Application of fucoidan in preparation of intestinal prebiotics

A fucoid oligosaccharide and prebiotic technology, applied in the biological field, can solve problems such as research on the function of unfuco oligosaccharides, and achieve the effects of reducing membrane transport function, reducing disease infection, and promoting the production of short-chain fatty acids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1, the preparation of microbial exopolysaccharide (EPS)

[0031] EPS is fermented and produced by Kosakonia sp.CCTCC M2018092 strain under fed-batch conditions. The specific steps are as follows: take Kosakonia sp.CCTCC M2018092 strain and culture it in a 250mL shake flask containing 30mL medium at 30°C and 200rpm for 20 hours , and then 30ml of bacterial culture solution was transferred to a 15L size fermenter at 30°C and 300rpm for pre-growth culture for 13 hours (air flow 1.5m 3 / h). Afterwards, get the bacterial liquid of 3L pre-growth and transfer in the 50L fermenter (containing 30L medium) and carry out fed-batch fermentation. Use peristaltic pump according to residual sugar amount to begin to add the glucose solution of 200g / L in batches with the speed of 0.9-3.8rpm after fermentation begins 13h. The ventilation volume of the fermenter is 1.5m 3 / h, the dissolved oxygen concentration is controlled above 10% by automatically adjusting the speed (300...

