Method of reducing area covered by vibrating sieve and vibrating sieve

A vibrating sieve and sieve box technology, which is applied to chemical instruments and methods, sieving, solid separation, etc., can solve the problems of inability to carry out equipment transformation, small space of vibrating sieve, increase equipment investment, etc., so as not to affect the screening efficiency and screening accuracy, reduce equipment installation land, and ensure the effect of environmental protection requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

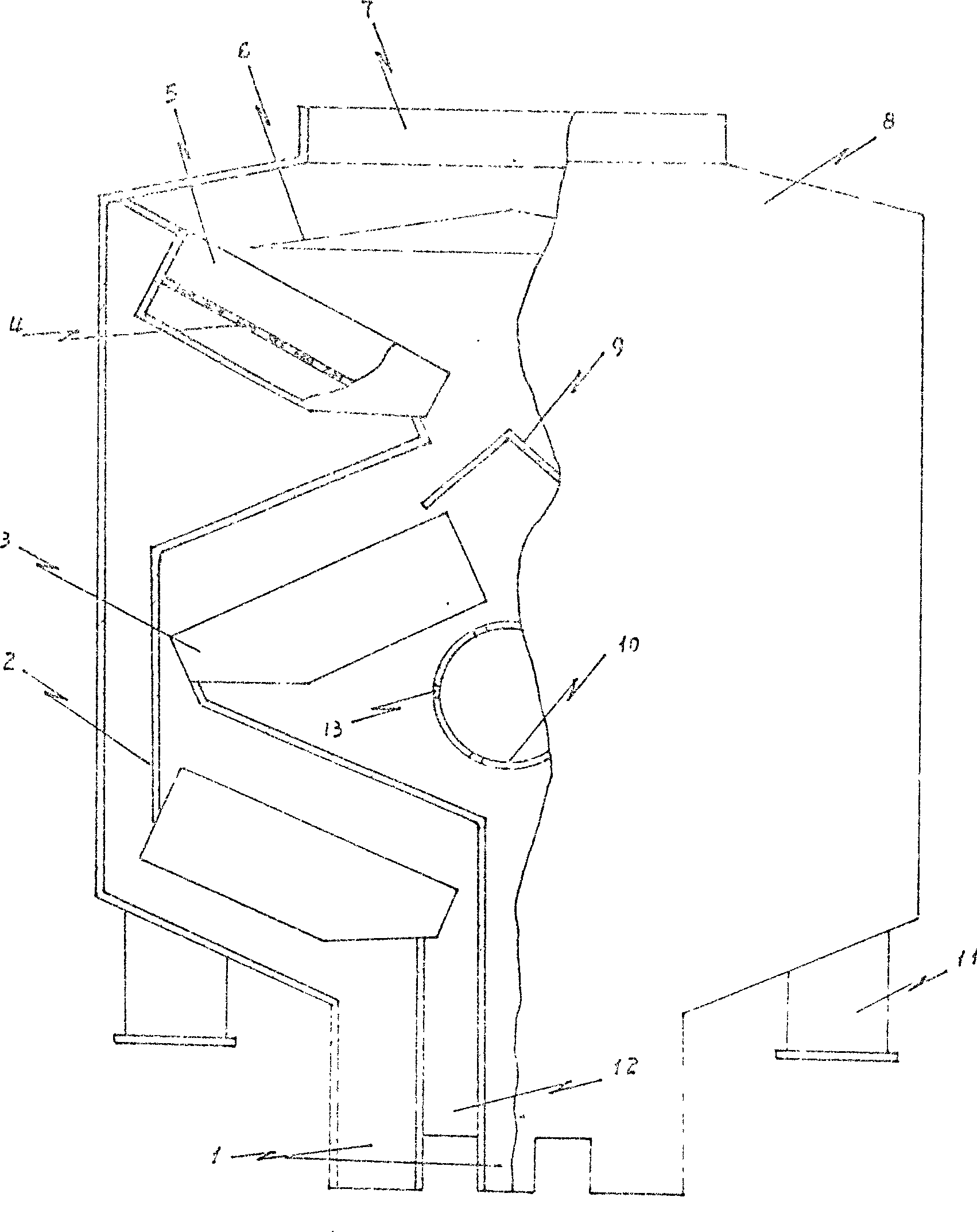

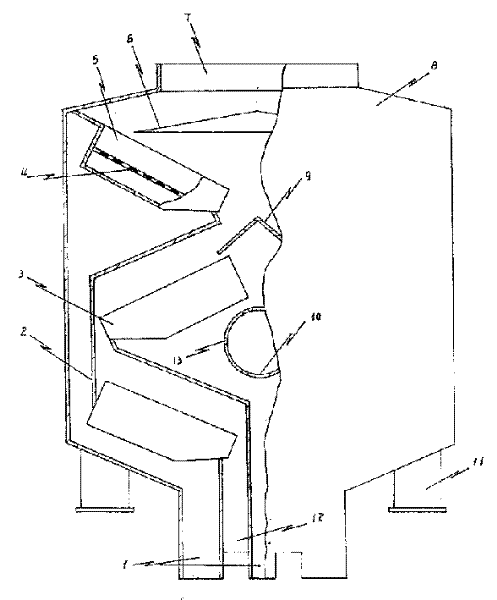

[0008] In order to clearly illustrate the technical features of the solution, the solution will be described below through a specific implementation mode combined with the accompanying drawings.

[0009] As can be seen from the accompanying drawings, the vibrating screen of this program takes up less land, mainly including a feed port 7, an under-sieve material outlet 1, an over-sieve material outlet 12, a distributor 6, and a sieve plate 5 and a sieve surface. The screen box 8 of a plurality of unit screens 3 composed of 4, and the excitation source 11 connected with the screen box 8 is characterized in that the plurality of unit screens 3 are arranged up and down in the screen box 8, and the tail, The heads are arranged in a Z-shape from top to bottom.

[0010] A kind of vibrating screen processed by the method of vibrating screen occupying less land, mainly including a feed port 7, a sieve material outlet 1, a sieve material outlet 12, a distributor 6 and a sieve plate 5 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com