High-transparency low-temperature-impact-resistant flame-retardant polycarbonate composite material and preparation method thereof

A technology of flame-retardant polycarbonate and composite materials, which is applied in the field of high-transparency, low-temperature impact-resistant, flame-retardant polycarbonate composite materials and its preparation, and can solve the impact of not mentioning low-temperature impact resistance of resins, market expansion restrictions, and prices. Expensive and other problems, to achieve the effect of short processing and molding cycle, excellent flame retardant performance, and low processing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

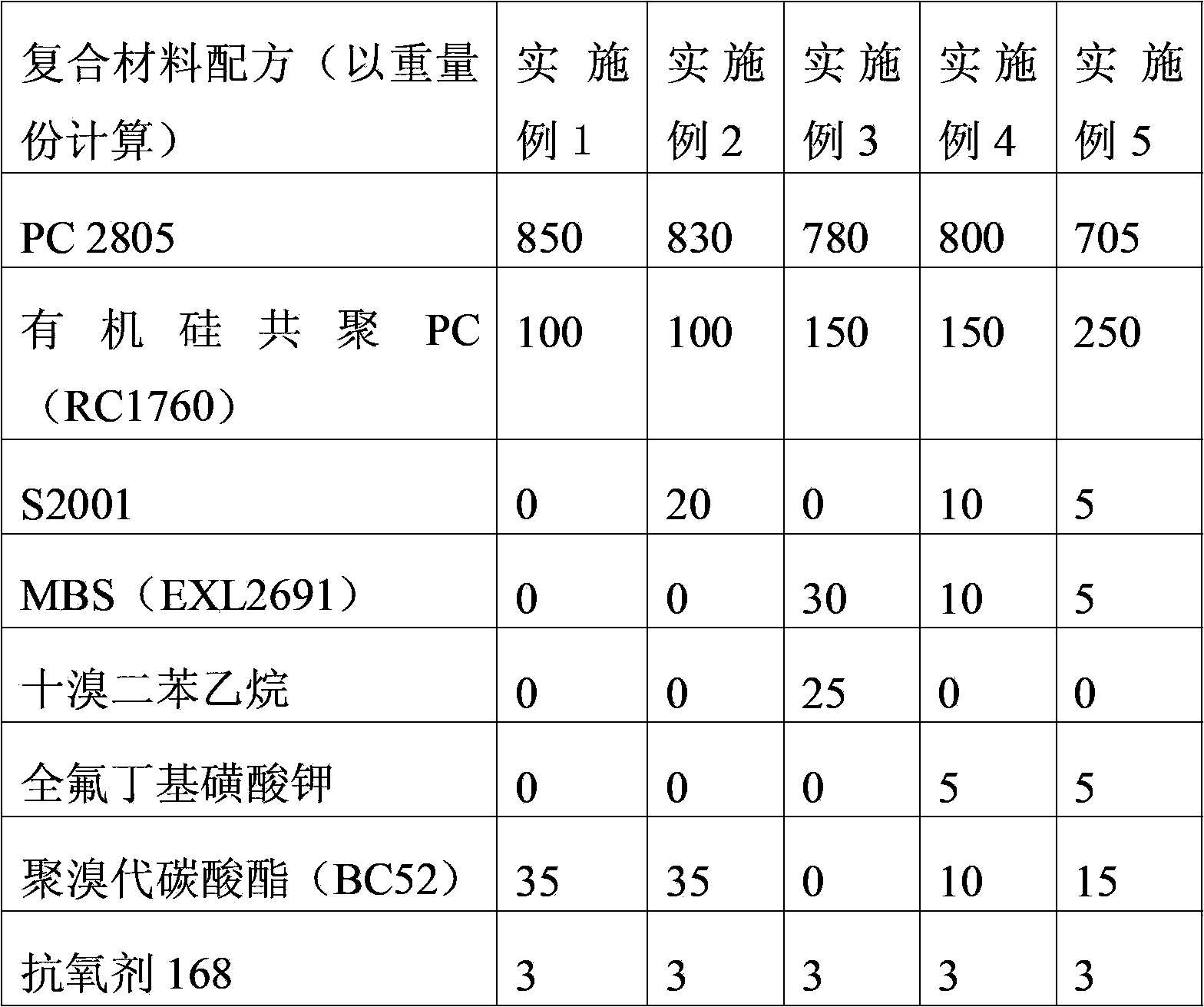

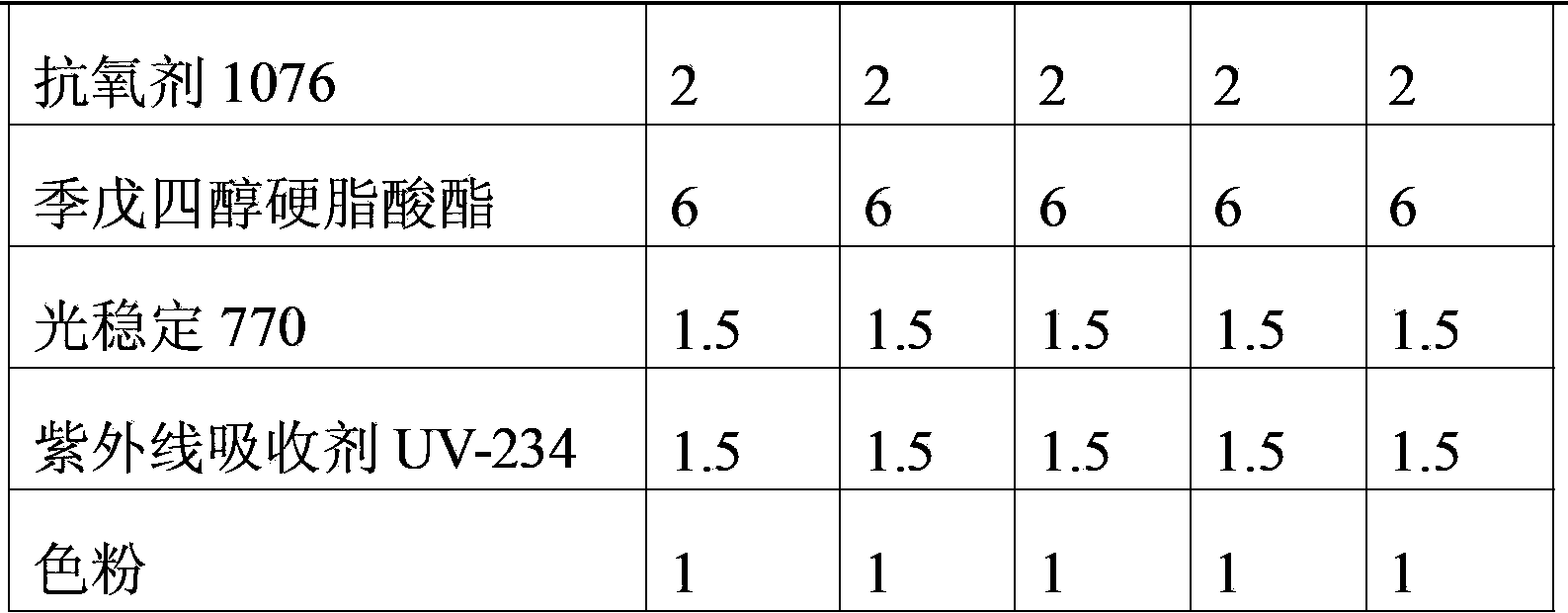

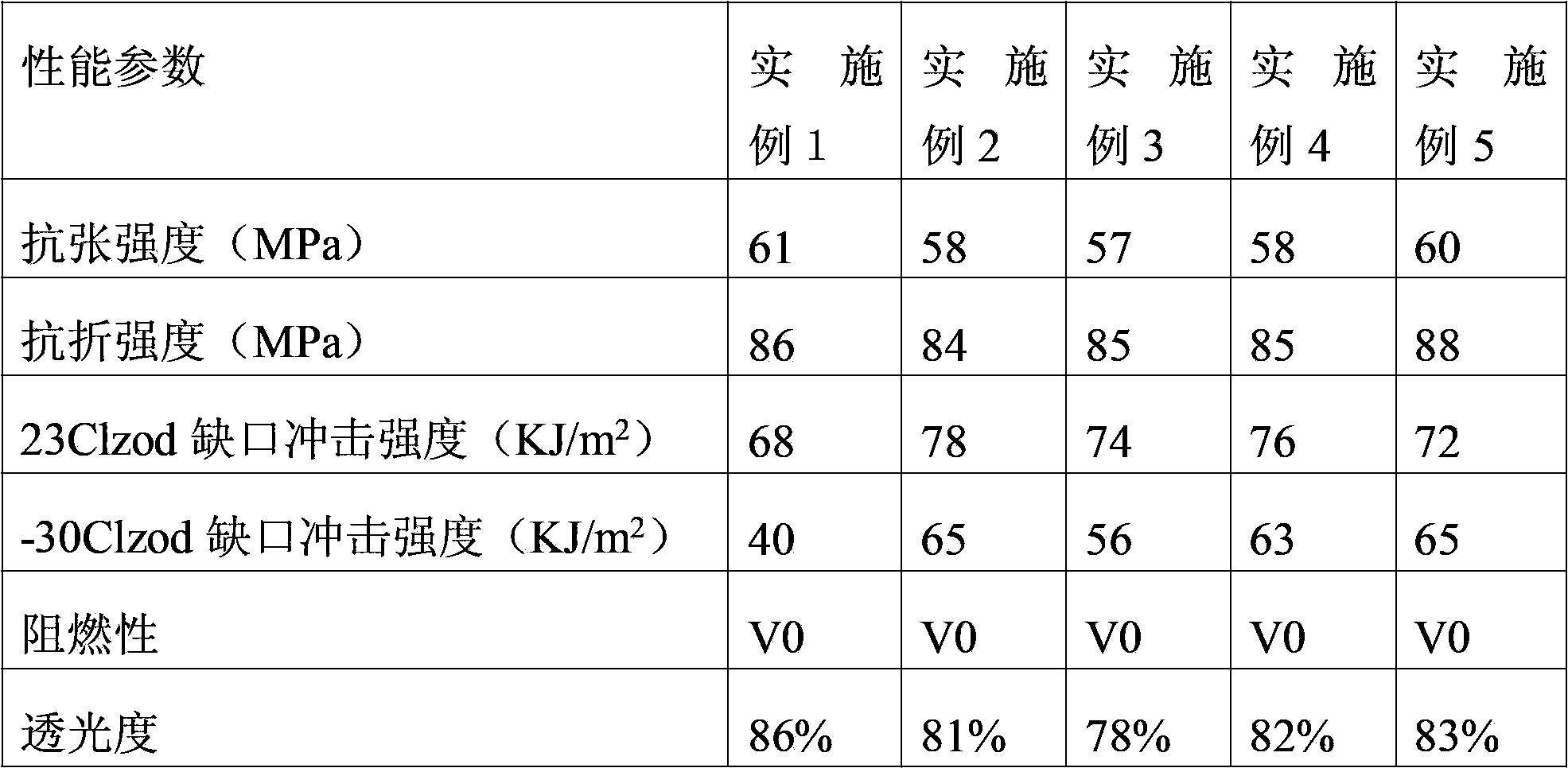

Embodiment 1