Embodiment 2

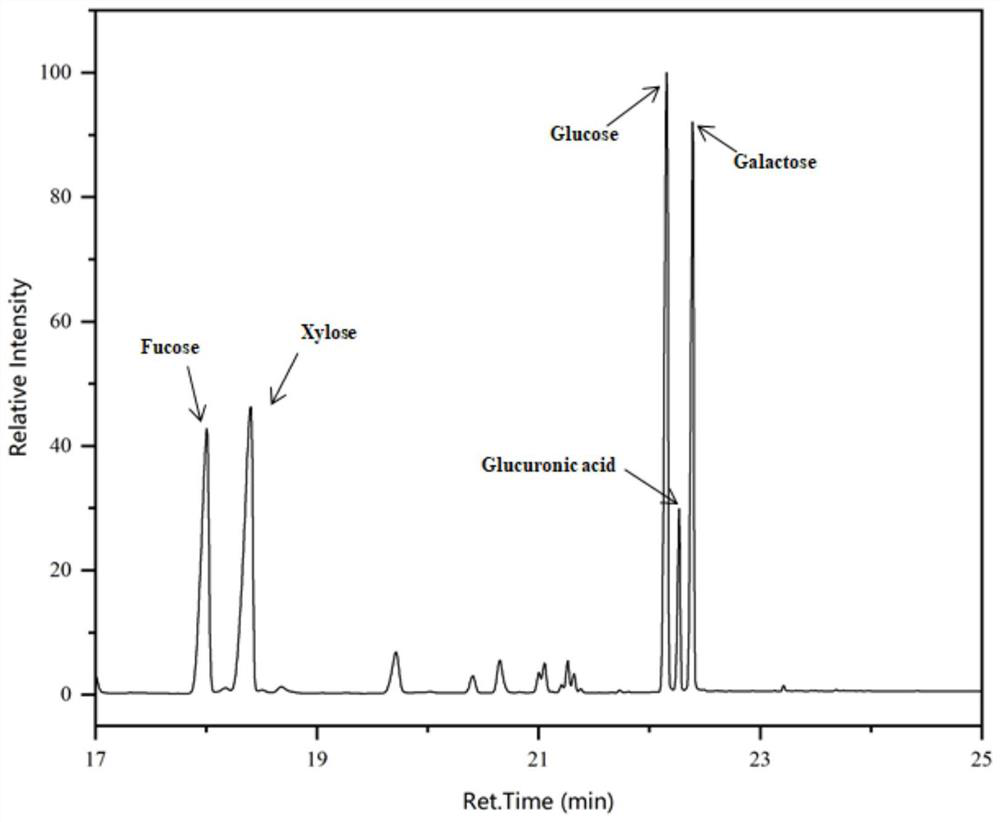

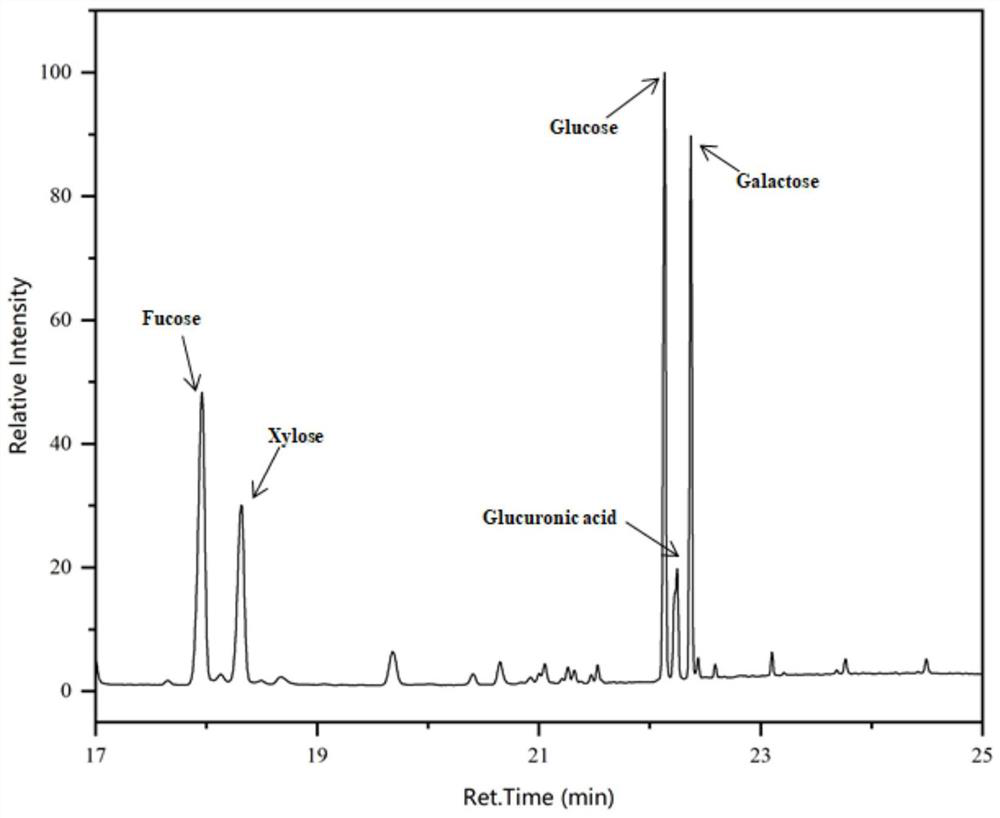

[0037] Embodiment 2, preparation of low molecular weight fucoidal oligosaccharides

[0038] The hydrolyzed polysaccharide prepared in Example 1 was dissolved in deionized water to prepare a polysaccharide aqueous solution with a mass fraction of 5%, and trifluoroacetic acid was added to make the final concentration 0.1M, and hydrolyzed in an oil bath at 100°C for 0.5h, 1h, 1.5h, After 2h and 3h, the obtained polysaccharide hydrolyzate was removed by using a 200Da nanofiltration membrane to remove trifluoroacetic acid, concentrated to a small volume by rotary evaporation at 40°C, and freeze-dried to obtain an oligosaccharide sample. The molecular weight was determined by high performance liquid chromatography. The chromatographic column was G3000PWXL. The column temperature is 40°C, and the mobile phase is 0.1M NaNO 3, the injection volume was 15 μl, and the results are shown in Table 1. The results show that the extraction rate of fucoid oligosaccharides removed from trifluor...

Embodiment 3

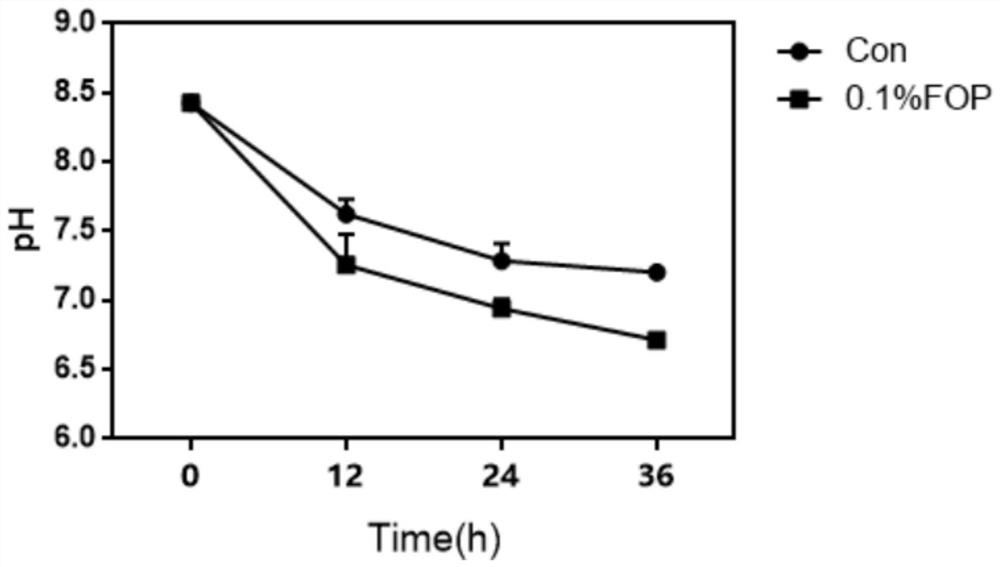

[0044] Example 3, test tube simulated intestinal fermentation of fucoidal oligosaccharides

[0045] Take 1L of fermentation medium, the medium components are as follows: peptone 2g / L; yeast extract 2g / L; NaCl 0.1g / L; K 2 HPO 4 0.04g / L; KH 2 PO 4 0.04g / L; MgSO 4 ·7H 2 O 0.01g / L; CaCl 2 ·6H 2 O 0.01g / L; NaHCO 3 2g / L; Tween 80 2mL / L, add heme at 0.02g / L after sterilization; 10mL / L vitamin K 1 ; 0.5g / L bile salt; 0.5g / L cysteine hydrochloride, adding fucoidal oligosaccharides by mass fraction 0.1%.

[0046] First put 6 test tubes into 25ml culture medium, inoculate with 10% fecal bacteria liquid, and pass through anaerobic gas for 5min (85%N 2 , 10% CO 2 , 5%H 2 ), and seal with paraffin liquid, take a sample every 12h, measure the pH and gas of the fermentation broth, the results are as follows image 3 shown. The results showed that the pH drop rate of the fermentation broth added with 0.1% fucoidal oligosaccharide was higher than that of the control group.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com