Production technology of L-isoleucine

A production process, the technology of isoleucine, applied in the direction of microorganisms, preparation of organic compounds, methods based on microorganisms, etc., can solve the problems of poor filtration effect, large amount of activated carbon, and high cost, so as to reduce the amount of waste water, increase production, The effect of reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A kind of production technology of L-isoleucine, it comprises the steps:

[0034] Step 1) Fermentation: Using Corynebacterium glutamicum ATCC14309 as the experimental strain, Corynebacterium glutamicum seed solution (OD 600 The value is 12) According to the inoculation amount of 6%, transfer to a 50L fermenter containing 30L fermentation medium for cultivation, the temperature is 30°C, the cultivation time is 60 hours, and the pH of the medium is controlled by automatically adding 20% ammonia water to 6.8-7.0. Control the dissolved oxygen at 25% by stirring and ventilating, add glucose nutrient solution, and control the residual sugar content in the fermentation broth to not be less than 1g / L;

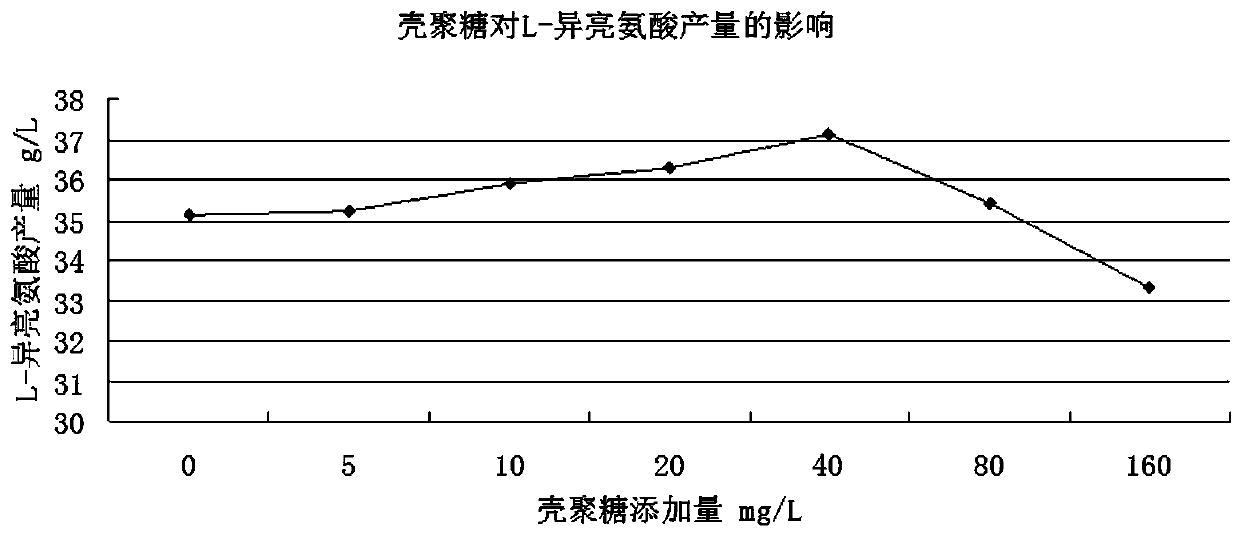

[0035]During the fermentation process, 0.2 L of H 2 o 2 ; In the time of 48h, add chitosan in fermenter, control the concentration of chitosan to be 40mg / L;

[0036] The fermentation medium component is: glucose 80g / L, (NH 4 ) 2 SO 4 20g / L, corn steep liquor 10g / L, KH ...

Embodiment 2

[0042] A kind of production technology of L-isoleucine, it comprises the steps:

[0043] Step 1) Fermentation: Using Corynebacterium glutamicum ATCC14309 as the experimental strain, Corynebacterium glutamicum seed solution (OD 600 The value is 11) According to the inoculum amount of 7%, it is transferred to a 50L fermenter containing 30L fermentation medium for cultivation, the temperature is 30°C, the cultivation time is 60 hours, and the pH of the medium is controlled by automatically adding 20% ammonia water to 6.8-7.0. Control the dissolved oxygen at 20% by stirring and ventilating, add glucose nutrient solution, and control the residual sugar content in the fermentation broth to not be less than 1g / L;

[0044] During the fermentation process, 0.15 L of H 2 o 2 ; In the time of 48h, add chitosan in fermenter, control the concentration of chitosan to be 40mg / L;

[0045] The fermentation medium component is: glucose 80g / L, (NH 4 ) 2 SO 4 20g / L, corn steep liquor 10g...

