Polyurethane hard foam brush type disintegrating machine

A technology of hard foam and polyurethane, which is applied in the fields of mechanical material recycling, plastic recycling, recycling technology, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

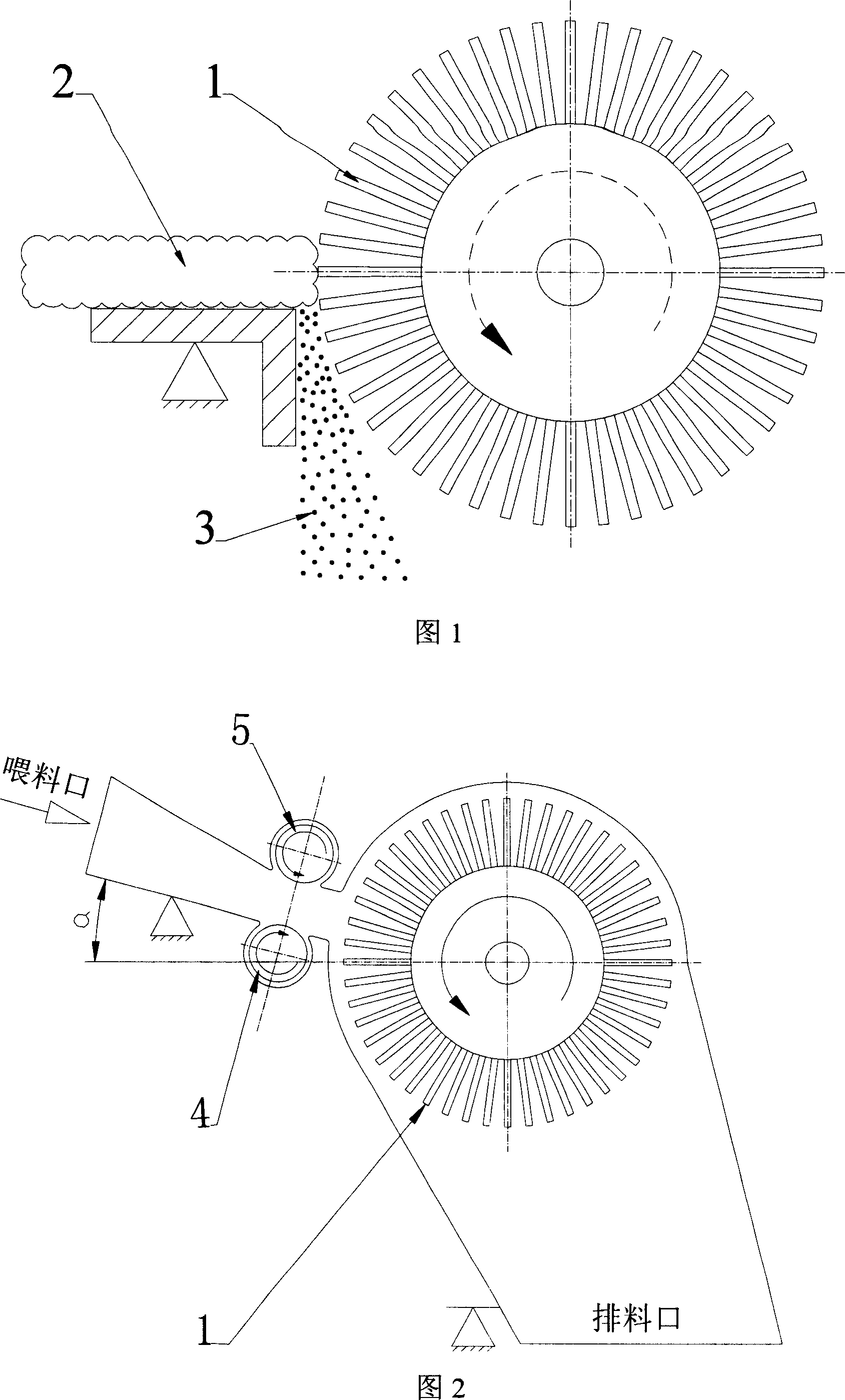

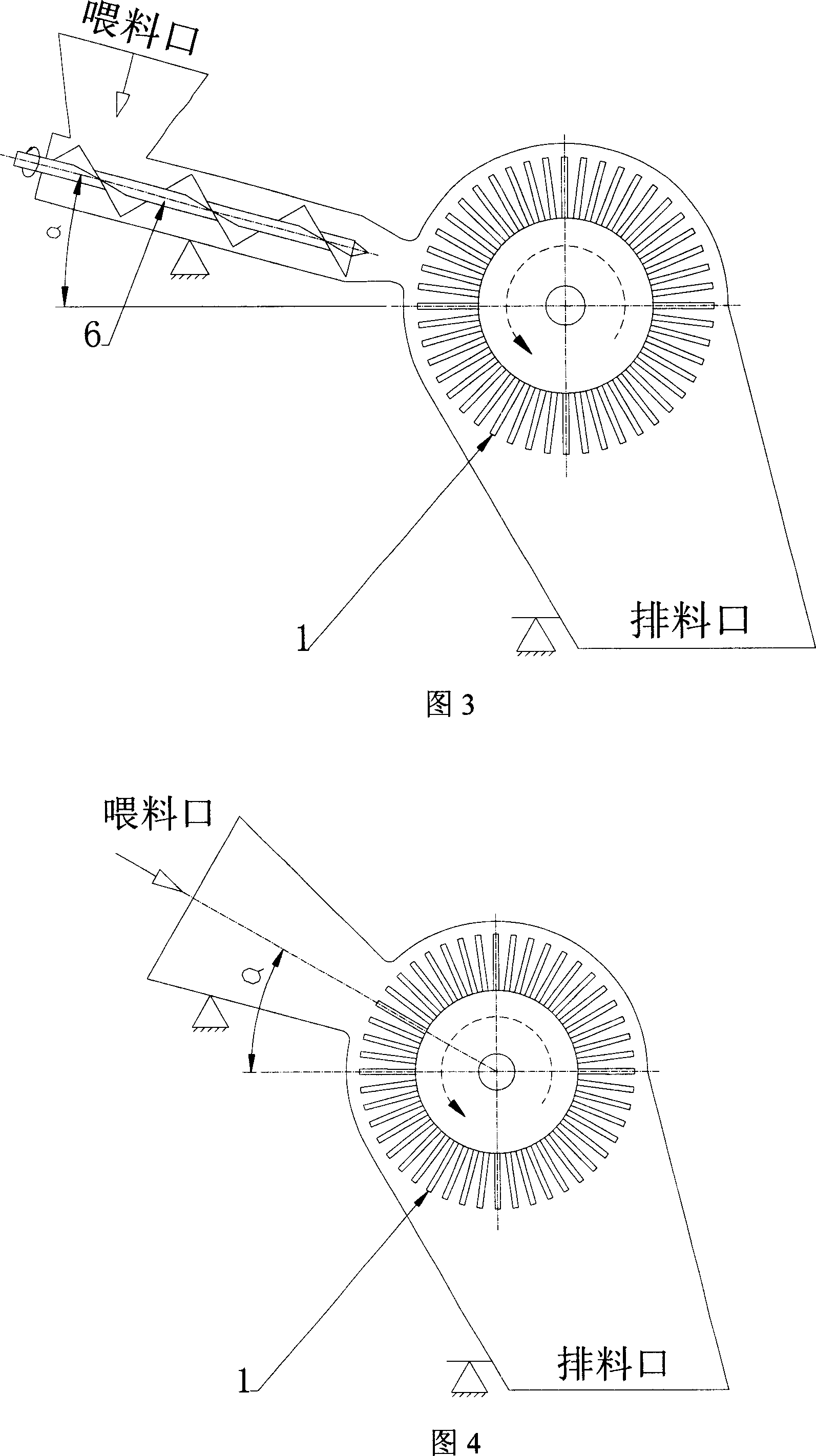

[0020] The pulverizer consists of a feeding device, a brush-type crushing wheel, and necessary racks and casings. Its structural principle is shown in Figure 1. 1 is the brush-type crushing wheel, 2 is the foam block to be crushed, and 3 is the powder after crushing. .

[0021] The brush crushing wheel consists of a hub and radially distributed filamentary crushing bodies. The diameter of the hub is between 1 mm and 20,000 mm, and the axial length is between 1 mm and 20,000 mm. The diameter and length are determined according to different process requirements. Filamentous broken bodies are made of metal wire or non-metallic wire, with a diameter between 0.05 mm and 100 mm and a length between 0.01 mm and 10,000 mm. The filiform broken bodies are radially distributed on the outside of the wheel rim. The quantity is determined according to the crushing process. The brush-type crushing wheel can be an integral structure or an assembled structure. The entire brush-type crushing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Axial length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com