Surface modified microballons of containing phosphazene, and preparation method

A surface modification and microsphere technology, which is applied in chemical instruments and methods, catalyst carriers, physical/chemical process catalysts, etc., to achieve the effects of simple operation, environmental friendliness, and good biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] In a 500 ml flask, 1.08 g (4.32 mmol) of 4,4'-dihydroxydiphenylsulfone was dissolved in 250 ml of acetone, wherein the concentration of 4,4'-dihydroxydiphenylsulfone was 0.0043 g / ml; Add 0.87 g (8.64 mmol) of acid-binding agent triethylamine to the above reaction system; under the condition of 25° C., under the action of 100 W ultrasound, slowly add 30 ml of hexachlorocyclotriphosphazene with a concentration of 0.1 g / ml The acetone solution was added dropwise to the above system and reacted for 2 hours. After the reaction, the crude product was obtained by centrifugal separation, washed three times with acetone and then three times with deionized water, and then dried in a vacuum oven for 24 hours to obtain 0.64 g of surface-modified microspheres containing phosphazene.

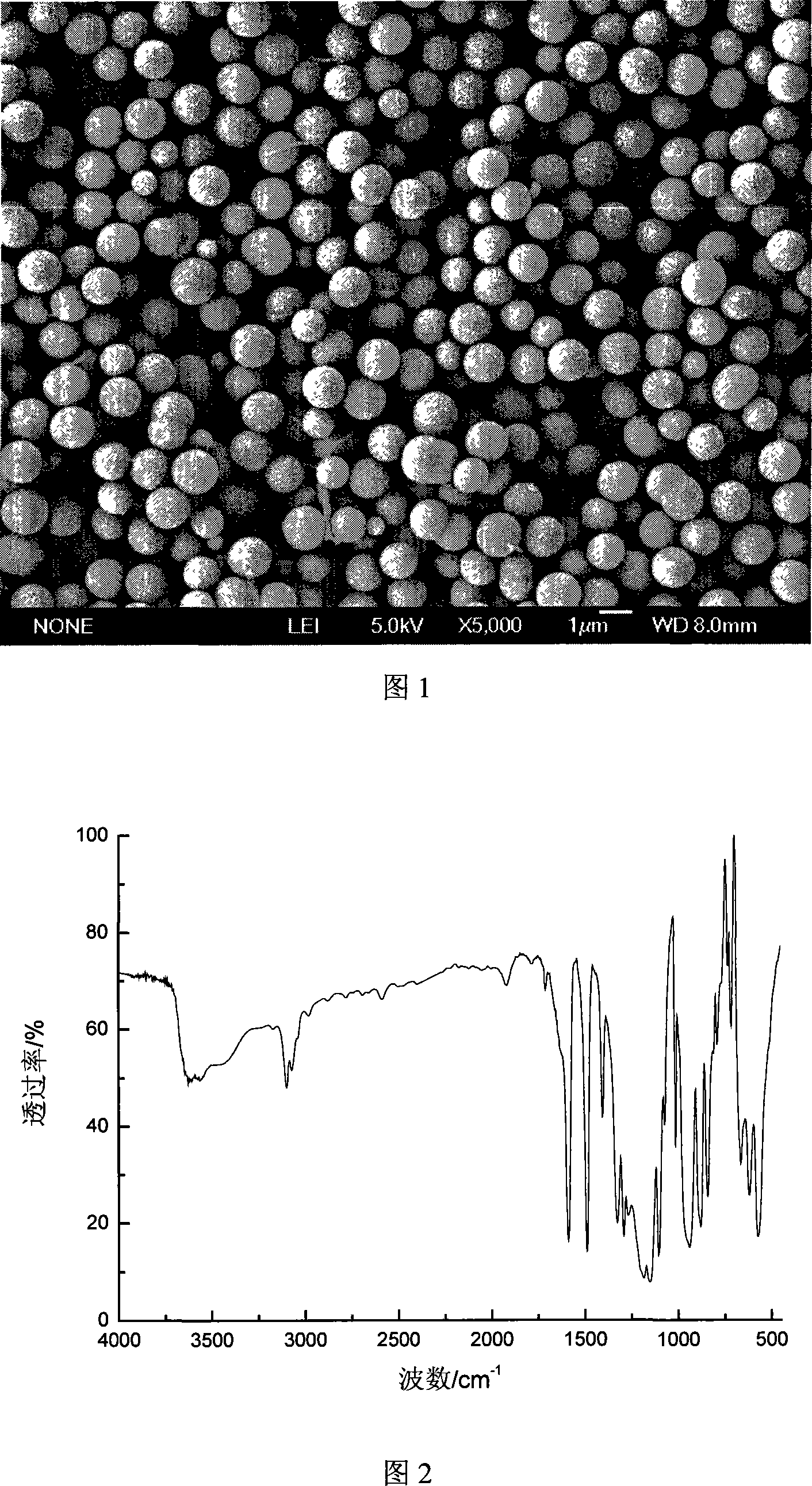

[0020] Fig. 1 is the field emission scanning electron microscope photo of the phosphazene-containing surface-modified microspheres obtained in Example 1. It can be seen from the photo that the diameter...

