Work method for mini word paint spraying through gantry type five-axis linkage intelligent vision paint spraying machine

A technology of intelligent vision and five-axis linkage, which is applied to the surface coating liquid device, spraying device, liquid spraying device, etc., can solve the problem of large amount of spraying of advertising three-dimensional characters, difficulty in spraying shading paint on it, high quality requirements, etc. problem, to achieve the effect of rapid action, time saving and uniform spraying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

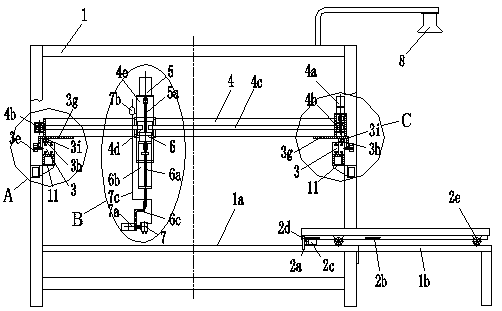

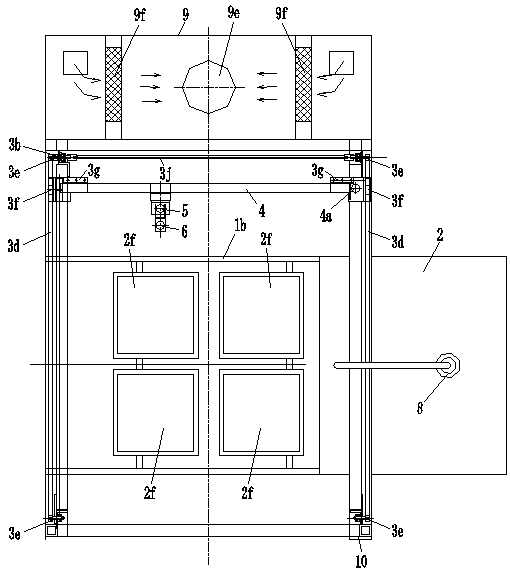

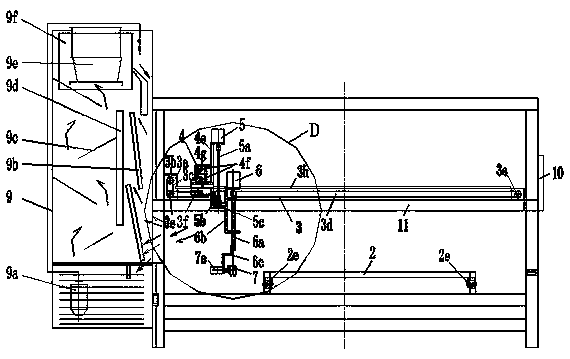

[0024] The structure of the present invention will be further described below with reference to the accompanying drawings.

[0025] figure 1 , 2 , 3 shows a structural diagram of a gantry-type five-axis linkage intelligent visual painting machine. In the figure, this gantry-type five-axis linkage intelligent vision painting machine includes a frame, a longitudinal transmission mechanism, a horizontal transmission mechanism, a vertical transmission mechanism, a nozzle 7, a rotation mechanism of the nozzle 7, a water curtain cabinet 9 and an intelligent vision mechanism. The vertical transmission mechanism is arranged on the frame, the horizontal transmission mechanism is arranged on the longitudinal transmission mechanism, the vertical transmission mechanism is arranged on the horizontal transmission mechanism, and the rotation mechanism of the nozzle 7 is arranged on the vertical transmission mechanism. The outer side of one end of the frame of the paint spraying machine is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com