Efficient production method of bromhexine hydrochloride

A technology of bromhexine hydrochloride and its production method, which is applied in the production field of bromhexine hydrochloride, can solve the problems of high production cost, low yield, non-environmental protection, etc., achieve the improvement of purity and yield, reduce reaction temperature, and reduce consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

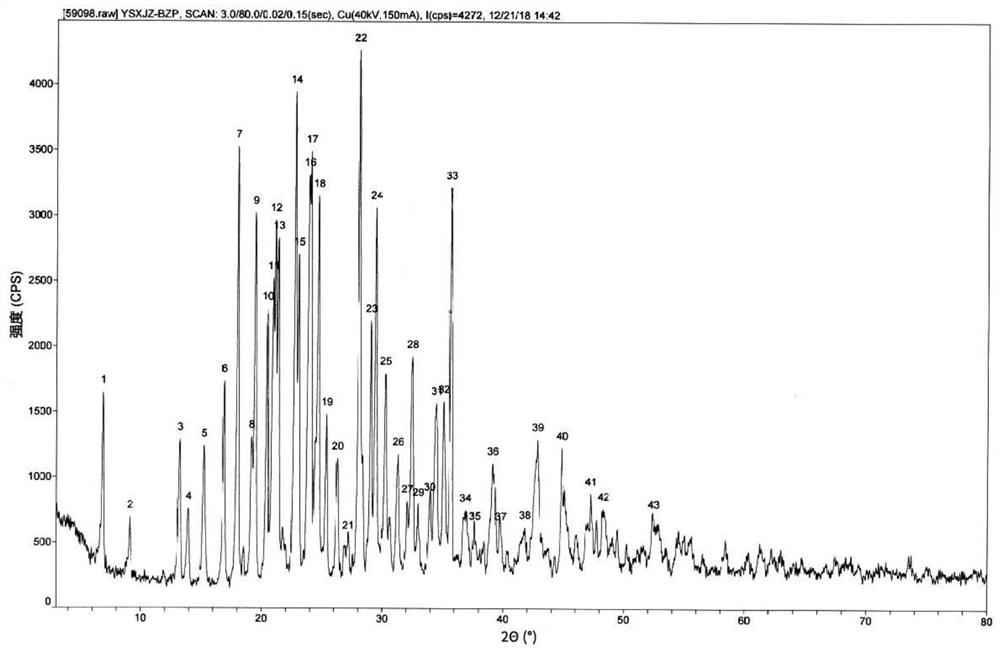

Embodiment 1

[0081] Embodiment 1 (new process)

[0082] 1, Preparation of 3,5-dibromo-2-aminobenzyl alcohol

[0083]

[0084] Put 240kg of absolute ethanol and 100kg of 3,5-dibromo-2-aminobenzaldehyde into the cleaned and dried 1000L glass-lined reactor. After stirring evenly, slowly add 9 kg of potassium borohydride in 6 times to control the reaction temperature The reaction temperature was not higher than 50° C., stirred for 3 hours, and the reaction of the raw materials was checked by TLC. After the reaction is complete, the reaction solution is placed in a 2000L reactor and cooled to 0-10°C for crystallization. Put the clean centrifuge filter bag well, put the material into the centrifuge for spin filtration, wash the material with water until neutral (check with pH test paper), and spin dry. Put the dried intermediate into a clean stainless steel tray, spread it evenly, with a thickness of 1-2 cm, place it on the drying frame, push it into the hot air circulation oven, turn off t...

