Strain and method for producing Welan gum

A technology of welan gum and bacterial strains, which is applied in the field of industrial microorganisms, can solve the problems of different production strains and fermentation processes, and achieve the effects of inhibiting degradation, simple process, and efficient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1 Sphingomonas provided by the invention Sphingomonas Morphological and physiological and biochemical identification of sp.WG strain

[0031] Sphingomonas WG provided by the invention ( Sphingomonas sp.WG) was isolated from the sea mud of Jiaozhou Bay, Qingdao, and the pure culture was obtained after serial dilution and plate plating. The strain morphology and physiological and biochemical reactions were identified by Gram staining, morphological observation, and Bojian Gram-negative bacteria identification system.

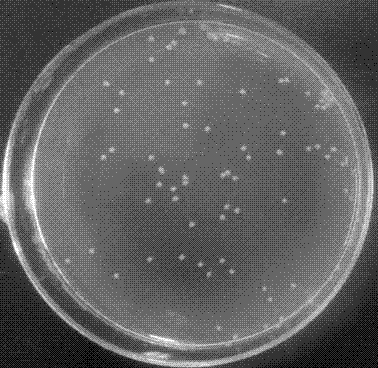

[0032] Sphingomonas WG ( Sphingomonas sp.WG) cultured on LB plates at 30°C for 24 hours to grow a single colony, the single colony was yellow, round, convex in the center, viscous, opaque, with neat edges and smooth surface (see attached figure 1 ); the strain is Gram-staining negative, the thallus is short rod-shaped, has flagella, and has no spores; its growth temperature is 20-40°C, growth pH is 4-9, and NaCl tolerance is 3%; oxidase, Arg...

Embodiment 2

[0033] Example 2 Sphingomonas WG provided by the invention ( Sphingomonas sp.WG) cloning and sequencing of the 16S rRNA gene

[0034] Sphingomonas WG provided by the invention ( Sphingomonassp.WG) 16S rRNA gene sequence characteristics: the WG strain was inoculated in LB medium, cultured at 30°C and 180 rpm for 16-18 h, and its genomic DNA was extracted using the Bacterial Genomic DNA Extraction Kit (Tiangen Biochemical Technology Co., Ltd.). The 16S rRNA gene fragment was obtained by PCR amplification using the upstream primer 5'-AGAGTTTGATCMTGGCTCAG-3' and the downstream primer 5'-TACGGYTACCTTGTTACGACTT-3'. The PCR conditions were as follows: 94°C for 5 min; 30 cycles of 94°C for 50 s, 56°C for 45 s, and 72°C for 90 s; 72°C for 10 min. After the 16S rRNA gene fragment obtained by PCR amplification was purified, it was connected to the pMD18-T vector with the quick connection kit, and the connection product was transformed into E. coli DH5α was screened on LB plates co...

Embodiment 3

[0035] Example 3 Preparation of seed solution

[0036] Solid medium: yeast extract 10 g / L, peptone 20 g / L, glucose 20 g / L, agar 20 g / L, pH7.5.

[0037] Liquid medium: yeast extract 10 g / L, peptone 20 g / L, glucose 20 g / L, pH 7.5.

[0038] The strain of Sphingomonas WG was streaked on YPD solid medium and cultured at a constant temperature of 30°C for 4 days to be activated. When yellow colonies grew, it was stored at 2-4°C for a short period of time until use. The activated single colony was transferred into a 250 ml Erlenmeyer flask filled with YPD liquid medium, and the volume of the Erlenmeyer flask was 50 ml. It was incubated at 30°C and the shaker speed was 230 rpm for 18 h to obtain the first-grade seed liquid. The primary seed liquid was inoculated into a 500 ml Erlenmeyer flask containing 100 ml liquid YPD medium at a 1.5% inoculation amount, and incubated at 30°C for 15 h at a shaker speed of 230 rpm to obtain a secondary seed liquid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com