Mounting structure and method of electrical cubicle

A technology of installation structure and installation method, applied in electrical components, substation/distribution device casing, substation/switch layout details, etc., can solve the problems of high construction intensity, large working space, hidden safety hazards, etc., and reduce the installation and operation space. , Easy to adjust the position, to ensure the effect of environmental protection requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

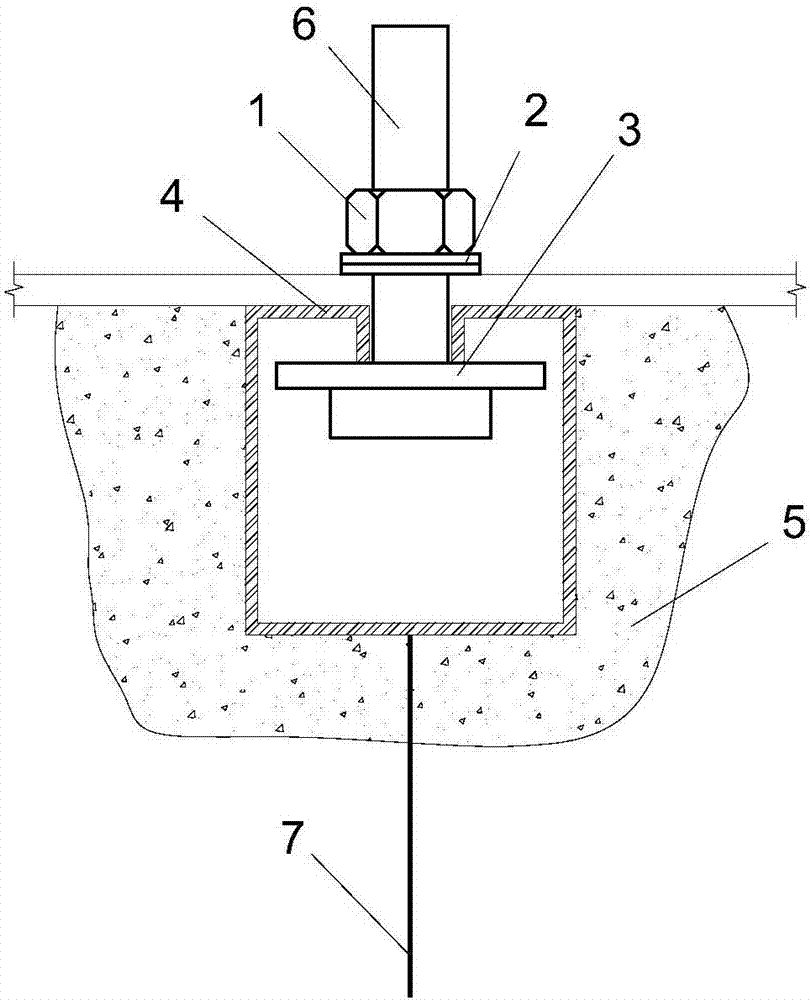

[0015] Such as figure 1 The installation structure of the electric screen cabinet of the present invention shown has a strip-shaped metal fixing part 4 for being arranged in the concrete 5. The strip-shaped metal fixing part 4 adopts C-shaped steel prefabricated in the factory, and is connected to the grounding structure through the anchor bar 7 grounding. The strip-shaped metal fixing part 4 is a hollow structure, and an opening is arranged on the upper end thereof along the axial direction. A threaded fastener 6 of a bolt structure protruding from the opening is provided in the hollow structure, and the length of the main body of the threaded fastener 6 is greater than the radial length of the strip metal fastener 4 . The protruding part of the threaded fastener 6 is provided with a nut 1 matched with it through a washer 2 . The bottom of the threaded fastener 6 is stuck on the lower edge of the opening of the strip metal fixing part 4 through the backing plate 3 .

[001...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com