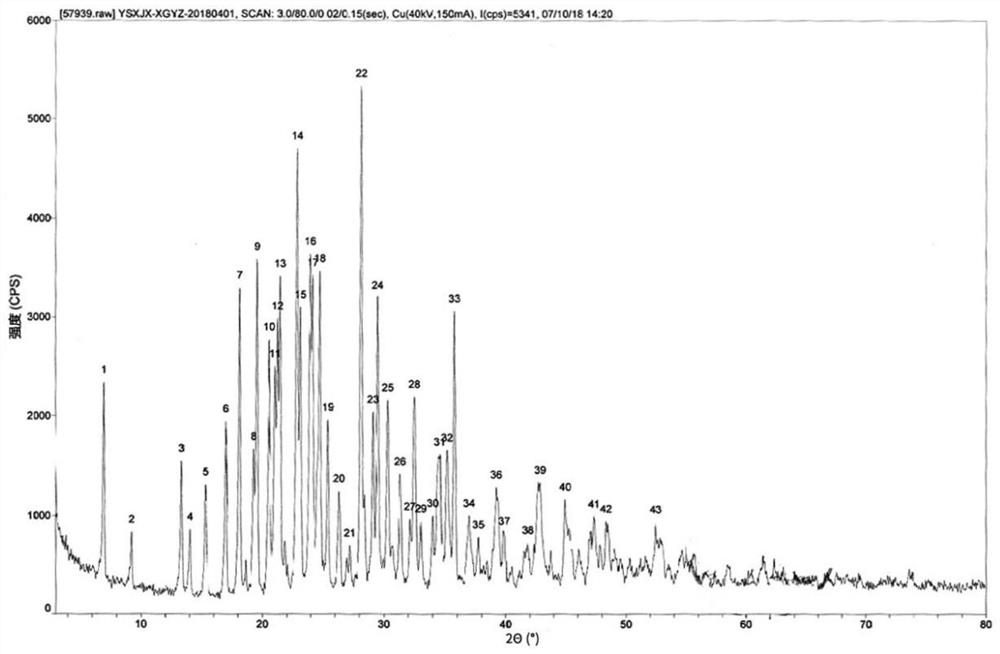

Embodiment 2

[0099] Embodiment 2 (new technology)

[0100] 1. Synthesis of 3,5-dibromo-2-aminobenzyl alcohol

[0101]

[0102] In the cleaned and dried 1000L glass-lined reactor, drop into 240kg of absolute ethanol, 3,5-dibromo-2-aminobenzaldehyde 100kg, after stirring evenly, slowly add potassium borohydride 12kg in 6 times, control the reaction temperature as 20° C., stirred for 3 hours, and TLC checked that the raw materials were completely reacted. After the reaction is complete, the reaction solution is placed in a 2000L reactor and cooled to 0-10°C for crystallization. Put the clean centrifuge filter bag well, put the material into the centrifuge for spin filtration, wash the material with water until neutral (check with pH test paper), and spin dry. Put the dried intermediate into a clean stainless steel tray, spread it evenly, with a thickness of 1-2cm, place it on the drying frame, push it into the hot air circulation oven, turn off the oven, turn on the power to heat up to 8...

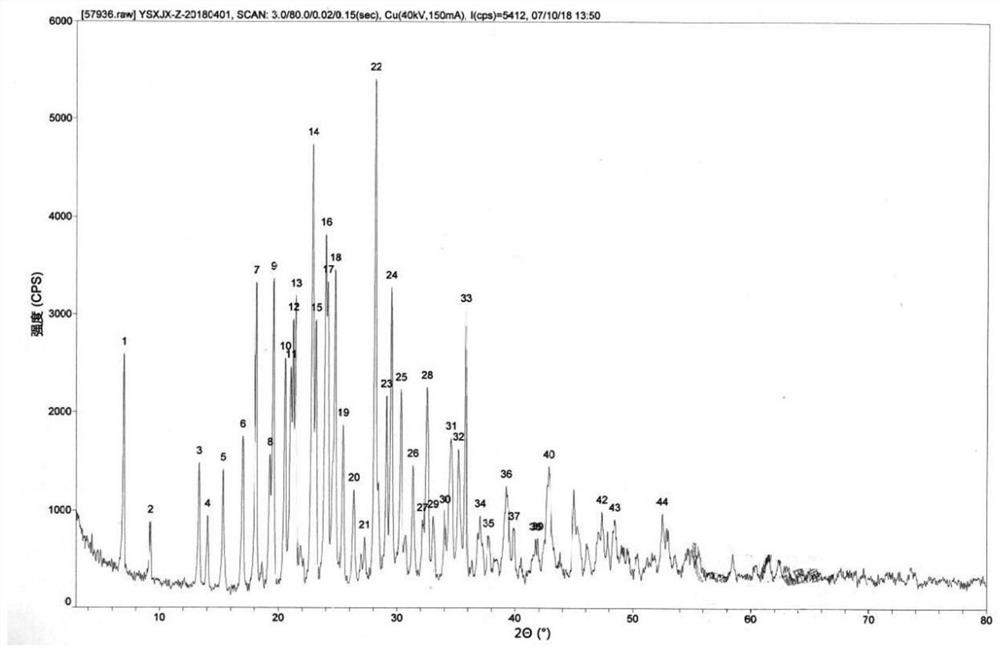

Embodiment 3

[0110] Embodiment 3 (new process)

[0111] 1. Synthesis of 3,5-dibromo-2-aminobenzyl alcohol

[0112]

[0113] In the cleaned and dried 1000L glass-lined reactor, drop into 240kg of dehydrated alcohol, 3,5-dibromo-2-aminobenzaldehyde 100kg, after stirring evenly, slowly add potassium borohydride 6kg in 6 times, control the reaction temperature as 60° C., stirred for 3 hours, and TLC checked that the reaction of the raw materials was complete. After the reaction is complete, the reaction solution is placed in a 2000L reactor and cooled to 0-10°C for crystallization. Put the clean centrifuge filter bag well, put the material into the centrifuge for spin filtration, wash the material with water until neutral (check with pH test paper), and spin dry. Put the dried intermediate into a clean stainless steel tray, spread it evenly, with a thickness of 1-2cm, place it on the drying frame, push it into the hot air circulation oven, turn off the oven, turn on the power to heat up t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com