Method for improving pristinamycine fermentation output

A technology of punamycin and production, which is applied in the field of microbial engineering, can solve the problems of high production cost and difficulty in further improving the fermentation level of punamycin, and achieve the effects of reducing production cost, increasing production and alleviating inhibition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

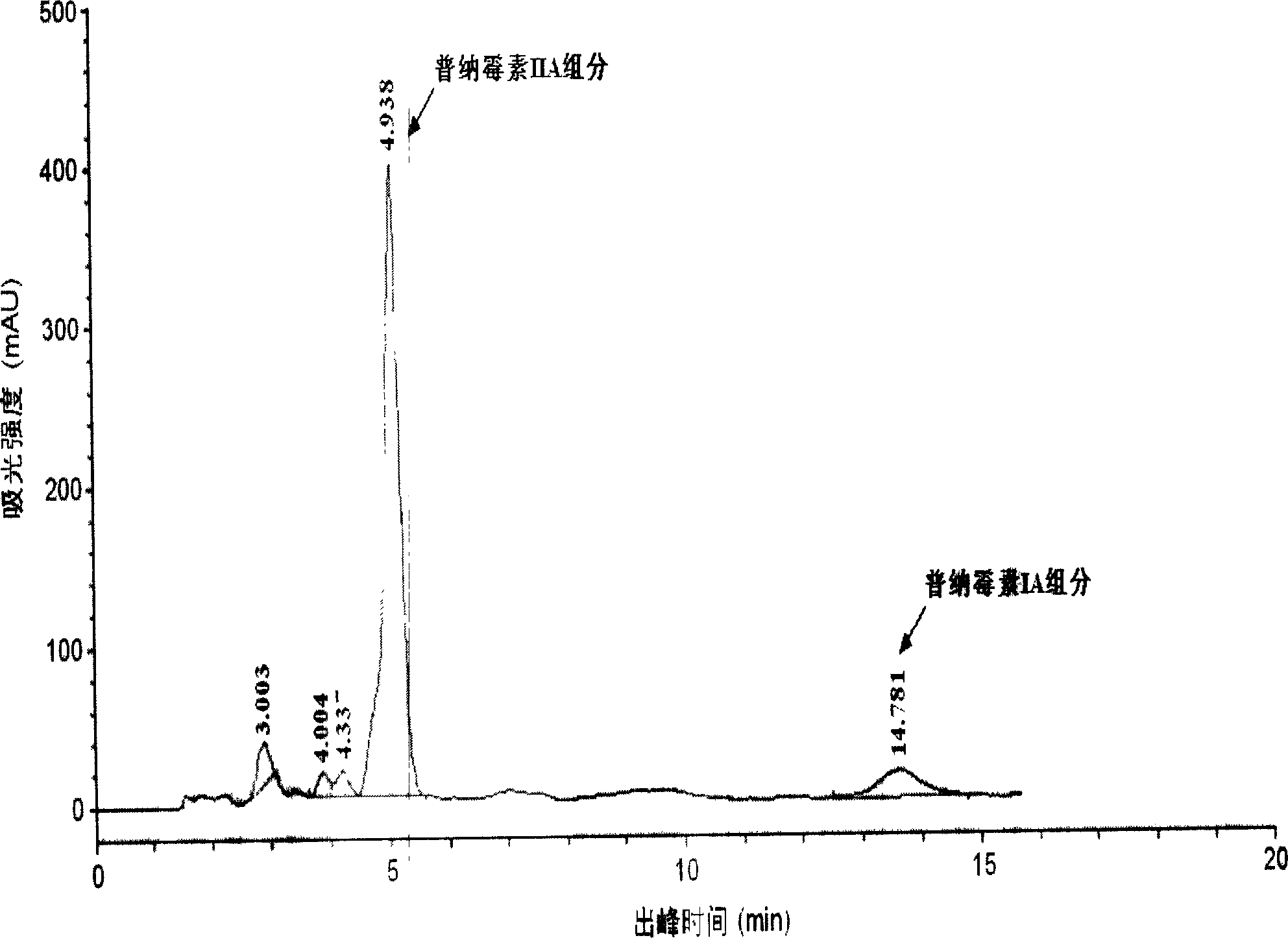

[0022] Embodiment 1: add macroporous adsorption resin fermentation production prunamycin new technology in shake flask

[0023]The cultivated mature Streptomyces spore culture was inoculated into an Erlenmeyer flask containing 25 milliliters of seed medium with the method of digging (the size of the digging block was 1 × 1 square centimeter), placed in a shaker for shaking and culturing for 36 hours, The rotating speed of the shaker was set at 220 rpm, and the culture temperature was 28°C. When the concentration of the mycelia of Streptomyces involutes in the seed liquid reached 20%, the culture was terminated. Inoculate 1.5 milliliters of seed liquid into an Erlenmeyer flask containing 25 milliliters of fermentation medium, place it in a shaker for shaking culture, set the speed of the shaker at 250 rpm, and the culture temperature at 28°C. hour, directly add the sterilized HZ-802 macroporous adsorption resin into the fermentation broth, the amount of resin added is 2.1g wet ...