[0038] The following components in parts by weight (1 part = 100g): 850 parts of PC type 2805, 100 parts of silicone copolymerized PC, 35 parts of polybromocarbonate, 3 parts of antioxidant 168, 2 parts of antioxidant Agent 1076, 6 parts of pentaerythritol stearate, 1.5 parts of light stabilizer 770, 1.5 parts of ultraviolet absorber UV-234 and 1 part of toner are mixed in a high mixer for 2 to 3 minutes, and then twin-screw at 260 to 280 ° C Extrusion and granulation, the resulting pellets are dried at 120°C for 4 hours and then injection molded into standard strips at 260-280°C.

Embodiment 2

[0040] The following components in parts by weight (1 part = 100g): 830 parts of PC of model 2805, 100 parts of silicone copolymerized PC, 20 parts of silicone toughening agent of model S2001, 35 parts of polybromocarbonic acid Ester, 3 parts of antioxidant 168, 2 parts of antioxidant 1076, 6 parts of pentaerythritol stearate, 1.5 parts of light stabilized 770, 1.5 parts of ultraviolet absorber UV-234 and 1 part of toner are mixed in a high mixer for 2 ~3 minutes, then twin-screw extrusion pelletization at 255~275°C, the obtained pellets are dried at 120°C for 4 hours, and then injection molded into standard strips at 255~275°C.

Embodiment 3

[0042] The following components in parts by weight (1 part = 100g): 780 parts of PC type 2805, 150 parts of silicone copolymerized PC, 30 parts of MBS, 25 parts of decabromodiphenylethane, 3 parts of antioxidant 168 , 2 parts of antioxidant 1076, 6 parts of pentaerythritol stearate, 1.5 parts of light stabilized 770, 1.5 parts of ultraviolet absorber UV-234 and 1 part of toner are mixed in a high mixer for 2 to 3 minutes, and then mixed at 255 to Twin-screw extrusion granulation at 275°C, the resulting pellets were dried at 120°C for 4 hours and then injection molded into standard strips at 255-275°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com