Halogen-free flame-retardant epoxy resin composition and application thereof

A technology of epoxy resin and epoxy resin solution, which is applied in the direction of layered products, metal layered products, circuit substrate materials, etc., and can solve the problems of hard and brittle halogen-free phosphorus-containing flame-retardant resins, insufficient heat resistance, and high water absorption and other problems, to achieve the effect of good flame retardancy, low water absorption and excellent flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

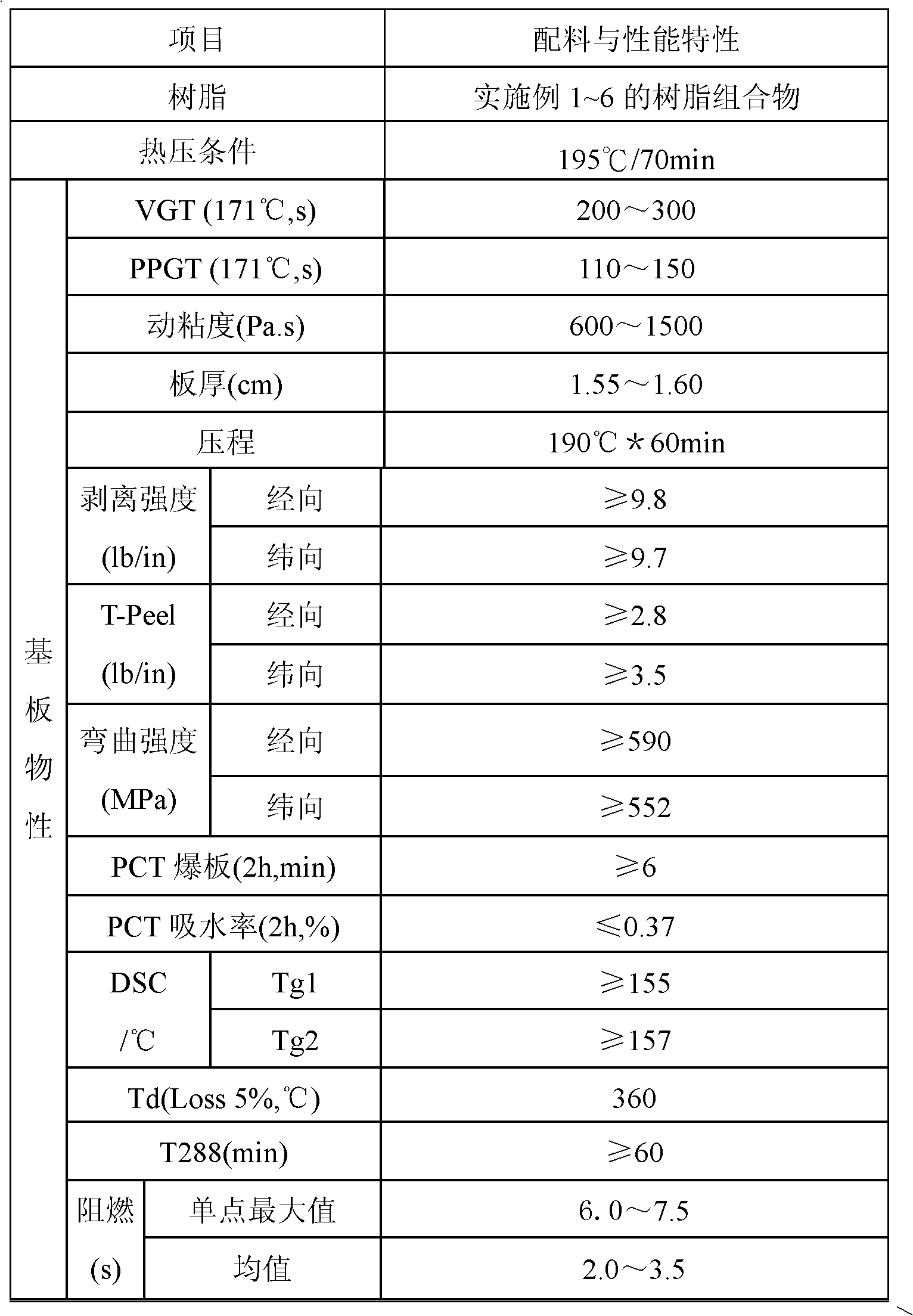

Examples

Embodiment 1

[0024] (1) Preparation of phosphorus-containing epoxy resin butanone solution:

[0025] Add 27 parts by weight of novolac epoxy resin and 12 parts by weight of reactive phosphorus-containing compound into the reaction tank, add 0.012 parts by weight of catalyst triphenylphosphine at 120 ° C, react at 175 ° C for 2.5 hours, and then mix in 7 parts by weight of low molecular weight Bisphenol A type epoxy resin, 7 parts by weight of high molecular weight bisphenol A type epoxy resin and 3.7 parts by weight of tetraphenol ethane tetraglycidyl ether are dissolved with methyl ethyl ketone to form a solution with a solid content of 75%. The above-mentioned consumptions are all parts by weight.

[0026] (2) Preparation of halogen-free flame retardant epoxy resin composition:

[0027] Weigh the phosphorus-containing epoxy resin methyl ethyl ketone solution obtained in step (1) and curing agents such as benzoxazine and diaminodiphenyl sulfone, add inorganic fillers and curing accelerat...

Embodiment 2

[0036] (1) Preparation of phosphorus-containing epoxy resin butanone solution:

[0037] Add 27 parts by weight of novolac epoxy resin and 12 parts by weight of reactive phosphorus-containing compound into the reaction tank, add 0.012 parts by weight of catalyst triphenylphosphine at 120 ° C, react at 175 ° C for 2.5 hours, and then mix in 7 parts by weight of low molecular weight Bisphenol A type epoxy resin, 7 parts by weight of high molecular weight bisphenol A type epoxy resin and 3.7 parts by weight of tetraphenol ethane tetraglycidyl ether are dissolved with methyl ethyl ketone to form a solution with a solid content of 75%. The above-mentioned consumptions are all parts by weight.

[0038] (2) Preparation of halogen-free flame retardant epoxy resin composition:

[0039] Weigh the phosphorus-containing epoxy resin methyl ethyl ketone solution obtained in step (1) and curing agents such as benzoxazine and diaminodiphenyl sulfone, add inorganic fillers and curing accelerat...

Embodiment 3

[0048] (1) Preparation of phosphorus-containing epoxy resin butanone solution:

[0049]Add 27 parts by weight of novolac epoxy resin and 12 parts by weight of reactive phosphorus-containing compound into the reaction tank, add 0.012 parts by weight of catalyst triphenylphosphine at 120 ° C, react at 175 ° C for 2.5 hours, and then mix in 7 parts by weight of low molecular weight Bisphenol A type epoxy resin, 7 parts by weight of high molecular weight bisphenol A type epoxy resin and 3.7 parts by weight of tetraphenol ethane tetraglycidyl ether are dissolved with methyl ethyl ketone to form a solution with a solid content of 75%. The above-mentioned consumptions are all parts by weight.

[0050] (2) Preparation of halogen-free flame retardant epoxy resin composition:

[0051] Weigh the phosphorus-containing epoxy resin methyl ethyl ketone solution obtained in step (1) and curing agents such as benzoxazine and diaminodiphenyl sulfone, add inorganic fillers and curing accelerato...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com