Nitrogen-phosphorus-sulfur co-doped porous carbon loaded metal phosphide nano composite material as well as preparation method and application thereof

A nano-composite material and metal phosphide technology, applied in the field of water pollution treatment, can solve the problems of poor chemical stability, easy loss of metal ions, low catalytic activity, etc. The effect of improving catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

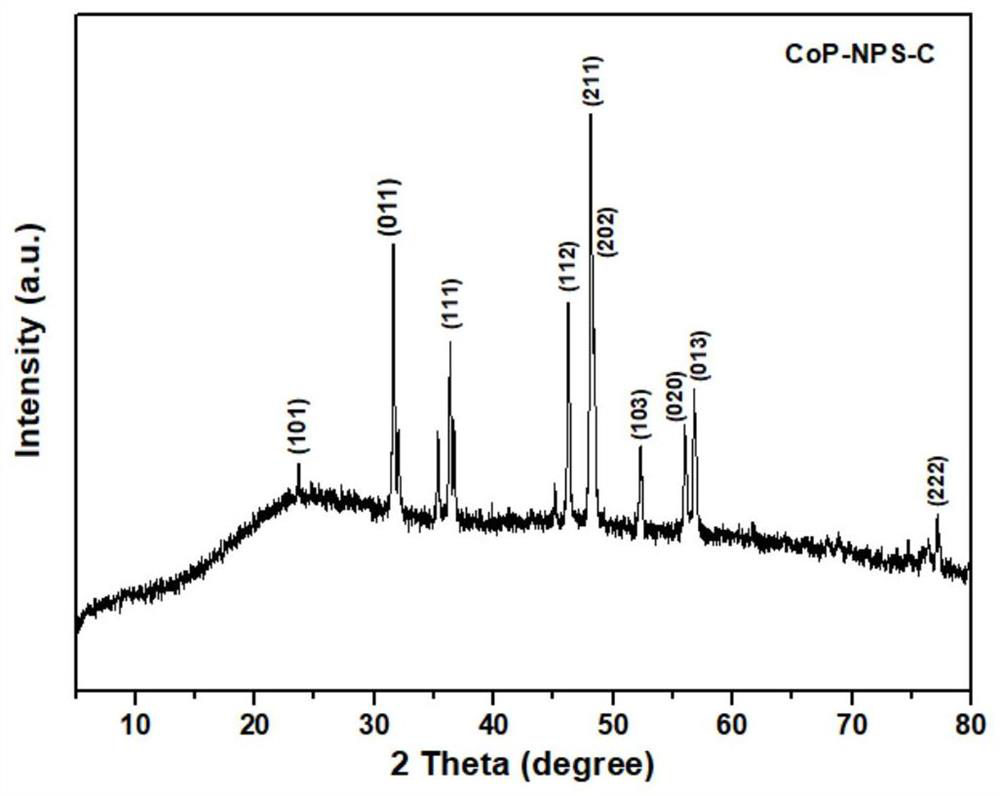

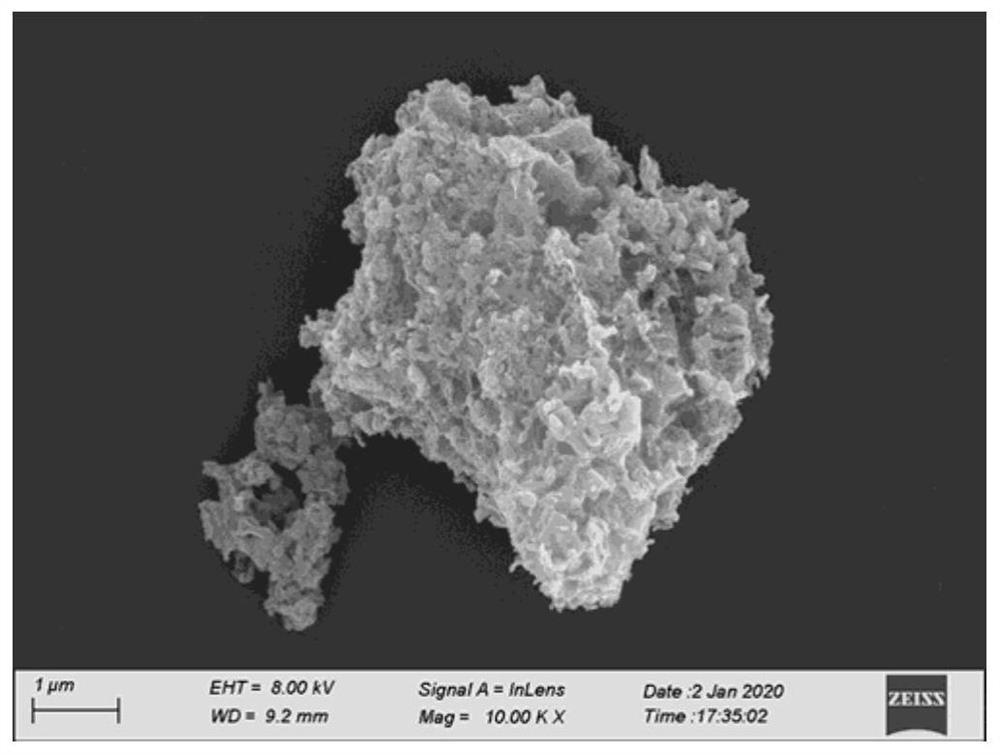

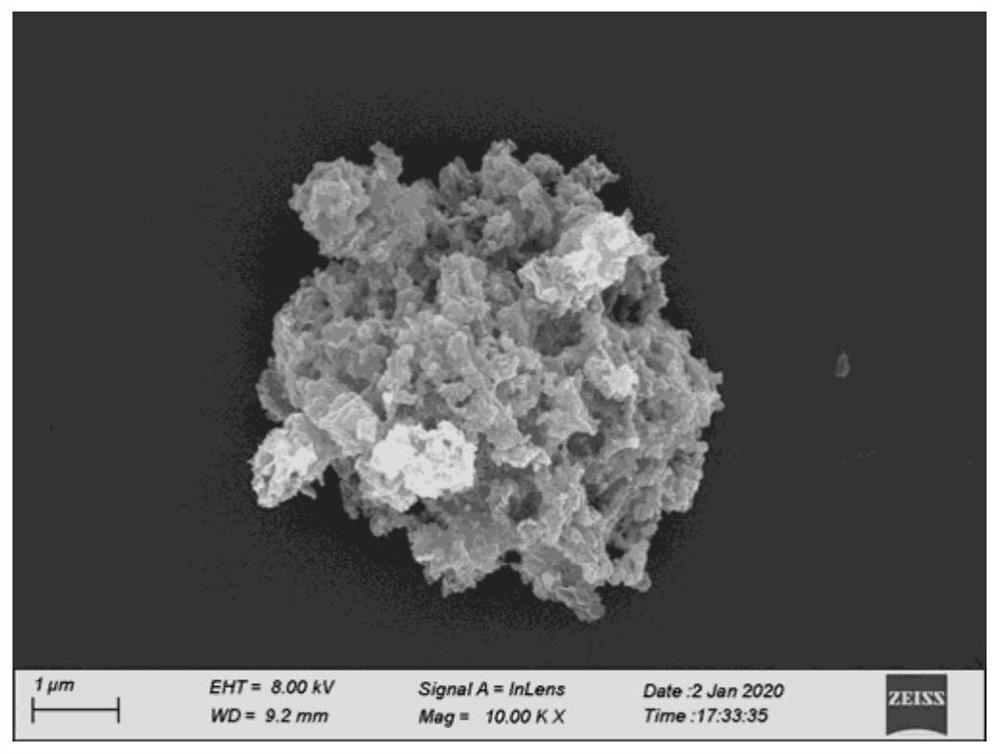

[0072] Example 1, Preparation of cobalt phosphide nanocomposite material supported by nitrogen, phosphorus and sulfur co-doped porous carbon

[0073] Concrete preparation process is as follows:

[0074]0.0747g (0.3mmol) of cobalt acetate [Co(CH 3 COO) 2 4H 2 O], 3g of dicyandiamide, and 15g of ammonium chloride were heated and refluxed in 30mL of deionized water at 80°C for 4 hours to obtain a completely dissolved mixed solution, then heated to 100°C to evaporate the deionized water, and completely dried in an oven at 100°C Finally, a uniformly mixed powder of the three was obtained; the mixed powder was raised from room temperature to 550°C at a heating rate of 2°C / min in a tube furnace, pyrolyzed at 550°C for 2 hours, and N was introduced into the tube furnace 2 , the flow rate is controlled at 20-30mL / min, and Co-g-C can be obtained after natural cooling 3 N 4 Material;

[0075] 200mg Co-g-C 3 N 4 Sonicate the material in 50mL of methanol for 30min to obtain a well-...

Embodiment 2

[0079] Example 2, Preparation of nitrogen, phosphorus, and sulfur co-doped porous carbon-supported titanium phosphide nanocomposites

[0080] Concrete preparation process is as follows:

