Method for preparing dimethyl sulfone from dimethyl sulfoxide

A technology of dimethyl sulfoxide and dimethyl sulfone, which is applied in the field of preparation of dimethyl sulfone, can solve problems such as disease occurrence, poor development, and health disorders, and achieve simple production process, high effective utilization rate, and easy The effect of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0009] The invention provides a method for preparing dimethyl sulfone, the method comprising, under oxidation reaction conditions, contacting dimethyl sulfoxide with an oxidizing agent, characterized in that the oxidizing agent is a gas containing ozone.

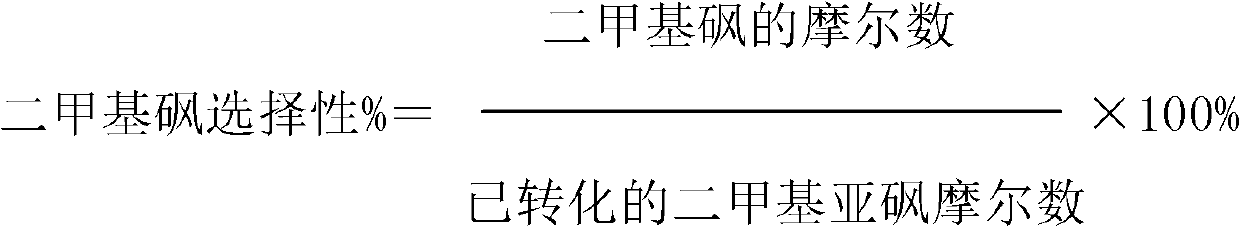

[0010] According to the method of the present invention, an ozone-containing gas is used as an oxidizing agent. Ozone (molecular formula is O 3 , also known as triatomic oxygen, commonly known as "Fu oxygen, super oxygen, active oxygen") is a light blue gas at normal temperature and pressure. The inventors of the present invention found during the research process that using ozone-containing gas as an oxidant to oxidize dimethyl sulfoxide has high selectivity to dimethyl sulfone, and the process is simple and easy, and the operating conditions are mild. Moreover, ozone can be decomposed into oxygen by itself at room temperature, and there will be no disadvantages such as the need to process a solution containing hydrogen pe...

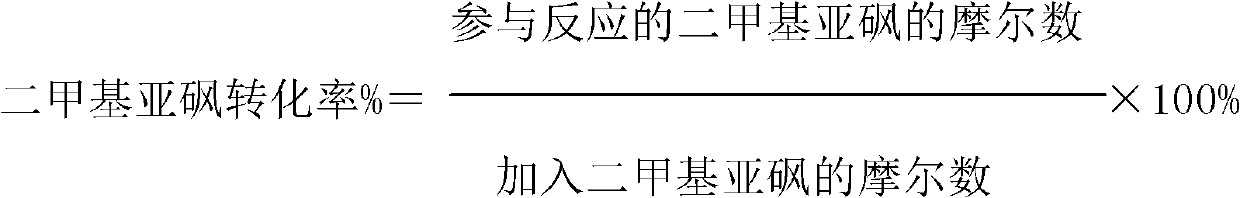

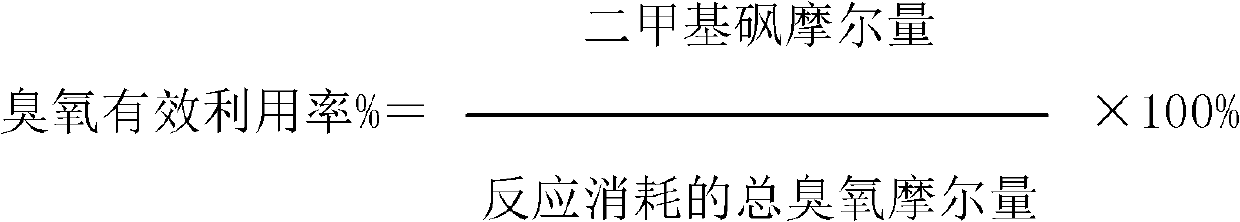

Embodiment 1

[0037] At a temperature of 60°C and a pressure of 0.5 MPa, with ozone (15% by volume, the rest being oxygen) as an oxidant, dimethyl sulfoxide, ozone and solvent acetone are reacted in a molar ratio of 1:1:1 . The results of the reaction for 2 hours are as follows: the conversion rate of dimethyl sulfoxide is 74%; the effective utilization rate of ozone is 76%; the selectivity of dimethyl sulfone is 99%.

Embodiment 2

[0039] At a temperature of 20°C and a pressure of 1.5 MPa, with ozone (30% by volume, the rest being air) as an oxidant, dimethyl sulfoxide, ozone and solvent acetic acid are reacted in a molar ratio of 1:1:5 . The results of the reaction for 5 hours are as follows: the conversion rate of dimethyl sulfoxide is 53%; the effective utilization rate of ozone is 81%; the selectivity of dimethyl sulfone is 97%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radial length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com