Floor area required less vibrating screen

A vibrating screen and screen box technology, which is applied in the direction of filter screen, solid separation, grille, etc., can solve the problems that equipment transformation cannot be carried out, equipment investment is increased, and the space of vibrating screen is small, so as not to affect the screening efficiency and screening efficiency. Accuracy, reduce equipment installation land, reduce the effect of installation land

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] In order to clearly illustrate the technical features of the solution, the solution will be described below through a specific implementation.

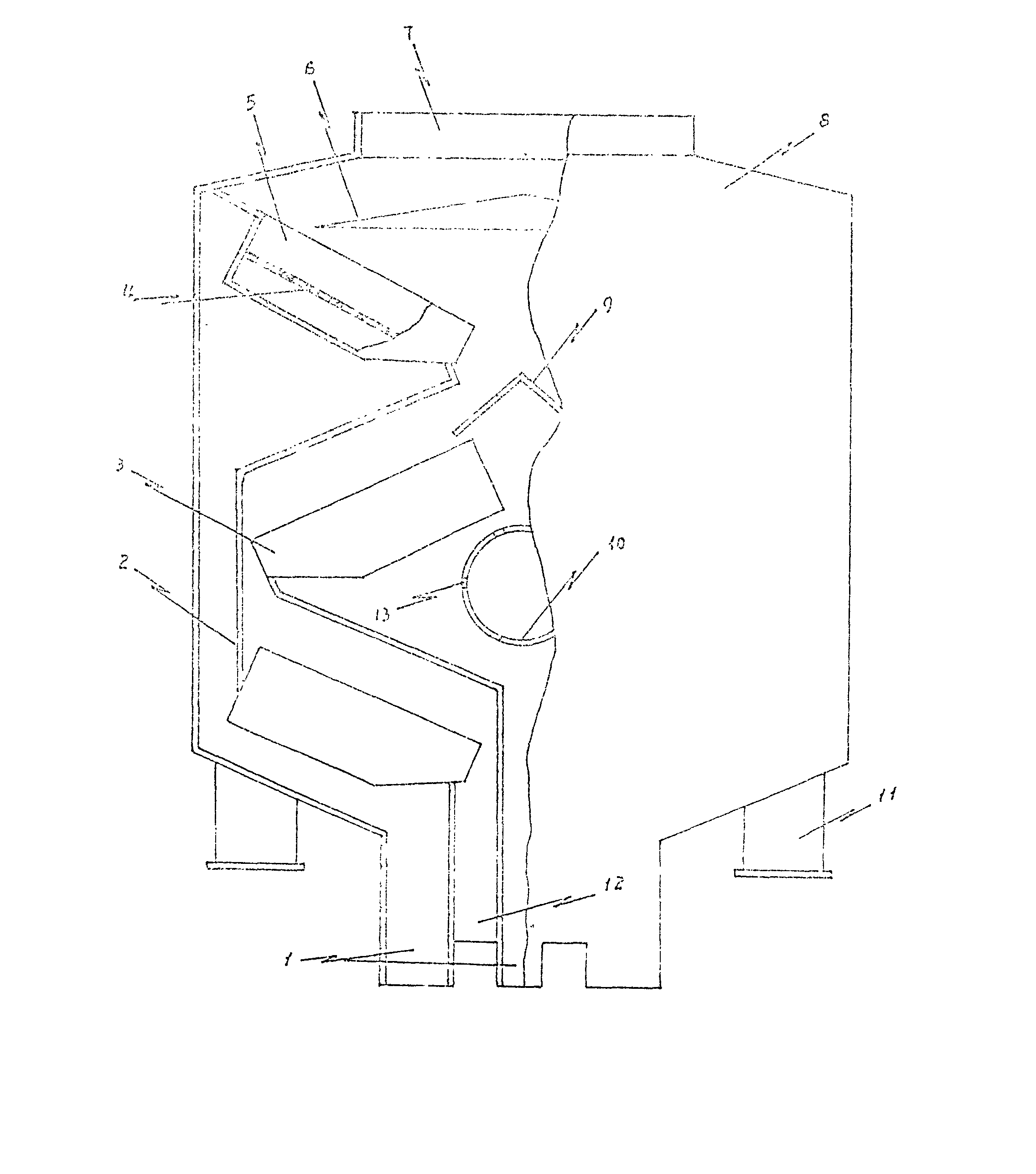

[0008] It can be seen from the accompanying drawings that the vibrating screen with less land occupation of this program mainly includes a feed inlet 7, an under-sieve material outlet 1, an over-sieve material outlet 12, a distributor 6, and a sieve plate 5 and a sieve surface 4. The sieve box 8 of a plurality of unit sieves 3 formed, and the excitation source 11 connected with the sieve box 8, this scheme is that the described plurality of unit sieves 3 are arranged up and down in the sieve box 8, and the tail and head Relative to the Z-shaped arrangement from top to bottom, the unit sieves 3 can be one group arranged up and down, or multiple groups arranged up and down. In this specific embodiment, three unit sieves 3 are arranged up and down as one There are two groups arranged corresponding to each other, and there is a par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com