Device and process for producing power plant fuel with coal precipitation plant coal slime slurry

A technology of coal slurry and coal preparation plant, which is applied in the field of equipment for producing power plant fuel from coal slurry slurry in coal preparation plants. It can solve the problems of long production and processing period, high operating cost, dust pollution, etc., and reduce construction investment and production cost. Reduce work intensity and ensure the effect of environmental protection requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

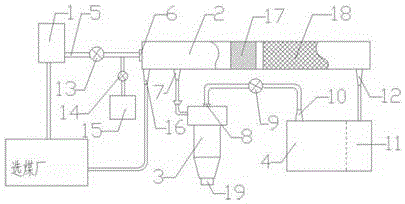

[0031]A device for producing power plant fuel with coal slurry in a coal preparation plant, including a coal slurry buffer pool 1, a flocculant tank 15, a horizontal screw centrifugal drying integrated machine 2, a gas-solid separator 3, and a power plant boiler 4; the coal slurry buffer The pool 1 is connected to the feed port 6 of the decanter centrifugal dryer 2 through the feed pipe 5, and the gas mixed dry material outlet 7 on the decanter centrifugal dryer 2 is connected to the gas-solid separator 3 through the pipeline, and the gas-solid separation The gas outlet 8 at the upper end of the device 3 is connected to the feedback gas inlet 10 of the power plant boiler 4 through the pipeline and the exhaust fan 9, and the vertical shaft flue 11 in the power plant boiler 4 is connected to the high-temperature gas inlet 12 on the decanter centrifugal drying integrated machine 2, The flocculant tank 15 is connected to the feed pipe 5 through the flocculant metering pump 14; the ...

Embodiment 2

[0038] A device for producing power plant fuel with coal slurry in a coal preparation plant, including a coal slurry buffer pool 1, a flocculant tank 15, a horizontal screw centrifugal drying integrated machine 2, a gas-solid separator 3, and a power plant boiler 4; the coal slurry buffer The pool 1 is connected to the feed port 6 of the decanter centrifugal dryer 2 through the feed pipe 5, and the gas mixed dry material outlet 7 on the decanter centrifugal dryer 2 is connected to the gas-solid separator 3 through the pipeline, and the gas-solid separation The gas outlet 8 at the upper end of the device 3 is connected to the feedback gas inlet 10 of the power plant boiler 4 through the pipeline and the exhaust fan 9, and the vertical shaft flue 11 in the power plant boiler 4 is connected to the high-temperature gas inlet 12 on the decanter centrifugal drying integrated machine 2, The flocculant tank 15 is connected to the feed pipe 5 through the flocculant metering pump 14; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com