Embodiment 2

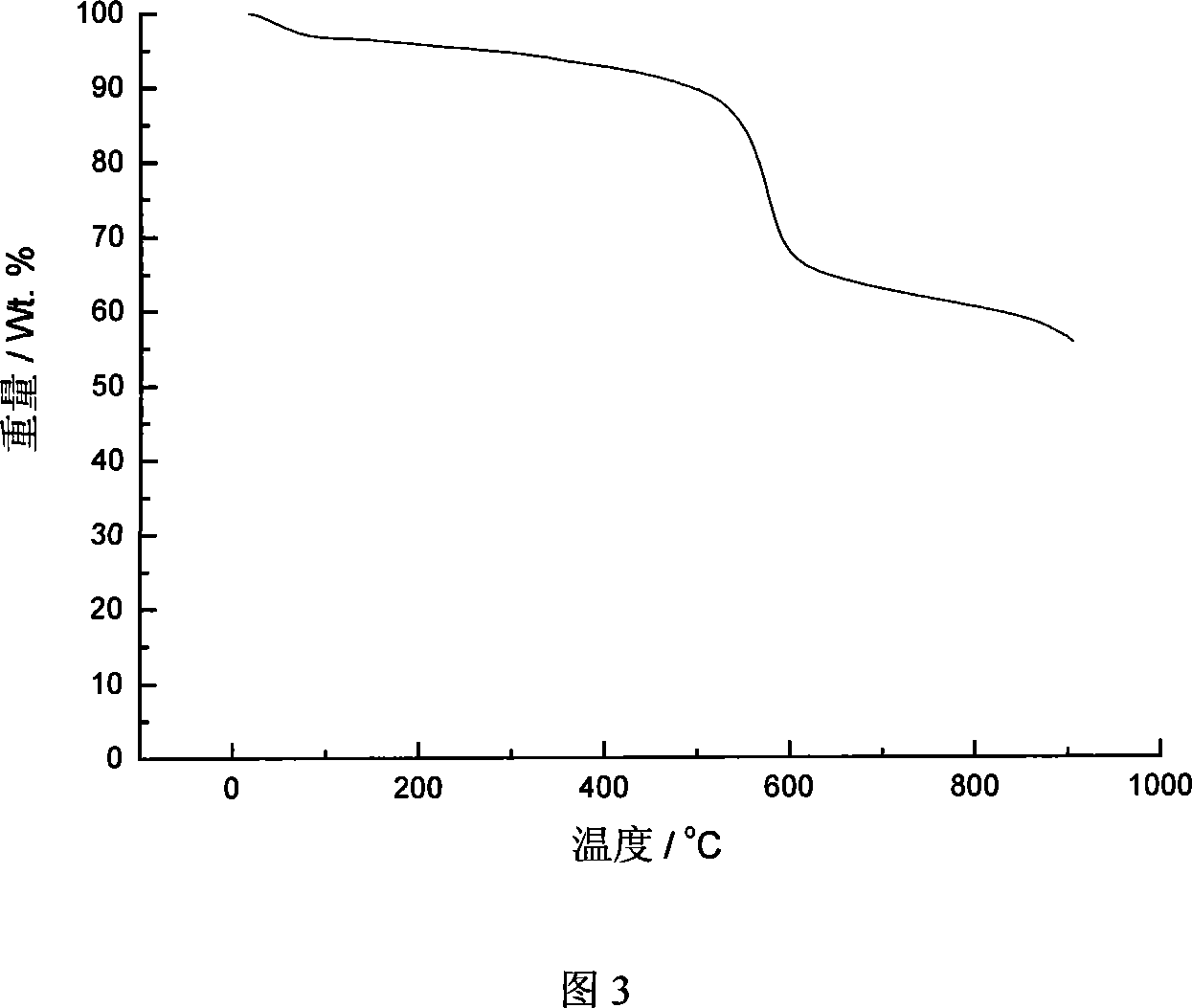

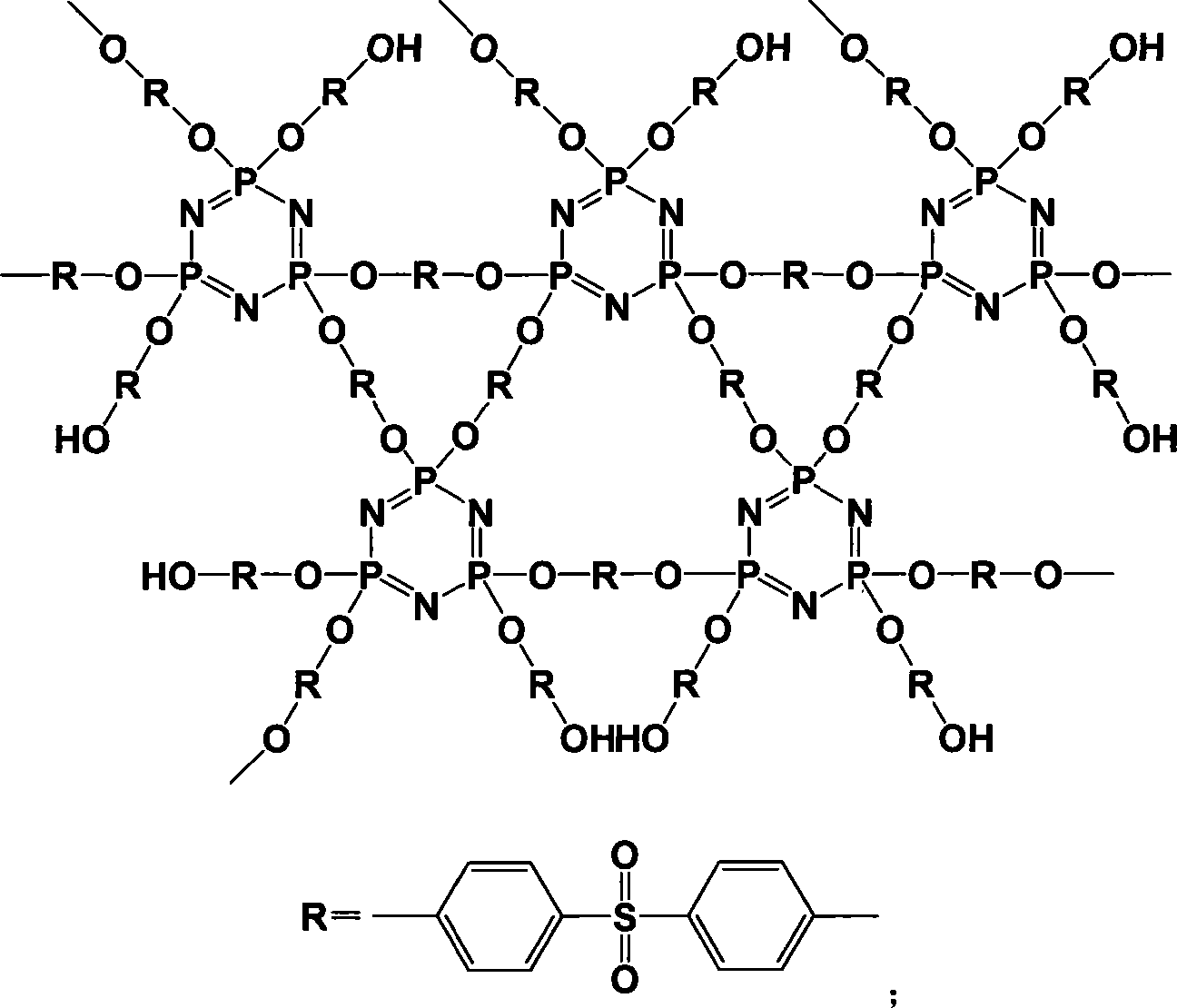

[0024] In a 500 ml flask, 1.08 g (4.32 mmol) of 4,4'-dihydroxydiphenylsulfone was dissolved in 250 ml of acetone, wherein the concentration of 4,4'-dihydroxydiphenylsulfone was 0.0043 g / ml; Add 0.87 g (8.64 mmol) of acid-binding agent triethylamine to the above-mentioned reaction system; under the condition of 25°C, under the action of magnetic stirring, slowly add 30 ml of hexachlorocyclotriphosphazene with a concentration of 0.1 g / ml The acetone solution was added dropwise to the above system and reacted for 2 hours. After the reaction, the crude product was obtained by centrifugal separation, washed three times with acetone and then three times with deionized water, and then dried in a vacuum oven for 24 hours to obtain 0.56 g of surface-modified microspheres containing phosphazene. The diameter of the microsphere is 1.0-1.2 microns, and the specific surface area is 11.7 meters 2 / gram. Spectrum analysis shows that its structure is the cross-linked condensation structure ...

Embodiment 3

[0026] Using the equipment and preparation process described in Example 2, except that mechanical stirring was used for external field action, 0.61 g of hydroxyl-modified microspheres was obtained. The diameter of the microsphere is 1.1-1.5 microns, and the specific surface area is 10.4 meters 2 / gram. Spectrum analysis shows that its structure is the cross-linked condensation structure of hexachlorocyclotriphosphazene and 4,4'-dihydroxydiphenyl sulfone.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com