Method for preparing graphene aerogel and application thereof

A graphene aerogel, graphene hydrogel technology, applied in graphene, chemical instruments and methods, inorganic chemistry and other directions, can solve the problems of improving the difficulty of graphene aerogel production, high production cost, and high technical requirements , to achieve the effect of improving electrical conductivity and mechanical properties, easy control, and wide source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

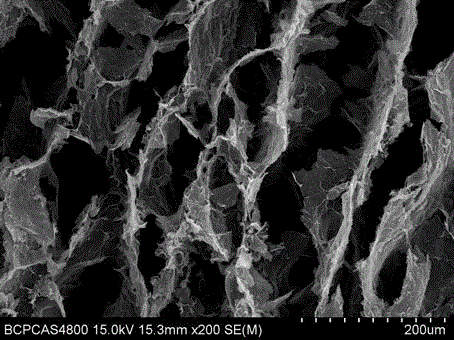

Image

Examples

Embodiment 1

[0037] A kind of preparation method of graphene airgel, concrete steps are:

[0038] The first step: preparation of graphene oxide dispersion: using the method of exfoliating graphite oxide, specifically: first mix 5g of natural flake graphite, 3g of sodium nitrate and 120mL of concentrated sulfuric acid at 5°C, slowly add 15g of potassium permanganate , stirred at 35°C for 6h, diluted with 500mL deionized water, added 15mL of 30% hydrogen peroxide, ultrasonicated for 0.5h, poured off the supernatant after standing for 1 day, dialyzed for 7 days, centrifuged at 2000rpm to take the supernatant to obtain a uniformly dispersed graphene oxide dispersion liquid;

[0039] The second step is to prepare the graphene oxide mixed solution: uniformly disperse diaminodiphenylmethane in the graphene oxide dispersion to obtain the graphene oxide mixed solution, wherein the mass ratio of graphene oxide to diaminodiphenylmethane is 1:10, the graphene oxide concentration in the resulting mixe...

Embodiment 2

[0045] A kind of preparation method of graphene airgel, concrete steps are:

[0046] First, prepare the graphene oxide dispersion: using the exfoliated graphite oxide method, first mix 5g of natural flake graphite, 3g of sodium nitrate and 120mL of concentrated sulfuric acid at 4°C, add 15g of potassium permanganate, add slowly, and stir at 40°C for 6h After diluting with 500mL deionized water, add 15mL of 30% hydrogen peroxide, sonicate for 0.5h, pour off the supernatant after standing for 1 day, dialyze for 9 days, centrifuge at 3000rpm to take the upper liquid to obtain a uniformly dispersed graphene oxide dispersion;

[0047] Second, configure the graphene oxide mixed solution: uniformly disperse diaminodiphenylmethane into the graphene oxide dispersion, wherein the mass ratio of graphene oxide to diaminodiphenylmethane is 1:40, and in the resulting mixed solution Graphene oxide concentration is 4mg / mL;

[0048] Third, inject the graphene oxide mixture into the sample bot...

Embodiment 3

[0053] A kind of preparation method of graphene airgel, concrete steps are:

[0054] First, prepare the graphene oxide dispersion: using the exfoliated graphite oxide method, first mix 5g of natural flake graphite, 3g of sodium nitrate and 120mL of concentrated sulfuric acid at 3°C, add 15g of potassium permanganate, add slowly, and stir at 35°C for 6h After diluting with 500mL deionized water, add 15mL of 30% hydrogen peroxide, sonicate for 0.5h, pour off the supernatant after standing for 1 day, dialyze for 10 days, centrifuge at 4000rpm to take the supernatant to obtain a uniformly dispersed graphene oxide dispersion;

[0055] Second, configure the graphene oxide mixed solution: uniformly disperse diaminodiphenylmethane into the graphene oxide dispersion, wherein the mass ratio of graphene oxide to diaminodiphenylmethane is 1:60, and in the resulting mixed solution Graphene oxide concentration is 6mg / mL;

[0056] Third, inject the graphene oxide mixture into the sample bot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com