Embodiment 3

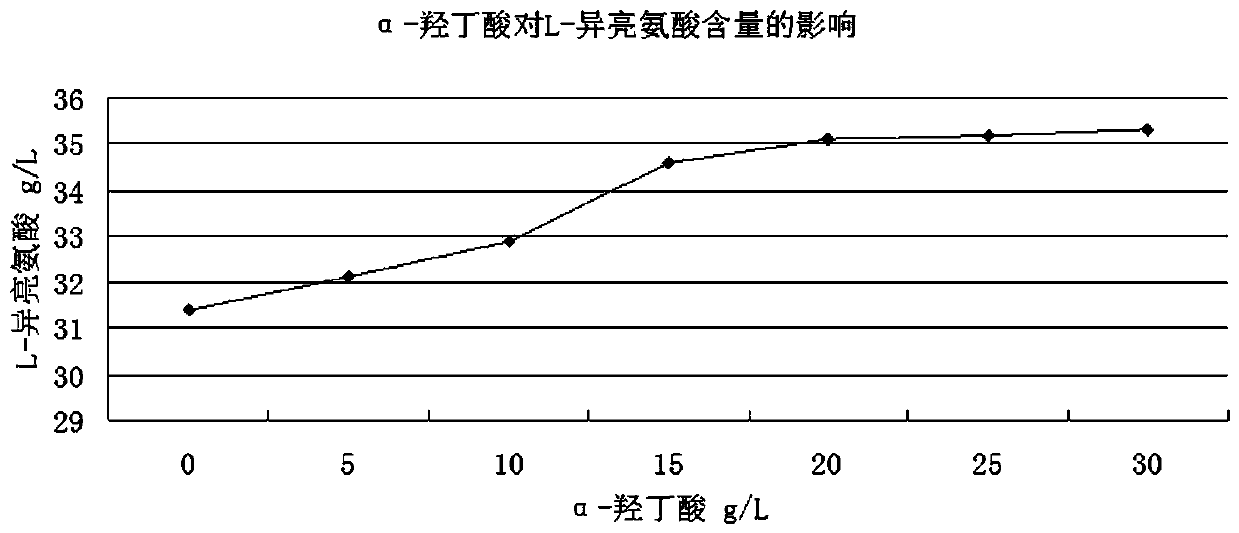

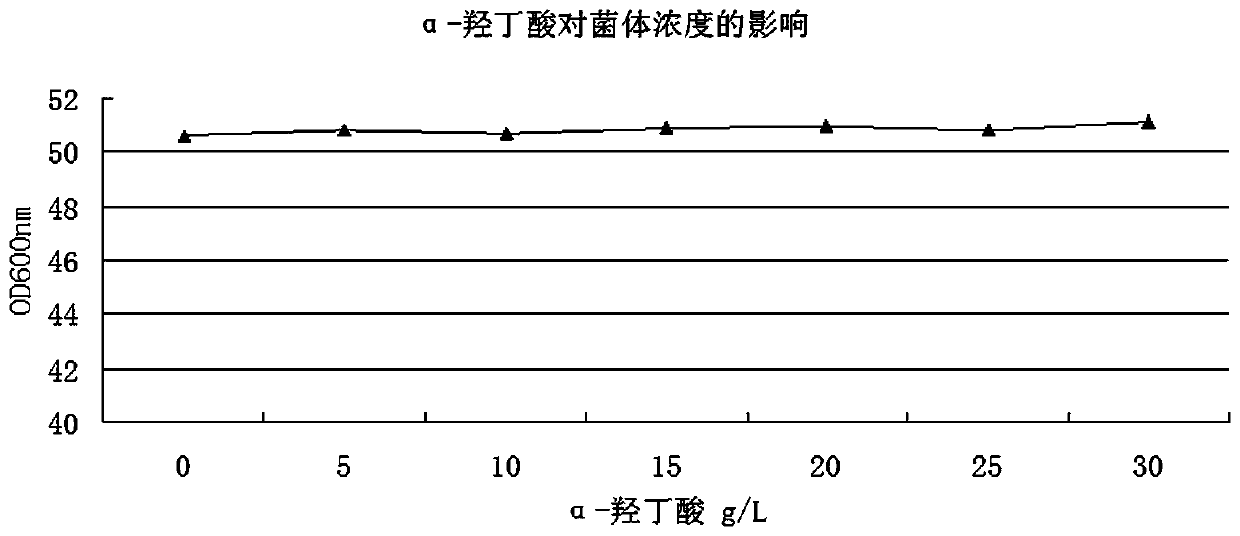

[0065] 1.H 2 o 2 Effects of addition amount and timing on L-isoleucine production and cell biomass in fermentation broth.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com