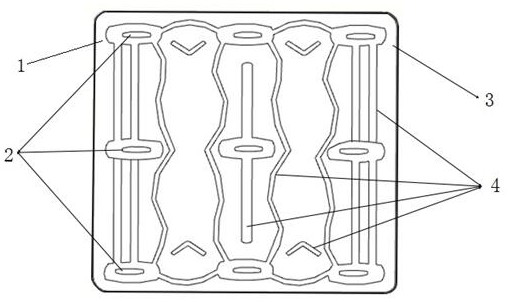

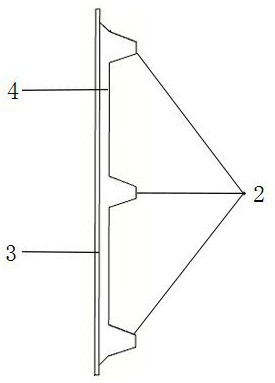

Artificial composite tray for logistics and preparation method thereof

A pallet and artificial technology, which is applied in the field of artificial composite pallets for logistics and its preparation, can solve the problems of high transportation cost, large space occupation, and high pallet manufacturing cost, so as to reduce the manufacturing cost, reduce the space occupation, and save the transportation cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

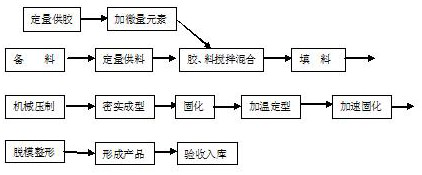

Method used

Image

Examples

Embodiment 1

[0039] An artificial composite tray for logistics, the shape of the tray is as above, and the tray is prepared from the following raw materials in parts by weight:

[0040] 20 parts of crushed straw, 10 parts of sawdust, 10 parts of sawdust, and 30 parts of modified urea-formaldehyde resin glue.

[0041] A method for preparing an artificial composite pallet for logistics, the pallet is as described above, comprising the following steps:

[0042] Step 1. Weigh the crushed straw, wood chips, sawdust and modified urea-formaldehyde resin glue into the mixer and stir evenly, add the mixed materials into the tray mold, and fasten the upper and lower molds;

[0043] Step 2. Apply a pressure of 200KN to the mold, and at the same time start the built-in heating device of the mold, heat up to 40°C, and keep it warm for 30 minutes;

[0044] Step 3: demoulding, shaping, drying, and warehousing to obtain the artificial composite pallet for logistics.

[0045] The modified urea-formaldehy...

Embodiment 2

[0053] An artificial composite tray for logistics, the shape of the tray is as above, and the tray is prepared from the following raw materials in parts by weight:

[0054] 30 parts of crushed straw, 20 parts of sawdust, 20 parts of sawdust, and 50 parts of modified urea-formaldehyde resin glue.

[0055] A method for preparing an artificial composite pallet for logistics, the pallet is as described above, comprising the following steps:

[0056] Step 1. Weigh the crushed straw, wood chips, sawdust and modified urea-formaldehyde resin glue into the mixer and stir evenly, add the mixed materials into the tray mold, and fasten the upper and lower molds;

[0057] Step 2. Apply a pressure of 500KN to the mold, and at the same time start the built-in heating device of the mold, heat up to 50°C, and keep it warm for 50 minutes;

[0058] Step 3: demoulding, shaping, drying, and warehousing to obtain the artificial composite pallet for logistics.

[0059] The modified urea-formaldehy...

Embodiment 3

[0067] An artificial composite tray for logistics, the shape of the tray is as above, and the tray is prepared from the following raw materials in parts by weight:

[0068] 26 parts of crushed straw, 15 parts of sawdust, 14 parts of sawdust, and 35 parts of modified urea-formaldehyde resin glue.

[0069] A method for preparing an artificial composite pallet for logistics, the pallet is as described above, comprising the following steps:

[0070] Step 1. Weigh the crushed straw, wood chips, sawdust and modified urea-formaldehyde resin glue into the mixer and stir evenly, add the mixed materials into the tray mold, and fasten the upper and lower molds;

[0071] Step 2. Apply a pressure of 300KN to the mold, and at the same time start the built-in heating device of the mold, heat up to 45°C, and keep it warm for 40 minutes;

[0072] Step 3: demoulding, shaping, drying, and warehousing to obtain the artificial composite pallet for logistics.

[0073] Preferably, the modified ure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com