WGGH (Water Gas Gas Heater) system

A No. 1, FGR technology, applied in the WGGH system field, can solve the problems of no energy saving, equipment waste, and low utilization rate, and achieve the effects of ensuring safety and no corrosion, huge economic benefits, and improving unit efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

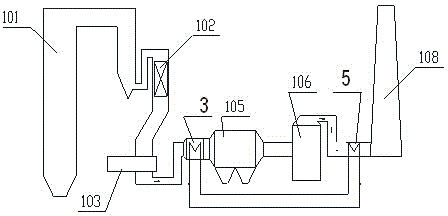

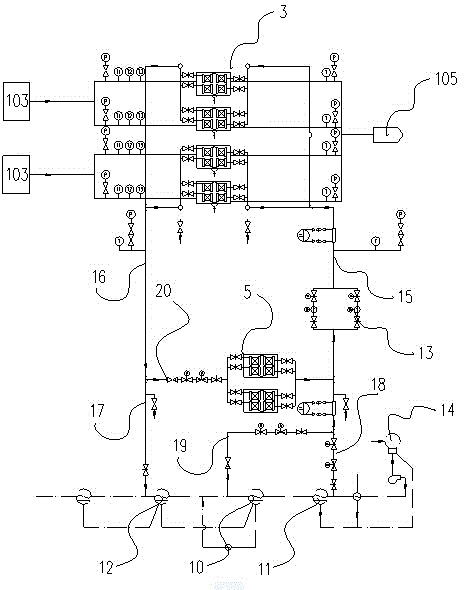

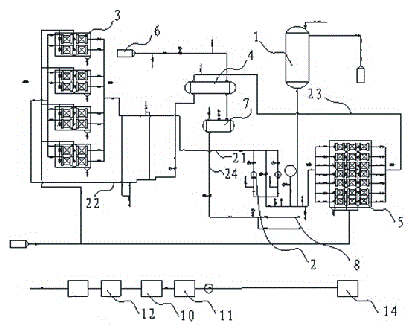

[0037] One, the arrangement of WGGH of the present invention:

[0038] Such as image 3 As shown, the WGGH system of the present invention includes FGC3, FGR5, two-point water intake circuit 19, return water circuit 17, circulating booster pump 13 and condensate water pipeline. FGC3 is connected to the rear end of the air preheater 103, the temperature of the flue gas coming out of the air preheater 103 is about 130 degrees, and the temperature required by the dust collector 105 behind the FGC3 is about 95 degrees, therefore, here, the FGC3 needs to put the flue gas that enters into it The flue gas temperature is reduced from about 130 degrees to about 95 degrees, and the corresponding flue gas temperature from the desulfurization tower in front of FGR5 is about 50 degrees, and the flue gas temperature required by the chimney is about 80 degrees. Therefore, FGR needs to enter The flue gas temperature in it rises from about 50 degrees to about 80 degrees. For this reason, F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com