Combined ultrathin double-side copper foil substrate and making method thereof

A technology of double-sided copper foil and manufacturing method, applied in chemical instruments and methods, lamination, layered products, etc., can solve the problems of high cost, high production cost, thick size, etc., and achieve simple manufacturing method, high dimensional stability, etc. the effect of high flexibility and high buckling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

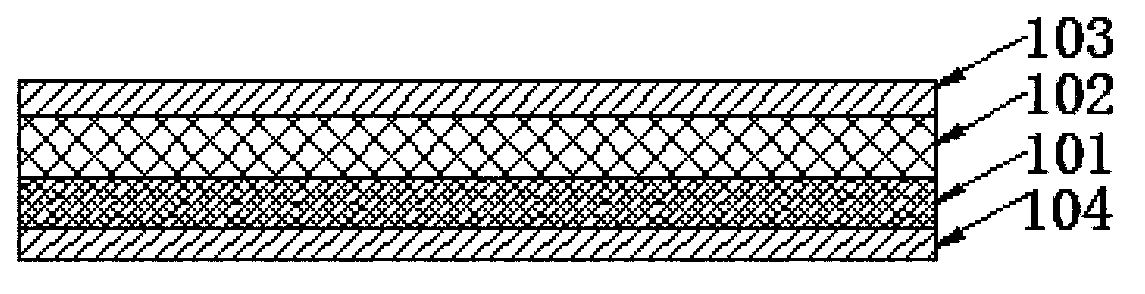

[0025] Embodiment: a composite ultra-thin double-sided copper foil substrate, such as figure 1 As shown, it is composed of a first copper foil layer 103, a polyimide layer 102, an adhesive layer 101 and a second copper foil layer 104. The polyimide layer 102 is sandwiched between the adhesive layer 101 and the second copper foil layer. Between a copper foil layer 103, the adhesive layer 101 is sandwiched between the second copper foil layer 104 and the polyimide layer 102, wherein the polyimide layer 102 and the adhesive The sum of the thicknesses of both layers 101 is 8-25 microns.

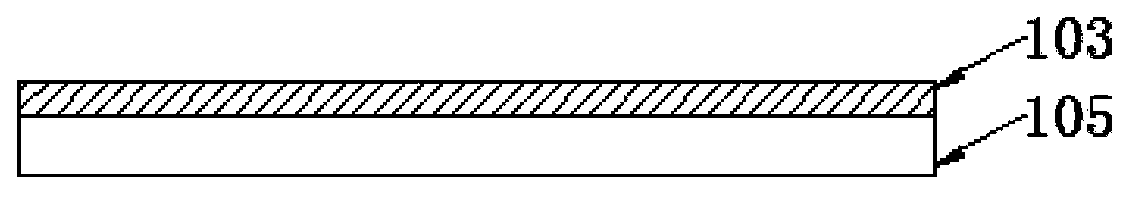

[0026] The first copper foil layer 103 and the second copper foil layer 104 are ultra-thin carrier copper foils of 9um and below, which are difficult to take because they are easy to wrinkle, and need to be supported by a carrier layer (such as figure 2 as shown, figure 2 Take the first copper foil layer 103 as an example, and 105 is the carrier layer).

[0027] The carrier copper foil used ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com