6g, intermediate substance cresol 36g, normal pressure, reaction temperature 70°C, fully stirred, reaction time 1h. After the reaction is over. The calcium sulfate precipitate was separated by filtration to obtain the intermediate substance cresol sodium salt, the measured concentration was 2.14 mol / L, and the conversion rate of mirabilite was 95%.

[0055] Introduce carbon dioxide (content ≥ 99%) into the intermediate substance cresol sodium salt, control the carbonization temperature at room temperature, and control the carbon dioxide pressure at about 0.09M Pa. When the pH of the solution is 10, the reaction is stopped, and the carbonization solution is allowed to stand and separate into layers. Separate the intermediate substance cresol 36g and add to the first step reaction for recycling. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com