[0081] 24g (100mmol) of titanium sulfate [Ti(SO 4 ) 2 ], 800g urea, and 2kg ammonium carbonate were ground and mixed to obtain a uniformly mixed powder; the mixed powder was raised from room temperature to 580°C at a heating rate of 5°C / min in a tube furnace, and pyrolyzed at 580°C 4h, He was introduced into the tube furnace, the flow rate was controlled at about 50mL / min, and Ti-g-C was obtained after natural cooling. 3 N 4 Material;

[0082] 80g Ti-g-C 3 N 4 The material was sonicated in 4L of ethanol for 45min to obtain a well-dispersed suspension A; 1L of ethanol solution dissolved with 80g HCCP and 200g BPS was added dropwise to the suspension A; after mixing for 40min, continue to slowly add 400mL of dimethylformamide Amine, separation operation after continuous reaction for 30h....

Embodiment 3

[0086] Example 3, Preparation of manganese phosphide nanocomposite material supported by nitrogen, phosphorus and sulfur co-doped porous carbon

[0087] Concrete preparation process is as follows:

[0088] 12.25g (50mmol) manganese acetate [Mn(CH 3 COO) 2 4H 2 O], 100g melamine, and 100g ammonium sulfate were heated and refluxed at 60°C in 1L of deionized water for 12h to obtain a completely dissolved mixed solution, then heated to 90°C to evaporate the deionized water, dried completely in an oven at 100°C, and ground to obtain The three are uniformly mixed powder; the mixed powder is raised from room temperature to 650°C at a heating rate of 20°C / min in a tube furnace, and pyrolyzed at 650°C for 2h, N 2 is passed into the tube furnace, and the flow rate is Controlled at 30-40mL / min, the Mn-g-C 3 N 4 Material;

[0089] 5g Mn-g-C 3 N 4 The material was sonicated in 1L of acetonitrile for 60min to obtain a well-dispersed suspension A; 200mL of acetonitrile solution disso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com