Preparation method of high-purity polyether-ether-ketone resin

A polyether ether ketone resin, high-purity technology, applied in the field of preparation of high-purity polyether ether ketone resin, can solve the problems of reduced molecular collision probability, high impurity content in products, and difficulty in crushing and sieving, so as to achieve easy control of the production process, The effect of improving product quality and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

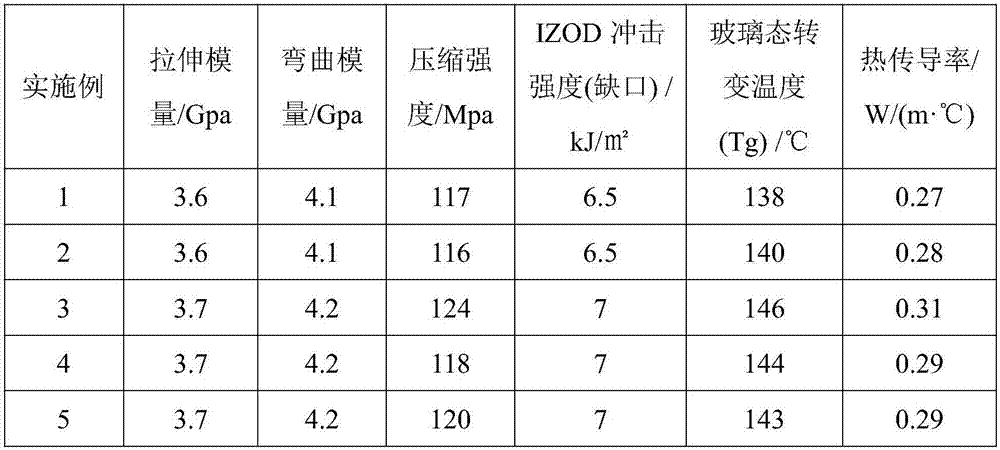

Examples

Embodiment 1

[0013] First vacuumize the reactor equipped with a mechanical stirrer, reflux condenser and thermometer, and then introduce high-purity nitrogen (purity ≥ 99.9995%). After repeating three times, the oxygen in the system is completely replaced by nitrogen, and the temperature is maintained at 2m 3 / h nitrogen flow to prevent air from entering, add 654g diphenyl sulfone, heat until it is completely dissolved, add 218g 4,4'-difluorobenzophenone, stir to dissolve, add 110g hydroquinone, stir to make it Dissolved, Na in advance 2 CO 3 and K 2 CO 3 The powder is dried, crushed and sieved, and accurately weighed 105g Na 2 CO 3 and 1.4g K 2 CO 3 , immediately added to the reaction system, stirred at 170°C for 30 minutes to form a salt with hydroquinone and dissolved, and quickly raised the temperature of the system to 190°C, after 1 hour of reaction, the temperature of the system was raised within 15 minutes At the same time, increase the stirring speed, stop heating after 5 ho...

Embodiment 2

[0015] First vacuumize the reactor equipped with a mechanical stirrer, reflux condenser and thermometer, and then introduce high-purity nitrogen (purity ≥ 99.9995%). After repeating three times, the oxygen in the system is completely replaced by nitrogen, and the temperature is maintained at 2m 3 / h nitrogen flow to prevent oxygen from entering, add 654g diphenyl sulfone, heat until it dissolves, add 218g 4,4'-difluorobenzophenone, stir to dissolve, add 110g hydroquinone, stir to dissolve , Na in advance 2 CO 3 and K 2 CO 3 Powder drying, crushing and sieving, accurate weighing of 96gNa 2 CO 3 and 12.5g K 2 CO 3 , immediately added to the reaction system, stirred at 170°C for 30 minutes to form a salt with hydroquinone and dissolved, and quickly raised the temperature of the system to 190°C, after 1 hour of reaction, the temperature of the system was raised within 15 minutes At the same time, increase the stirring speed, stop heating after 5 hours of reaction, and immed...

Embodiment 3

[0017] First vacuumize the reactor equipped with a mechanical stirrer, reflux condenser and thermometer, and then introduce high-purity nitrogen (purity ≥ 99.9995%). After repeating three times, the oxygen in the system is completely replaced by nitrogen, and the temperature is maintained at 2m 3 / h nitrogen flow to prevent oxygen from entering, add 654g diphenyl sulfone, heat until it dissolves, add 218g 4,4'-difluorobenzophenone, stir to dissolve, add 110g hydroquinone, stir to dissolve , Na in advance 2 CO 3 and K 2 CO 3 The powder is dried, crushed and sieved, and accurately weighed 100g Na 2 CO 3 and 5g K 2 CO 3 , immediately added to the reaction system, stirred at 170°C for 30 minutes to form a salt with hydroquinone and dissolved, and quickly raised the temperature of the system to 190°C, after 1 hour of reaction, the temperature of the system was raised within 15 minutes Increase the stirring speed to 315°C at the same time, stop heating after 5 hours of reactio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com