Embodiment 2

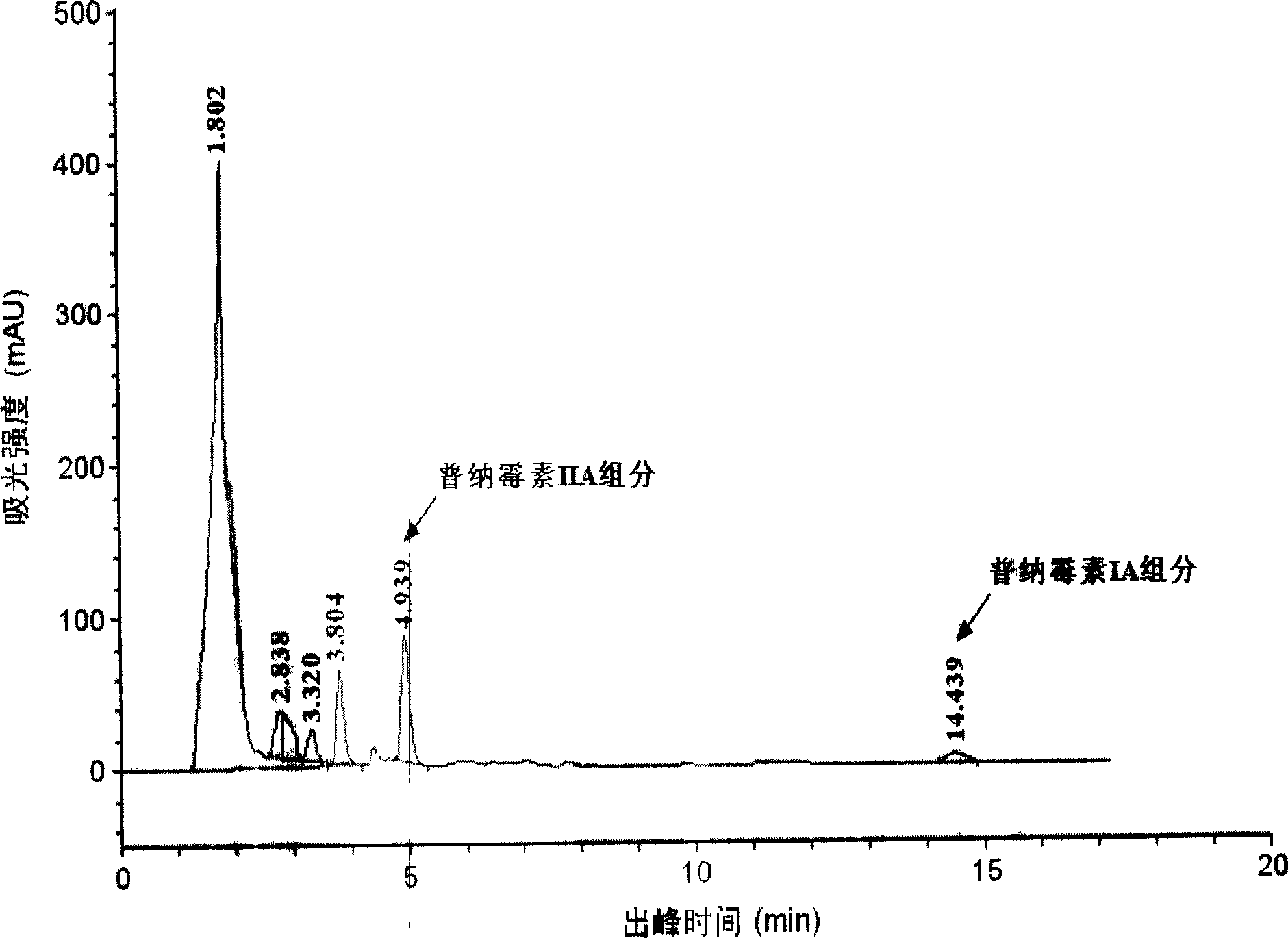

[0024] Embodiment 2: in 5 liters of fermentors, add macroporous adsorption resin and ferment and produce prunamycin new technology

[0025] 180 milliliters of seed liquids are inoculated into 5 liters of fermentors containing 3 liters of fermentation medium, and fermented. In the fermentors, feed sterile compressed air with a ventilation rate of 1.2 liters / (min × liters), and a stirring speed of 200 rev / min), the temperature is controlled at 28°C. When the fermentation was carried out to the 18th hour, the sterilized HZ-802 macroporous adsorption resin was added to the fermenter by flame method, and the amount of resin added was 150 grams of wet weight; then when the fermentation continued to the 25th hour , and then add 150 grams of HZ-802 wet resin by flame method, and ferment until the end of the 63rd hour. Filter and isolate the adsorption resin in the fermented liquid, use 1200 milliliters of concentration as the acetone solution of 70% to elute twice step by step, combi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com