A method for producing, separating and extracting L-glutamine

A kind of glutamine and the obtained technology are applied in the field of L-glutamine production to achieve high oxygen solubility and improve the effect of fermentation yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A method for producing, separating and extracting L-glutamine, comprising the steps of:

[0033] Step 1) Fermentation: Corynebacterium glutamicum GM34 was used as the strain, see "Response Surface Method Optimization of L-Glutamine Fermentation Medium, Biotechnology Communications 2013".

[0034] Corynebacterium glutamicum seed solution (OD 600nm 13.1) Inoculate 10% inoculum into a 100L fermenter containing 50L fermentation medium, and the fermentation time is 48h; the fermentation time is divided into two stages, the first stage is 0-24h, and the fermentation temperature is 32°C. Add ammonia water to control the pH at 5.0; the second stage is 24-48h, the fermentation temperature is 32°C, and the pH is controlled at 7.0 by adding ammonia water. After the second stage is completed, the L-glutamine fermentation broth is obtained;

[0035] When the fermentation lasts to 24 hours, add the promoting solution to the fermentation medium at a rate of 0.05ml / min.L (0.05ml per m...

Embodiment 2

[0047] A method for producing, separating and extracting L-glutamine, comprising the steps of:

[0048] Corynebacterium glutamicum seed solution (OD 600nm 13.4) Inoculate 9% inoculum into a 100L fermenter containing 50L fermentation medium, and the fermentation time is 48h; the fermentation time is divided into two stages, the first stage is 0-24h, and the fermentation temperature is 32℃ Add ammonia water to control the pH at 5.0; the second stage is 24-48h, the fermentation temperature is 32°C, control the pH at 7.0 by adding ammonia water, and collect the fermentation broth after the second stage is completed;

[0049] When the fermentation lasts for 24 hours, add the promoting solution to the fermentation medium at a rate of 0.07ml / min.L (0.07ml per minute per liter of fermentation broth) until the end of fermentation;

[0050] During the whole fermentation process, the stirring speed is controlled at 200rpm, the dissolved oxygen is controlled at 25%, and the glucose conce...

Embodiment 3

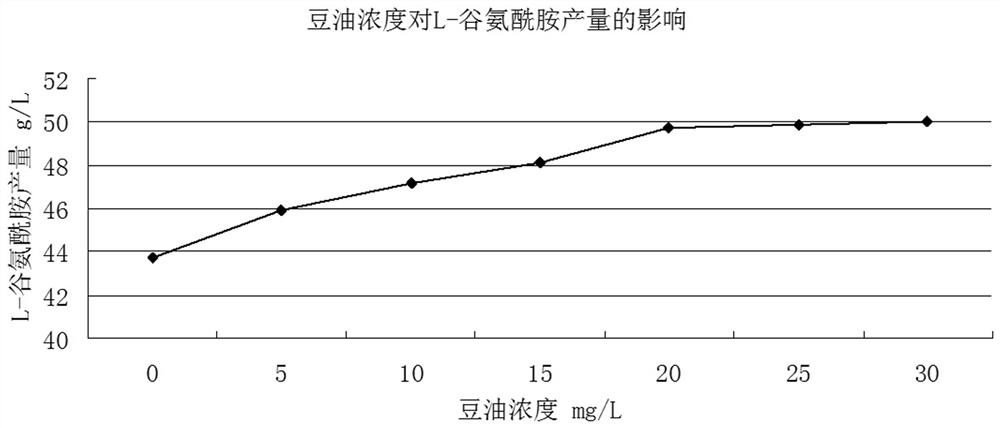

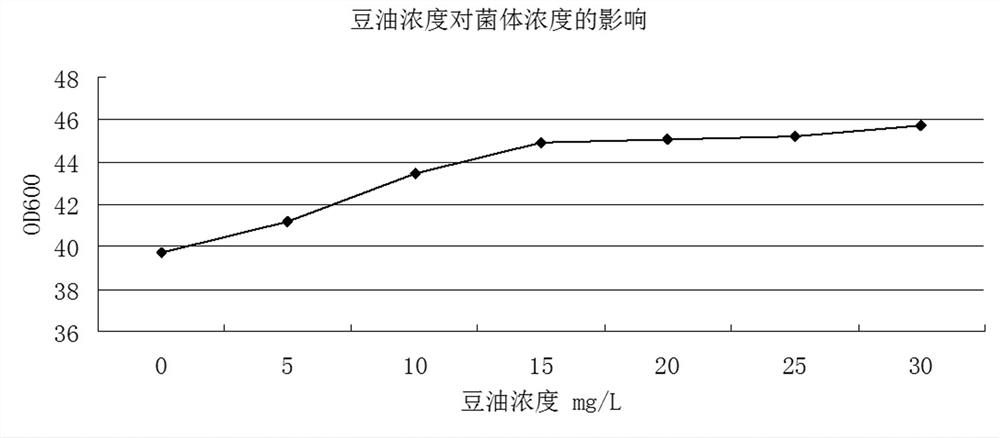

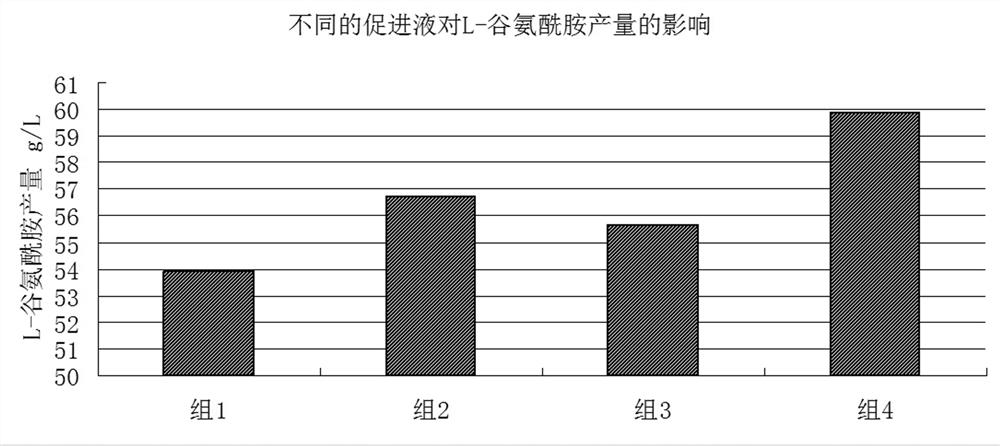

[0061] 1. On the basis of Comparative Example 1, the effect of soybean oil addition in the fermentation medium on the production of L-glutamine was studied. Set the concentration of soybean oil to 0, 5, 10, 15, 20, 25, 30 respectively, the unit is ml / L, such as Figure 1-2 As shown, as the concentration of soybean oil increases, the concentration of bacteria and the fermentation yield of L-glutamine also increase. When it increases to 15ml / L, the increase of L-glutamine begins to slow down, and the concentration of soybean oil reaches 20ml / L , the production of L-glutamine was close to the peak value, compared with when no soybean oil was added, the production of L-glutamine increased by 13.7%, and the concentration of bacteria increased by 6.5%; if the concentration of soybean oil continued to increase, the effect on L-glutamine was small ; During the aerobic fermentation of Corynebacterium glutamicum to produce L-glutamine, the oxygen transfer from the gas phase to the liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com